Composite visible light photocatalyst and its preparation method

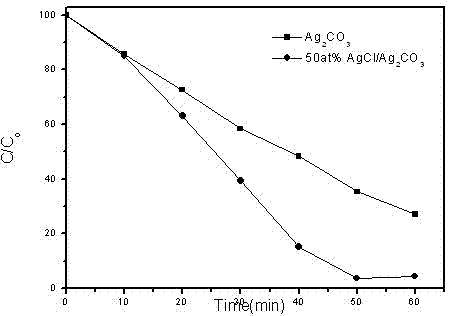

A photocatalyst and visible light technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low utilization rate and poor stability of visible light, and achieve large-scale promotion and low cost. The effect of low and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

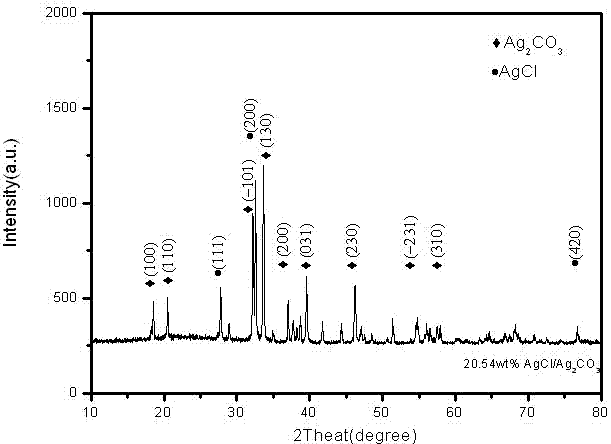

[0023] Visible light responsive AgX / Ag of the present invention 2 CO 3 (X=Cl, I) the preparation method of composite photocatalyst specifically comprises the following steps:

[0024] In the first step, place silver carbonate in an aqueous solution for ultrasonic dispersion for 20-40 minutes to obtain a silver carbonate dispersion, and the mass ratio of silver carbonate to water is 0.1:100~1:100.

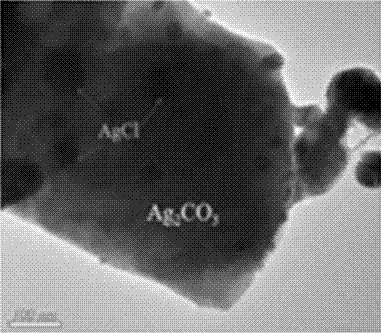

[0025] In the second step, the halogenated ionic liquid ([C n min]X (X=Cl, I, n=4-16)) into deionized water, fully dissolved to form a halogenated ionic liquid solution; the mass ratio of the halogenated ionic liquid to water is 0.1:100~2:100; The role of the ionic liquid is to make the silver halide uniformly dispersed in the Ag 2 CO 3 surface, forming a heterojunction structure.

[0026] The third step is to add the prepared halogenated ionic liquid solution dropwise to the solution obtained in the first step under the condition of heating at 40-60°C in a water bath and stir...

Embodiment 1

[0029] Embodiment 1: AgCl / Ag of visible light response of the present invention 2 CO 3 (4.92 wt%) preparation method of composite photocatalyst, specifically comprises the following steps:

[0030] In the first step, 0.278 g of silver carbonate was ultrasonically dispersed in 30 ml of deionized water for 20 minutes to obtain a silver carbonate dispersion.

[0031] In the second step, 0.034 g of [C 16 min]Cl chlorinated ionic liquid was added into 20 ml of deionized water and fully dissolved to form a chlorinated ionic liquid solution.

[0032] The third step is to add the prepared chlorinated ionic liquid solution dropwise to the solution obtained in the first step under the condition of heating at 40° C. in a water bath and stirring uniformly, and continue stirring for 160 minutes after the dropwise addition is completed.

[0033] In the fourth step, the product obtained in the third step reaction is washed three times with deionized water and absolute ethanol respectively...

Embodiment 2

[0034] Embodiment 2: AgCl / Ag of visible light response of the present invention 2 CO 3 (13.43 wt%) The preparation method of composite photocatalyst specifically comprises the following steps:

[0035] In the first step, 0.278 g of silver carbonate was ultrasonically dispersed in 30 ml of deionized water for 30 minutes to obtain a silver carbonate dispersion.

[0036] In the second step, 0.103 g of [C 16 min]Cl chlorinated ionic liquid was added into 20 ml of deionized water and fully dissolved to form a chlorinated ionic liquid solution.

[0037] The third step is to add the prepared chlorinated ionic liquid solution dropwise to the solution obtained in the first step under the condition of heating in a water bath at 50° C. and stirring uniformly, and continue stirring for 170 minutes in shading after the dropwise addition is completed.

[0038] In the fourth step, the product obtained in the third step reaction is washed three times with deionized water and absolute ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com