Super-strength transparent imitated shell composite thin film and preparation method thereof

A composite film and shell imitation technology, which is applied in the field of bionics, can solve the problem of not being able to imitate shell organic matter bridges in a green and fast manner, and achieve the effects of low cost of raw materials, broad application prospects, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a super-strength transparent imitation shell composite film and a preparation method thereof. The preparation method specifically includes the following steps:

[0028] The first step is to prepare MMT colloid;

[0029] Dissolving MMT in distilled water to form a 0.2-2wt% MMT aqueous solution, then stirring with a magnetic stirrer for at least 1 week, centrifuging the supernatant obtained is the MMT colloid peeled into a single piece;

[0030] In the second step, the obtained MMT colloid and ALG aqueous solution are mixed, stirred until fully mixed to obtain a mixed solution; the mass percent concentration of the ALG aqueous solution is 0.1 to 1 wt %; the mass ratio of MMT and ALG in the mixed solution is 1:9 to 1 :1.

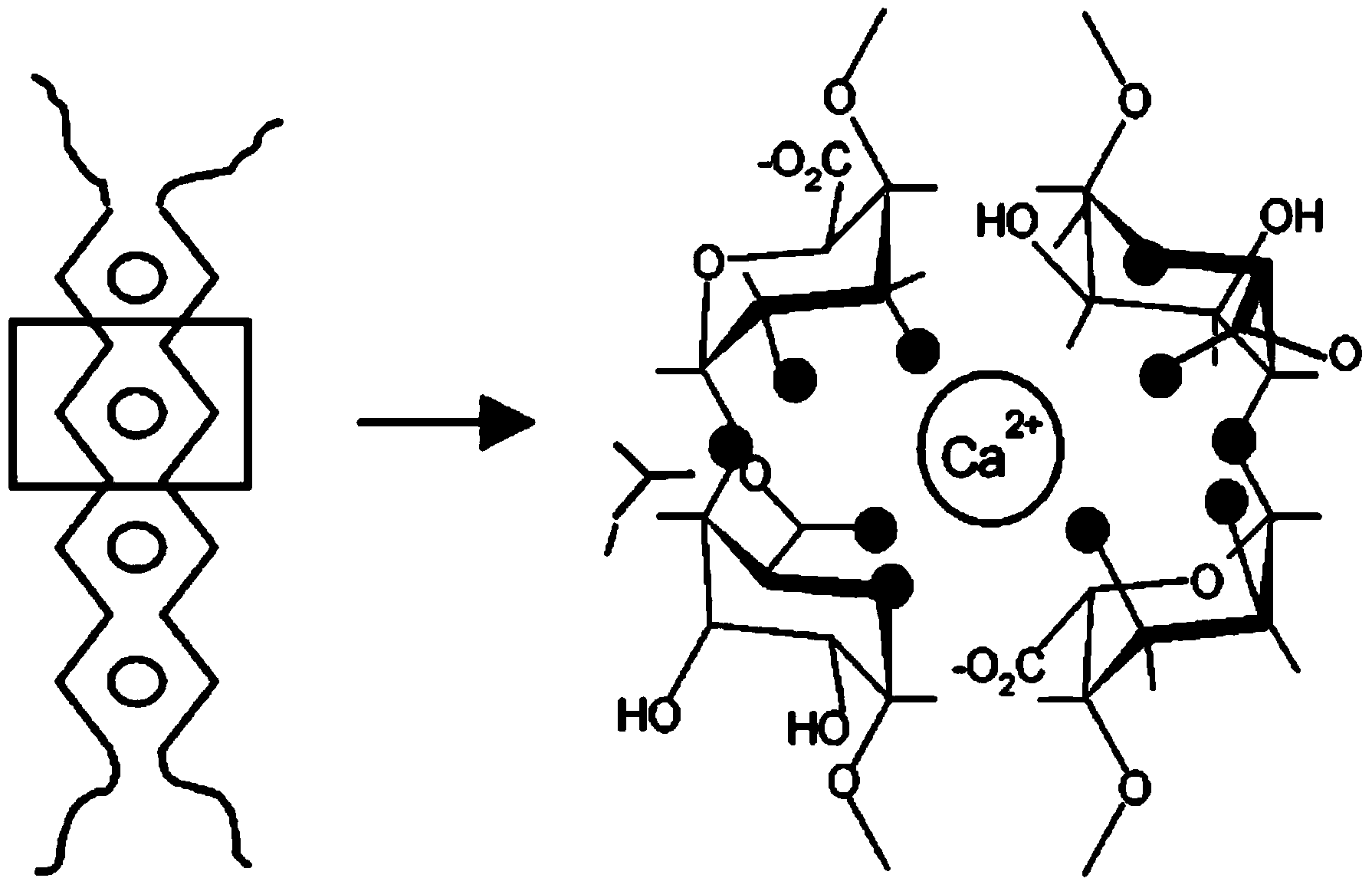

[0031] In the third step, add CaCl to the mixed solution in the second step 2 , stir to make it well mixed, since Ca 2+ Coupled with ALG to form a figure 1 The egg-box structure shown in; the CaCl 2 The mass of ALG is 10-200% ...

Embodiment 1

[0035] In the first step, 0.2g of MMT was dissolved in 100g of distilled water to form a 0.2wt% MMT aqueous solution, then stirred with a magnetic stirrer for 1 week, and the supernatant obtained by centrifugation was the MMT colloid peeled into a single piece;

[0036] In the second step, the obtained MMT supernatant is mixed with 1 wt% ALG aqueous solution, and stirred until fully mixed to obtain a mixed solution; the mass ratio of MMT and ALG in the mixed solution is 1:9.

[0037] In the third step, add an appropriate amount of CaCl to the mixed solution in the second step 2 , stir to make it well mixed, since Ca 2+ Coupled with ALG to form a figure 1 The egg box structure shown in; the added CaCl 2 The quality is 200% of the ALG quality.

[0038] In the fourth step, the solution is vacuum filtered to obtain the super-strength transparent imitation shell composite film of the present invention.

[0039] Under the action of vacuum, the MMT sheet and the egg box structure f...

Embodiment 2

[0041] In the first step, 1g of MMT was dissolved in 100g of distilled water to form a 1wt% MMT aqueous solution, then stirred with a magnetic stirrer for 1 week, and the supernatant obtained by centrifugation was the MMT colloid peeled into a single piece;

[0042] In the second step, the obtained MMT supernatant and 1wt% ALG aqueous solution were mixed and stirred until fully mixed to obtain a mixed solution; the mass ratio of MMT and ALG in the mixed solution was 1:1.

[0043] In the third step, add an appropriate amount of CaCl to the mixed solution in the second step 2 , stir to make it well mixed, since Ca 2+ Coupling with ALG to form an egg-box structure; the added CaCl 2 The quality is 100% of ALG quality.

[0044] In the fourth step, the solution is vacuum filtered to obtain the super-strength transparent imitation shell composite film of the present invention.

[0045] Under the action of vacuum, the MMT sheet and the egg box structure formed by the coupling form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile stress | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com