Method for processing high-reflectance material based on metal nanoparticle photothermal effect

A technology of metal nanoparticles and high reflectivity, which is applied in metal processing equipment, metal material coating technology, manufacturing tools, etc., can solve the problems of increasing the overall cost and low fault tolerance rate, so as to improve the absorption rate, improve the processing efficiency, Effect of increasing laser utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

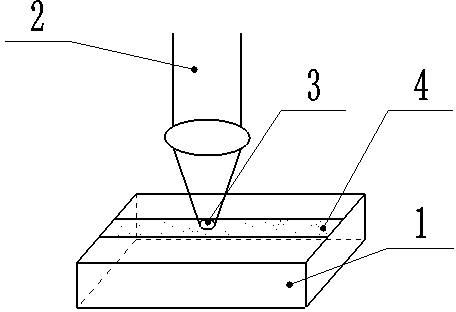

[0018] Take the high reflectivity material copper plate as an example, such as figure 1 As shown, before the laser processing of the high-reflectivity material copper plate 1, a layer of copper nanoparticles 3 is distributed on the area 4 of the material to be processed. Wherein, the reflectivity of the high-reflectivity material copper plate 1 is above 80%, and the thickness range of the high-reflectivity material copper plate 1 is 1000-1000000nm. The size of the copper nanoparticles 3 is tens of nanometers to hundreds of nanometers, preferably 10 to 100 nm. The size of the metal nanoparticles in this range is more uniform and easier to control during the preparation process, and the metal nanoparticles in this range The matting of the particles is dominated by absorption. In addition, the shape of the copper nanoparticles 3 is not limited, and may be various three-dimensional geometric shapes such as spherical, rod, shell, cage, cluster, star, triangle or other irregular sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com