Preparation method of sintered corundum with good wear resistance

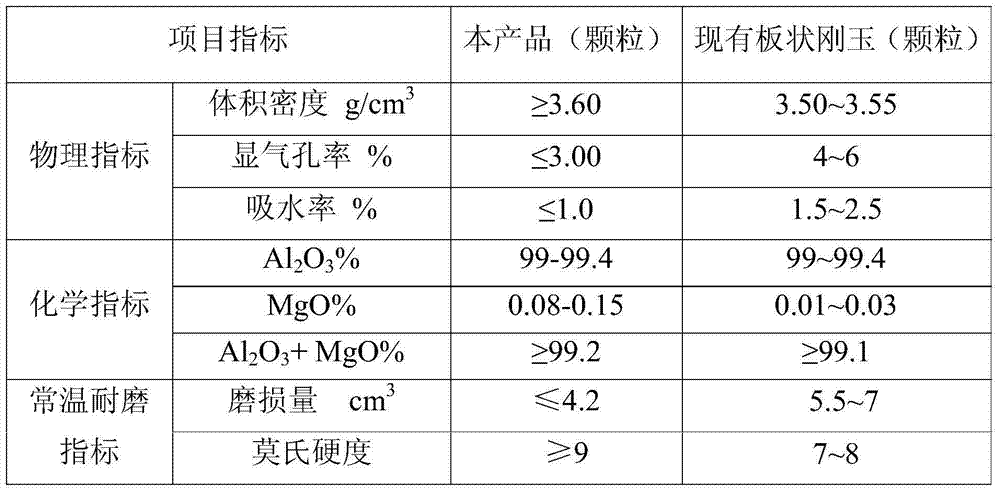

A technology for sintering corundum and wear resistance, applied in the field of refractory materials, can solve the problems of low bulk density, high sintering temperature, and product purity decrease, and achieve the effect of high bulk density, compact crystal structure and low impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

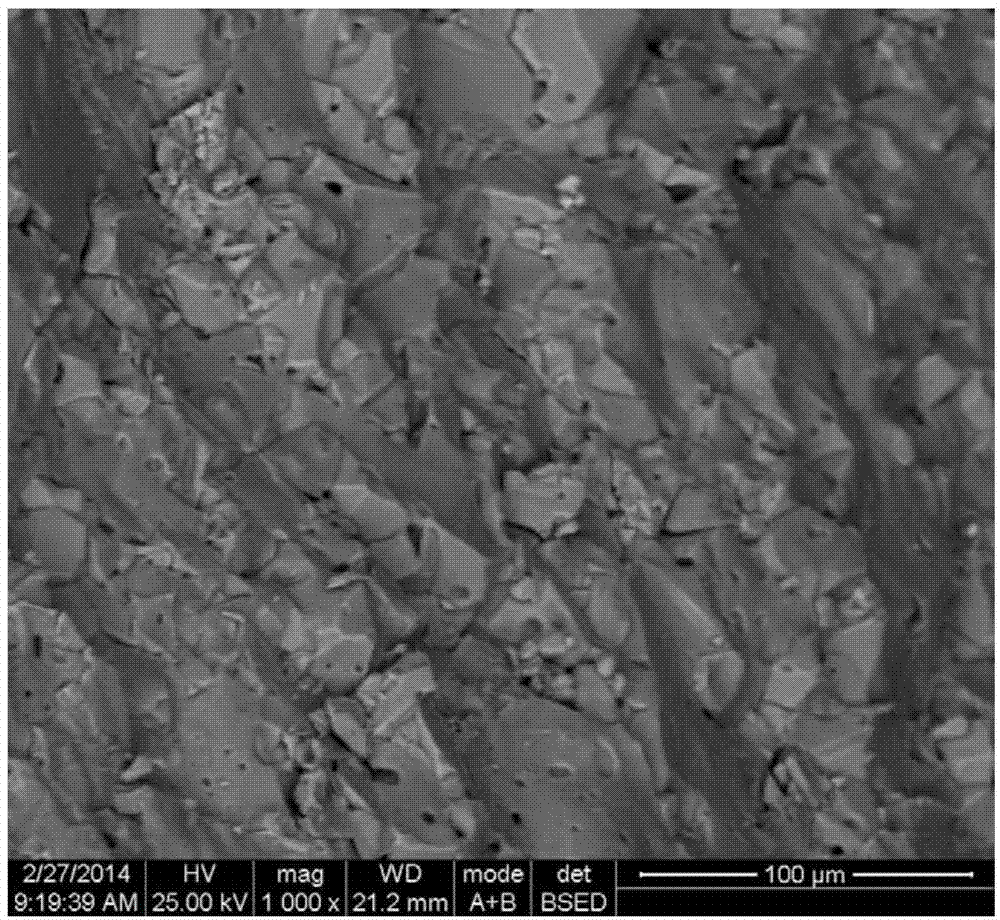

Image

Examples

Embodiment 1

[0033] A method for preparing sintered corundum with good wear resistance, the process flow is:

[0034] (1) Select raw materials

[0035] Select common industrial γ-Al 2 o 3 and seawater magnesia as raw materials, of which the general industrial γ-Al 2 o 3 Particle size requirement -60 mesh ≥ 90.0%, Al2 o 3 %≥98.5%, SiO 2 %≤0.04%, R 2 O%≤0.55%; seawater magnesia particle size requirements -200 mesh ≥90.0%, MgO%≥98%, SiO 2 %≤0.3%, CaO≤1.0%, Fe 2 o 3 ≤0.15%.

[0036] In the present invention, unless otherwise specified, percentages are percentages by weight.

[0037] (2) mixed

[0038] Weigh 950kg of γ-Al 2 o 3 Mix with the seawater magnesia of 50kg in planetary mixer, obtain mixture.

[0039] (3) grinding

[0040] Put the mixture in step (2) into a tube mill for dry grinding to obtain a mixed powder. The mass ratio of grinding balls is large ball (diameter 50mm): small ball (diameter 30mm) = 1:4, the feed rate is 95kg / h, the speed of classifier is 900r / min, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com