Antistatic anti-yellowing PP/POE plastic for automotive interior parts and preparation method thereof

An automobile interior parts, antistatic technology, applied in antistatic and anti-yellowing PP/POE plastics for automobile interior parts and its preparation, modified PP/POE plastics and its preparation fields, can solve the problem of PP/POE plastics anti-static Unsatisfactory static electricity and anti-yellowing properties, restricting applications, etc., to achieve the effects of low product cost, simple preparation process, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

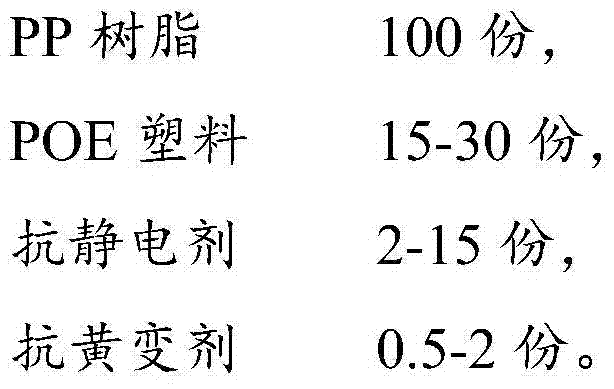

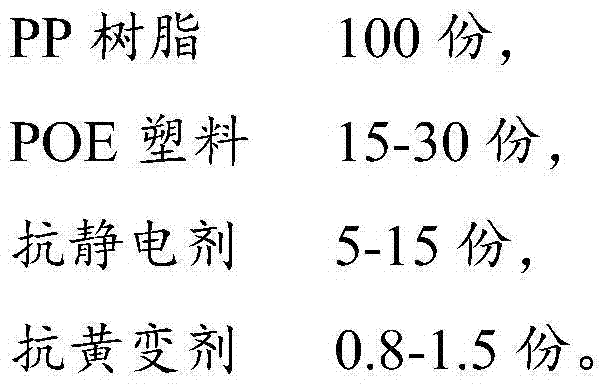

Method used

Image

Examples

Embodiment 1

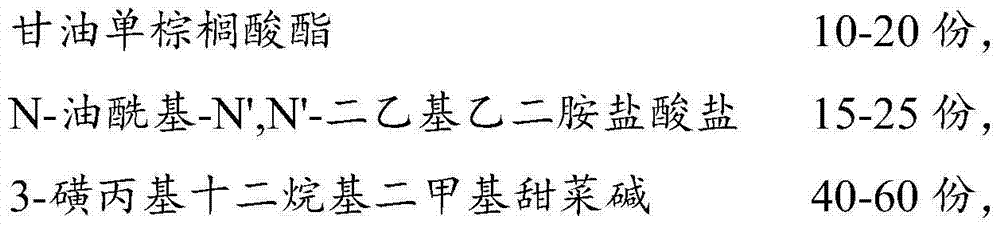

[0044] Weigh each antistatic agent component according to the corresponding embodiment 1 data in table 1, after fully mixing, obtain the composite antistatic agent of embodiment 1;

[0045] Get 100 kilograms of PP resin after the drying treatment, 20 kilograms of POE plastics, 1.5 kilograms of dibutyl hydroxytoluene and the compound antistatic agent of embodiment 1, after fully mixing at high speed for 10 minutes, add the feeding port of the twin-screw extruder Control the speed of the twin-screw extruder at 300rpm, the temperature at 200°C, and extrude and granulate through the twin-screw extruder to obtain the antistatic and anti-yellowing PP / POE plastic for automotive interior parts of Example 1.

[0046] Table 1: PP / POE plastic antistatic agent formula table of embodiment 1-7 Unit: kg

[0047]

Embodiment 2

[0049] Take each antistatic agent component according to the corresponding embodiment 2 data in table 1, after fully mixing, obtain the composite antistatic agent of embodiment 2;

[0050] According to the method described in Example 1, the antistatic and anti-yellowing PP / POE plastics for automotive interior parts of Example 2 were obtained.

Embodiment 3

[0052] Take each antistatic agent component according to the corresponding embodiment 3 data in table 1, after fully mixing, obtain the composite antistatic agent of embodiment 3;

[0053] According to the method described in Example 1, the antistatic and anti-yellowing PP / POE plastic for automotive interior parts of Example 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com