Device and method for joint evaluation of denitration and demercuration performances of catalyst

A mercury removal performance and catalyst technology, applied in the direction of chemical analysis using catalysis, can solve problems such as complex flue gas composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

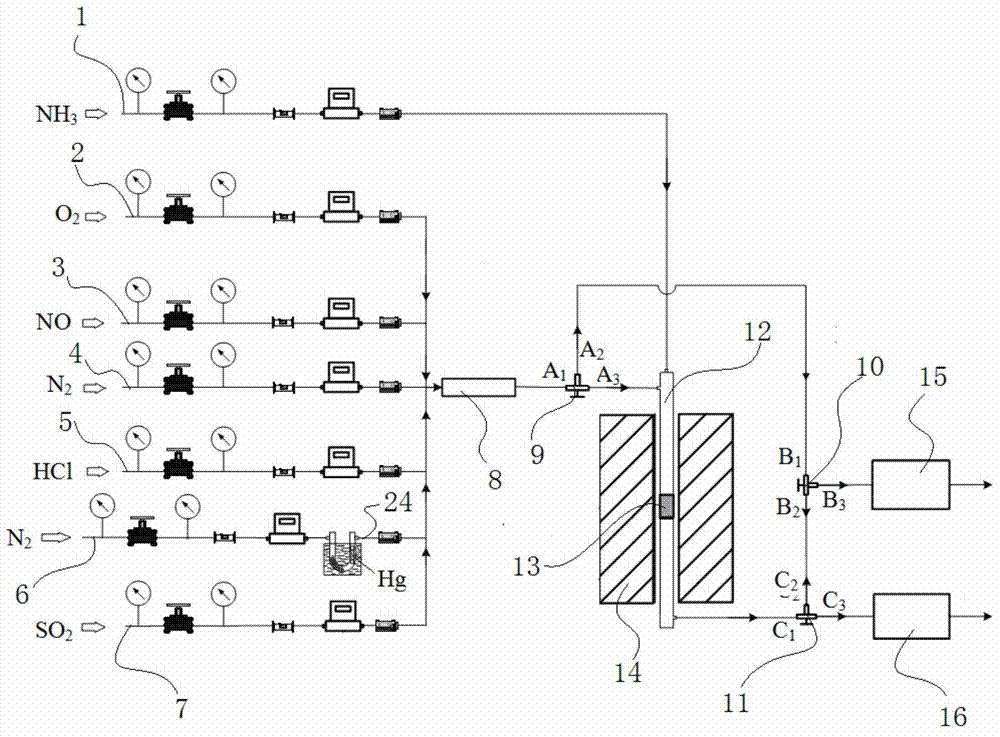

[0026] A device for joint evaluation of catalyst denitration and mercury removal performance, including pipelines I to VII, preheating mixer 8, three-way ball valve I to III, flue gas analyzer 15 and mercury analyzer 16, and two air inlets And a catalytic reactor 12 with an outlet. The catalytic reactor 12 is a vessel containing a catalyst inside. The gas entering from any inlet of the catalytic reactor 12 flows through the catalyst (usually fixed on a carrier) and is discharged from the outlet.

[0027] The inlet of the pipeline I1 is connected to NH 3 The gas source and the outlet are connected to the first air inlet of the catalytic reactor 12.

[0028] The inlet of the pipe Ⅱ 2 is connected to O 2 The air source and outlet are connected to the air inlet of the preheating mixer 8. The inlet of the pipe III3 is connected to the NO gas source, and the outlet is connected to the air inlet of the preheating mixer 8. The inlet of the pipe IV4 is connected to N 2 The air source and...

Embodiment 2

[0034] In this embodiment, the device described in embodiment 1 is used to jointly evaluate the performance of catalyst denitration and mercury removal, including the following steps:

[0035] 1) Adjust the three-way ball valve I9 so that A 1 Mouth and A 2 Port connection, A 3 The port is closed, adjust the three-way ball valve Ⅱ10, so that B 1 Mouth, B 2 口和B 3 The ports communicate with each other, adjust the three-way ball valve Ⅲ11 so that C 2 口和C 3 Port connection, C 1 The mouth is closed. Even if the mixed gas from the preheating mixer 8 does not pass through the catalyst 13, it directly enters the flue gas analyzer 15 and the mercury analyzer 16.

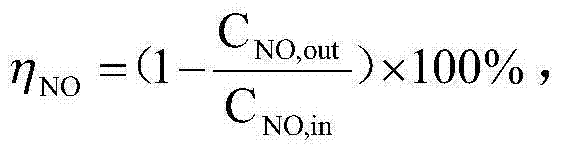

[0036] 2) Pass O into the preheating mixer 8 through pipes Ⅱ~Ⅷ 2 , NO, N 2 , Mercury vapor, HCl and SO 2 gas. At this time, the one-way valve 22 on the pipeline I is closed. The flue gas analyzer 15 detects the initial concentration C of NO NO,in , The mercury analyzer 16 detects the initial concentration of mercury vapor [Hg 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com