Method for preparation of tobacco flavor by using compound enzymes to catalyze abandoned tobacco waste

A tobacco flavoring and compound enzyme technology, which is applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of complicated processing equipment, environmental pollution, waste of resources, etc., and achieve the effects of natural processing, cost reduction, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037](1) Reaction: Weigh 10g of waste tobacco powder and a glass reaction bottle with a stopper, add 150mL mass concentration of 1% mannanase, 1% ficinase, 1% glucoamylase, 1% α-amylase, 1% xylanase, 1% pectinase and 1% lipase, 5% pectinase (the mannanase activity ≥ 1000000MNU / g, ficinase activity ≥ 500000MCU / g, glucoamylase activity ≥ 40000μ / g, amylase activity≥40000μ / g, xylanase activity≥1000000μ / g, lipase activity≥1000000LUN / g, pectinase activity≥124000μ / g, all provided by Shanghai Baofeng Biochemical Co., Ltd.) Composite enzyme buffer aqueous solution (pH 5.05), react at 50°C for 24 hours;

[0038] (2) Extraction: After the reaction, filter with non-woven fabric, extract the aqueous solution with 50 mL of ether, extract twice, and extract the filter residue with 50 mL of ether for 15 minutes, and combine the ether phases;

[0039] (3) Concentration: Concentrate the ether phase at 36°C and 850mbar, freeze at -80°C, remove insoluble matter such as wax and fat, and further ...

Embodiment 2

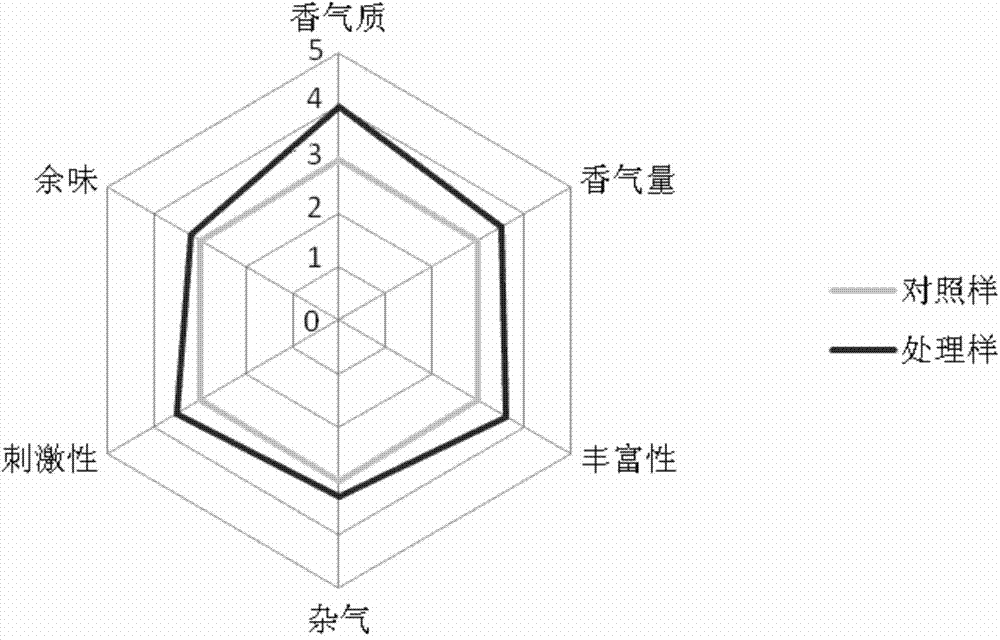

[0050] Use the same volume of water and composite enzyme buffer solution aqueous solution to extract tobacco powder simultaneously, carry out comparative experiment, experimental method is as described in embodiment 1, wherein only composite enzyme buffer solution aqueous solution is replaced by water when using water extraction, other methods are all same. GC / MS was used to compare the changes of some aroma components between the control sample (without enzyme) and the addition of compound enzymes. The results showed that after the compound enzyme post-treatment, the content of solanone was 2.7 times that of the control sample, and damascenone was 2.7 times that of the control sample. 2.2 times, 3-oxo-alpha-ionol is 2.9 times that of the control, benzyl alcohol is 7.1 times that of the control, phenylethyl alcohol is 6.2 times that of the control, 3-hydroxy-beta-damascone is 1.7 times, and giant soybean three Enone 1, 2, 3 and 4 are 1.2 times, 1.4 times, 1.4 and 1.5 times res...

Embodiment 3

[0052] (1) Reaction: Weigh 10g of waste tobacco powder and a glass reaction bottle with a stopper, add 200mL mass concentration of 0.5% mannanase, 2% ficinase, 2% glucoamylase, 2% α-amylase, 0.5% xylanase, 0.5% pectinase and 2% lipase, 3% pectinase (the mannanase activity ≥ 1000000MNU / g, ficinase activity ≥ 500000MCU / g, glucoamylase activity ≥ 40000μ / g, amylase activity≥40000μ / g, xylanase activity≥1000000μ / g, lipase activity≥1000000LUN / g, pectinase activity≥124000μ / g, all provided by Shanghai Baofeng Biochemical Co., Ltd.) Composite enzyme buffer aqueous solution (pH 4.2), react at 45°C for 28h;

[0053] (2) Extraction: After the reaction, filter with non-woven fabric, extract the aqueous solution with 50mL ether, extract twice, extract the filter residue with 40mL ether ultrasonically for 25min, and combine the ether phases;

[0054] (3) Concentration: Concentrate the ether phase at 36°C and 850mbar, freeze at -80°C, remove insoluble matter such as wax and fat, and further c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com