High-power resonance wave-chemical composite profile control and flooding device and method

A resonant wave, high-power technology, applied in the field of high-power resonant wave-chemical compound drive control devices, can solve problems such as construction conflicts, and achieve the effects of low input cost, reasonable design, and prolonged action period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

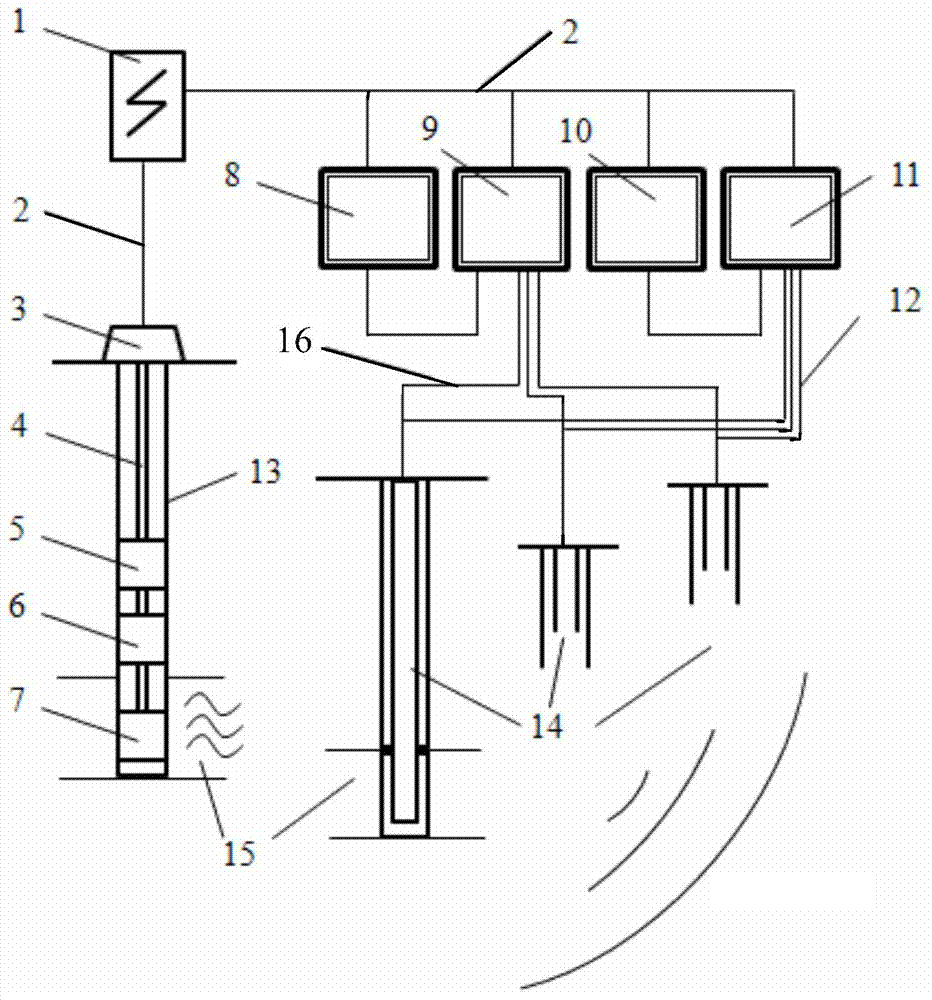

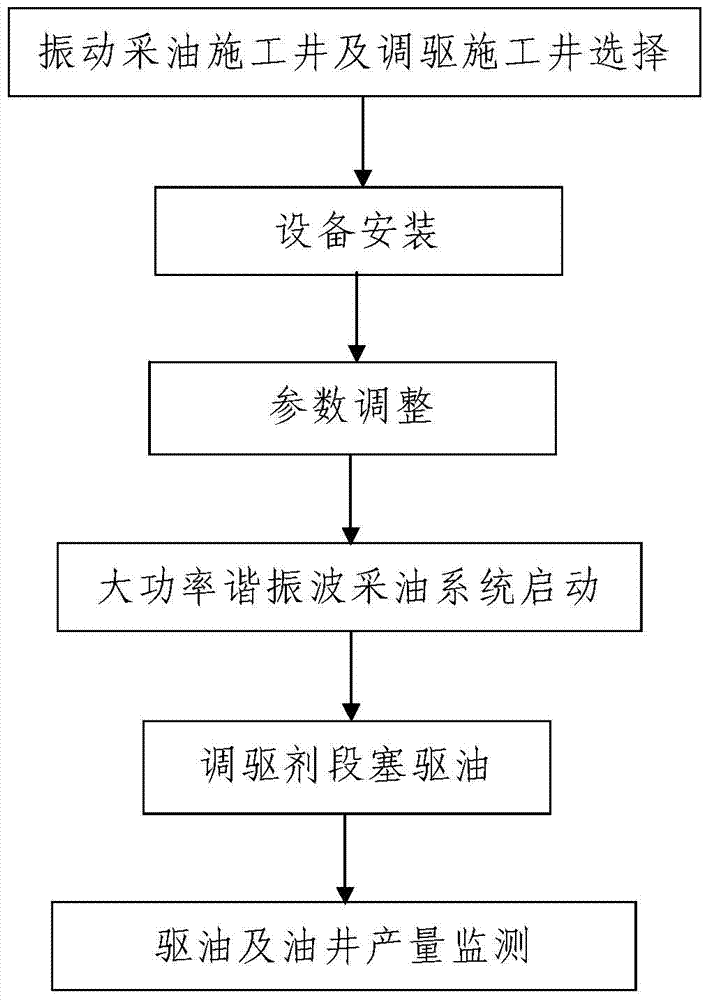

[0054] like figure 1 A high-power resonant wave-chemical composite control and flooding device shown includes a high-power resonant wave oil production system and chemical control and drive equipment. The high-power resonant wave oil production system includes a vibration generator 5 for generating mechanical vibrations, located at On the ground and the vibration driving equipment 3 that vibration generator 5 is driven, the vibration amplitude amplifying mechanism 6 that amplifies the amplitude of the mechanical vibration generated by the vibration driving equipment 3 and the mechanical vibration direction amplified by the vibration amplitude amplifying mechanism 6 Transform the vibration direction converter 7 to apply mechanical vibration to the oil reservoir 15 under construction. The vibration waveform of the mechanical vibration generated by the vibration generator 5 is a harmonic wave. The power of the Xie Zhenbo is 30kW~120kW. The reservoir 15 is an oil reservoir located...

Embodiment 2

[0103] In this embodiment, the high-power resonant wave-chemical composite control and drive device used is the same as that in Embodiment 1.

[0104] In this embodiment, when the profile control agent injected in Step 5 is a jelly-type profile control agent, a gel-type profile control agent or a resin-type profile control agent, the high-power resonant wave-chemical composite control and drive device does not need A gas compressor 8, a gas injection skid 9 and a gas injection line 16 are used.

[0105] In this example, the high-power resonant wave-chemical composite control and flooding method adopted is different from that in Example 1 in that the flood control agent injected in Step 5 is jelly type profile control agent, gel type profile control agent or resin type Profile control agent, step 5: when carrying out slug displacement of the control and displacement agent, inject the control and displacement agent into the construction well 14 through the agent injection pipeli...

Embodiment 3

[0116] In this embodiment, the difference between the high-power resonant wave-chemical compound control and drive device used in Embodiment 1 is that the vibration drive device 3 is an electric vibration exciter, an electromagnetic vibration exciter, an electro-hydraulic vibration exciter, etc. actuator or hydraulic vibration exciter. The mechanical vibration generated by the vibration generator 5 is transmitted to the vibration amplitude amplification mechanism 6 through the vibration transmission mechanism 4 , and the mechanical vibration amplified by the vibration amplitude amplification mechanism 6 is transmitted to the vibration direction converter 7 through the vibration transmission mechanism 4 .

[0117] In this embodiment, the vibration driving device 3 is an electromagnetic vibration exciter.

[0118] In actual use, the electromagnetic vibration exciter can be the electromagnetic vibrator disclosed in the invention patent application "An Electromagnetic Drive Downho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com