Coke wastewater advanced treatment method utilizing catalytic internal electrolysis technology and coupled two-stage bio-filter

A biofilter and coking wastewater technology, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the unsatisfactory removal effect of refractory and refractory organic matter , It is difficult to achieve the treatment effect and other problems, and achieve the effect of simple process, easy promotion and application, and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

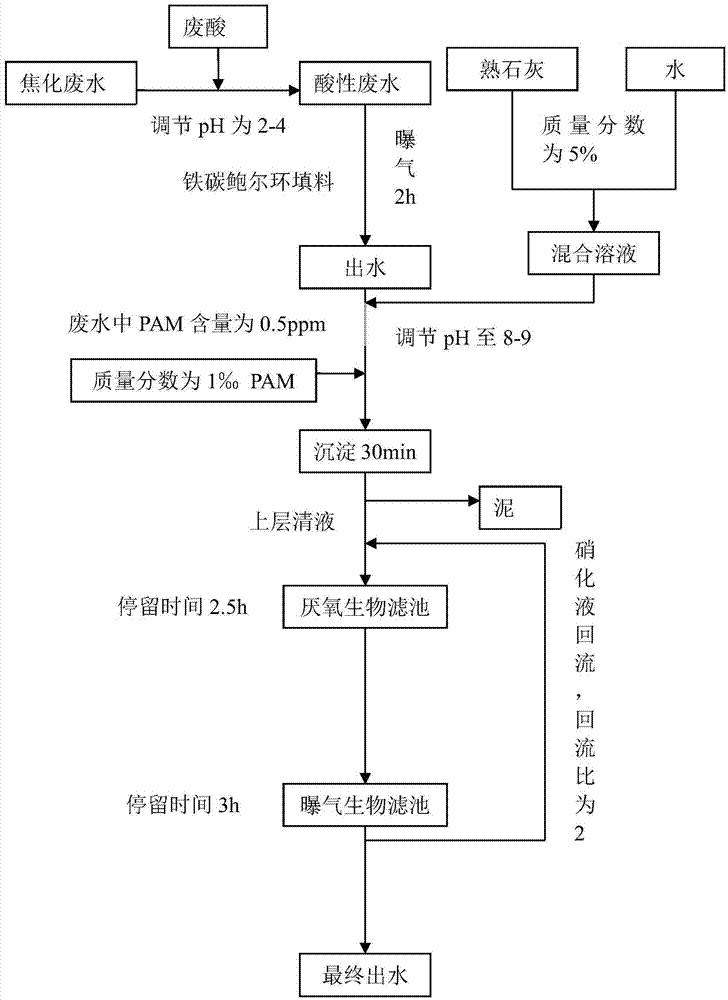

[0025] please see figure 1 .

[0026] Biochemical effluent (COD) from a coking plant Cr 290mg / L, NH 3 -N is 21mg / L, TN is 60mg / L, and chromaticity is 250 times) Add a certain amount of waste acid solution into the wastewater, stir, and adjust the pH value of the wastewater to about 3.

[0027] Add self-made iron-carbon Pall ring fillers to the wastewater, add fillers at a ratio of 10 fillers / L wastewater, aerate for 2 hours, and discharge water;

[0028] According to the configuration of slaked lime: water = 5: 100 (mass ratio), stir evenly to obtain a mixed solution, add the mixed solution to the wastewater effluent after internal electrolytic aeration, and the dosage of the mixed solution depends on the pH value of the effluent to 8 ~9 shall prevail;

[0029] Then add commercially available anionic polyacrylamide, so that the content of polyacrylamide in the wastewater is 0.5ppm. After stirring for half an hour, let it stand for half an hour to settle, and then detect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com