Efficient hardness removal method and device applicable to underground water

A groundwater and hardness technology, which is applied in the field of water treatment, can solve the problems of complex lime softening process, large floor area, and low effective utilization rate of lime, so as to save resource consumption, reduce floor space, reduce equipment investment and operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

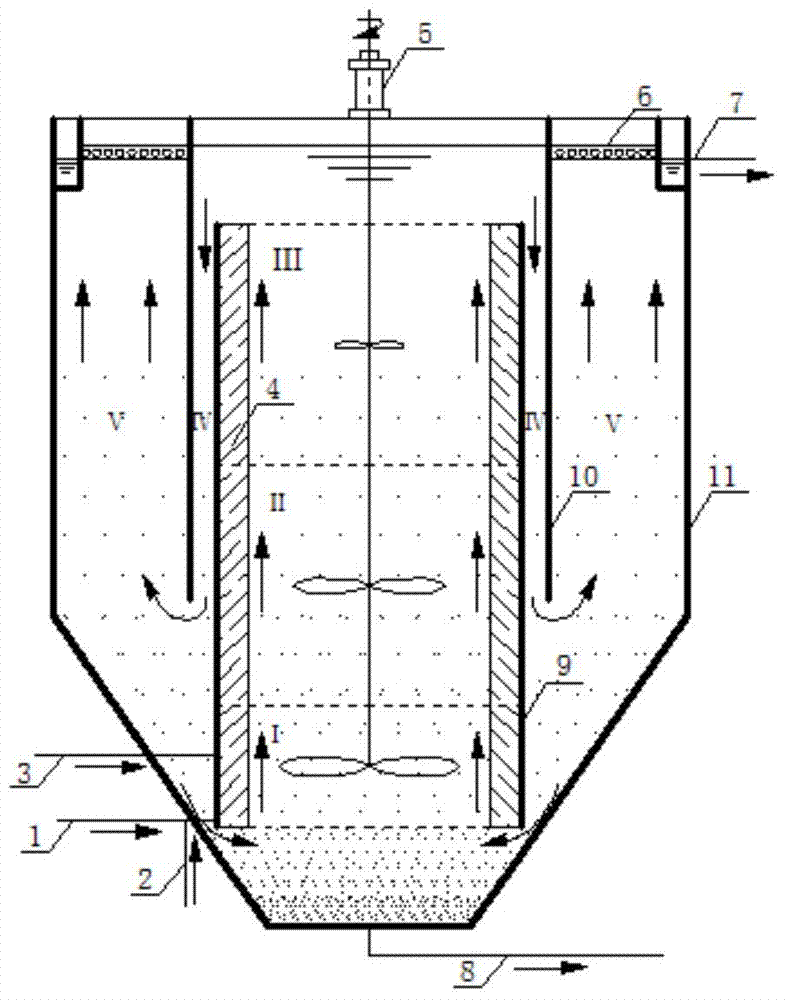

Embodiment 1

[0023] Processing flow Q=10m 3 / h, the effective volume of the groundwater hardness removal device is 9.1m 3 , where the volumes of reaction zones I, II, and III are 0.417m 3 、0.833m 3 、0.833m 3 , the volume of the sedimentation zone is 6.67m 3 . The speed of the inclined-blade paddle agitator is 430r / min, and the angles of the paddle blades distributed in the three reaction zones are all 45°. The lengths of the blades are 650mm, 550mm and 250mm from bottom to top, and the widths are 65mm, 55mm and 25mm respectively. . The raw water is groundwater with a total hardness of 390mg / L and a total alkalinity of 320mg / L. The concentration of milk of lime is 3%, FeCl 3 The concentration of the solution is 5%, the dosage of CaO is 225mg / L, FeCl 3 The dosage is 5mg / L, and the turbidity of the effluent and the total hardness of the filtered effluent are monitored. After the device runs for 1 hour, the milk of lime and CaCO in the sediment 3 It has accumulated to a certain exten...

Embodiment 2

[0025] Processing flow Q=10m 3 / h, the effective volume of the groundwater hardness removal device is 9.1m 3 , where the volumes of reaction zones I, II, and III are 0.417m 3 、0.833m 3 、0.833m 3 , the volume of the sedimentation zone is 6.67m 3. The speed of the inclined-blade paddle agitator is 430r / min, and the angles of the paddle blades distributed in the three reaction zones are all 45°. The lengths of the blades are 650mm, 550mm and 250mm from bottom to top, and the widths are 65mm, 55mm and 25mm respectively. . The raw water is groundwater with a total hardness of 390mg / L and a total alkalinity of 320mg / L. The concentration of milk of lime is 3%, AlCl 3 The concentration of the solution is 5%, the dosage of CaO is 225mg / L, AlCl 3 The dosage is 7mg / L, and the turbidity of the effluent and the total hardness of the filtered effluent are monitored. After the device runs for 1 hour, the milk of lime and CaCO in the sediment 3 It has accumulated to a certain extent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com