Preparation method for bismuth phosphate photocatalyst with different microstructures

A photocatalyst and microscopic morphology technology, applied in the field of photocatalysis, can solve the problems of difficult separation and recovery, high photogenerated hole-electron recombination rate, low utilization rate of sunlight, etc., and achieve low cost, simple and easy preparation method, Avoid the effects of the hydrothermal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

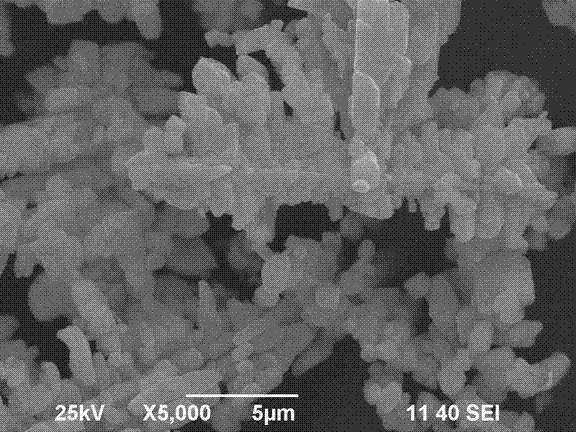

Embodiment 1

[0014] Dissolve 1 mmol of bismuth nitrate in 50 ml of nitric acid solution with a molar concentration of 0.5 mol / L, add 0.5 mmol of EDTA disodium salt, stir well, then add 1 mmol of sodium dihydrogen phosphate to obtain a mixed solution; Add a sodium hydroxide solution with a molar concentration of 1 mol / L to adjust the pH of the system to 1, and let it stand at room temperature for 60 hours to obtain a precipitate; centrifuge the precipitate, wash it, dry it, and then calcinate it at 400°C. Obtain cypress leaf bismuth phosphate photocatalyst. Depend on figure 1 It can be seen that the prepared bismuth phosphate photocatalyst is cypress leaf-shaped, with good dispersion and regular appearance.

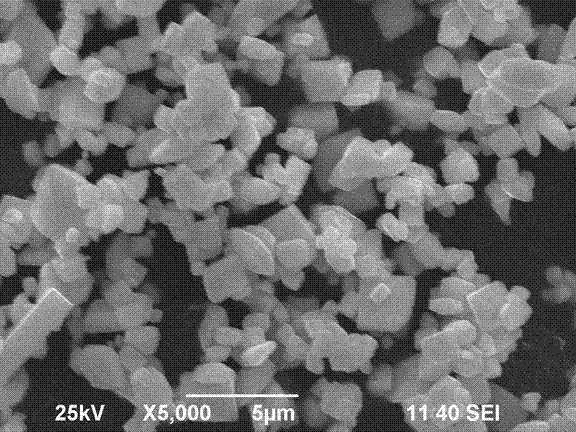

Embodiment 2

[0016] Dissolve 2 mmol of bismuth nitrate in 50 ml of nitric acid solution with a molar concentration of 3 mol / L, add 0.5 mmol of EDTA disodium salt, stir well, then add 2 mmol of sodium dihydrogen phosphate to obtain a mixed solution; Add sodium hydroxide solution with a molar concentration of 3 mol / L, adjust the pH of the system to 1, and let it stand at room temperature for 120 hours to obtain a precipitate; centrifuge the precipitate, wash it, dry it, and then calcinate it at 600°C. A cube-shaped bismuth phosphate photocatalyst was obtained. Depend on figure 2 It can be seen that the prepared bismuth phosphate photocatalyst is cube-shaped, with good dispersion and regular shape.

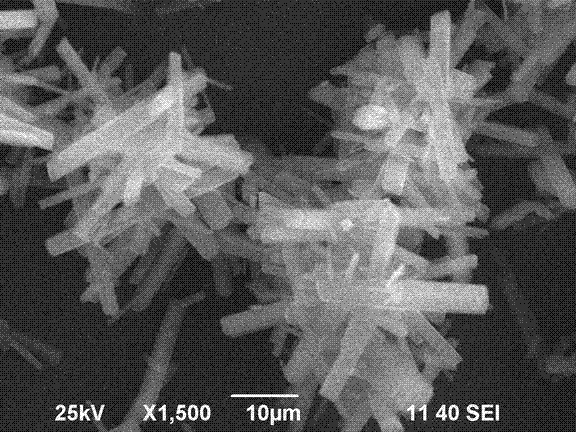

Embodiment 3

[0018] Dissolve 1 mmol of bismuth nitrate in 50 ml of nitric acid solution with a molar concentration of 1 mol / L, add 2 mmol of EDTA disodium salt, stir well, then add 1 mmol of sodium dihydrogen phosphate to obtain a mixed solution; Add a sodium hydroxide solution with a molar concentration of 0.5 mol / L, adjust the pH of the system to 1, and let it stand at room temperature for 1 hour to obtain a precipitate; centrifuge the precipitate, wash it, dry it, and then calcinate it at 400°C. Pine needle-like bismuth phosphate photocatalyst. Depend on image 3 It can be seen that the prepared bismuth phosphate photocatalyst is pine needle-shaped, with good dispersion and regular shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com