Measurement and control method for engine coolant temperature sensor, and measurement and control system thereof

An engine coolant and temperature sensor technology, which is applied in thermometer testing/calibration, thermometers, instruments, etc., can solve problems such as low efficiency, unintuitive and accurate testing and calibration, and poor control of testing and calibration, achieving high efficiency, Intuitive, HMI-friendly results for testing and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

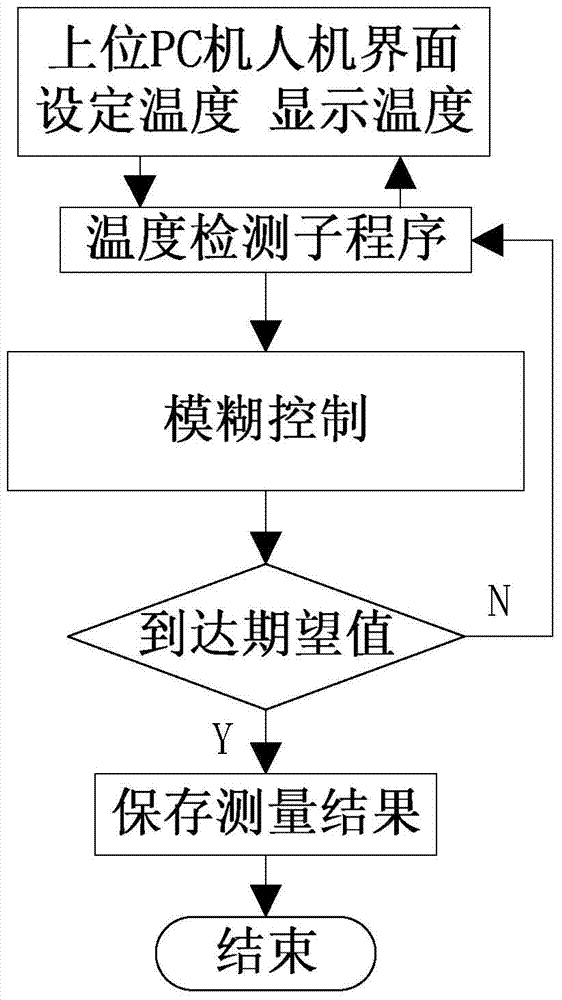

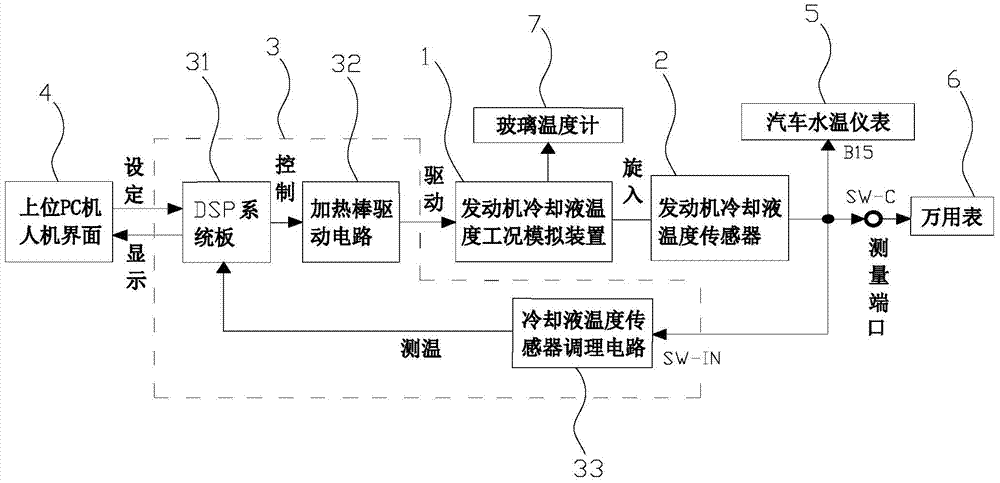

[0024] The engine coolant temperature sensor measurement and control method of the present invention comprises:

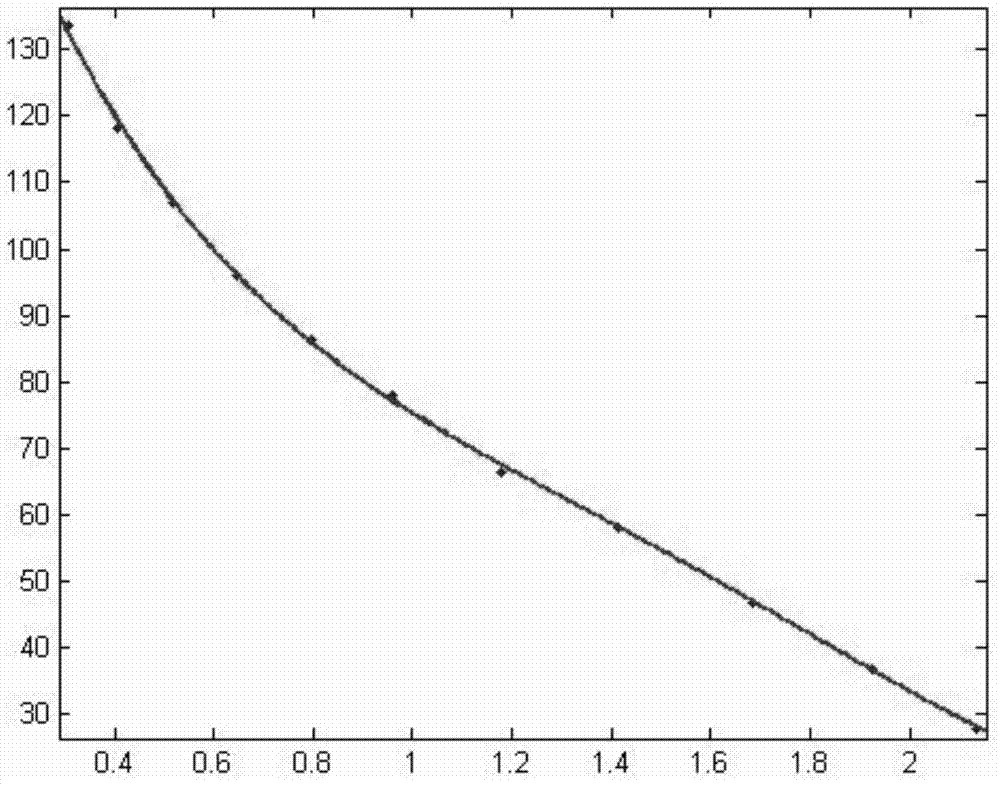

[0025] First of all, the median filter method is used to process the AD conversion value. Since the median filter involves the numerical sorting problem, in order to ensure sufficient sampling accuracy, the number of oversampling for a certain point must be relatively large, and the efficiency of the sorting algorithm must be considered The problem is that the Hill sorting method with high efficiency is selected for this purpose; the time complexity of the Hill sorting method is O(n), and the Hill sorting method requires that the number n to be sorted be an integer multiple of 4, so the number of sorting n= 128. In theory, compared with the bubbling method, the efficiency is increased by 46.1 times when n=128. Through the CCS online simulation debugging window and the breakpoint observation, the Hill sorting method takes about 0.5ms, while the bubbling method takes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com