Method for manufacturing organic semiconductor/ferroelectric composite resistance-variable film through temperature-controllable spin coating

A technology of organic semiconductors and composite films, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve the problems of increased leakage of devices, rough surface of composite films, weakened resistance characteristics of devices, etc. The effect of low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

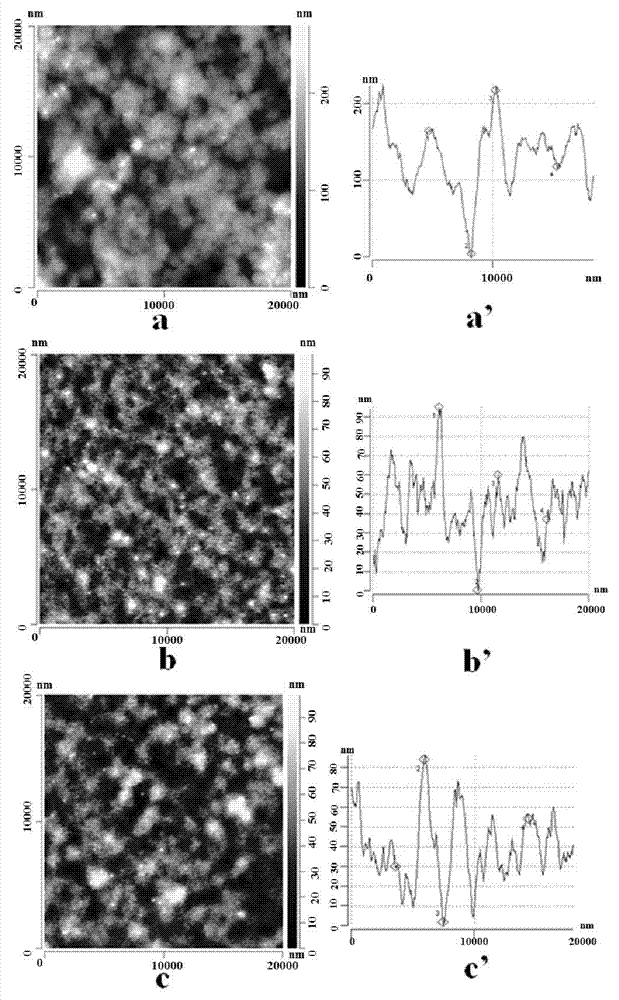

[0017] This embodiment illustrates that the adjustment of the roughness of the composite structure thin film is realized by adjusting the temperature of the spin coating environment. Proceed as follows:

[0018] 1) Prepare 10ml of tetrahydrofuran solution of P(VDF-TrFE) ferroelectric polymer with a mass concentration of 3.2%.

[0019] 2) Add P3HT to the above solution to prepare a mixed solution with a ratio of P3HT to P(VDF-TrFE) of 1:10.

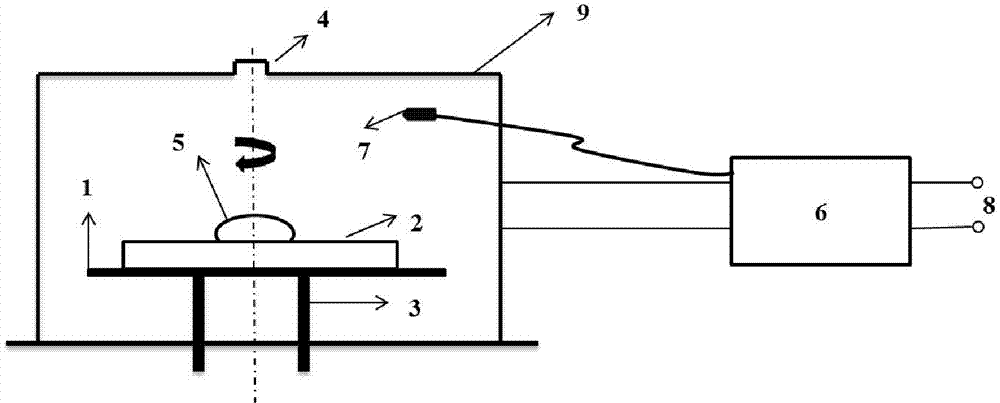

[0020] 3) At a specific ambient temperature, drop the mixed solution onto a clean glass slide in a temperature control device, and spin-coat at a speed of 700rpm to form a film.

[0021] 4) A total of 3 composite film samples were prepared, and the spin coating ambient temperatures were 20°C, 50°C and 70°C, respectively.

[0022] 5) Observe the surface morphology and roughness characteristics of the formed organic semiconductor / ferroelectric composite film with an atomic force microscope, and determine the influence of spin coating tempe...

Embodiment 2

[0025] This example illustrates the regulation and control of the spin-coating ambient temperature on the resistive properties of the organic semiconductor / ferroelectric composite thin film. Proceed as follows:

[0026] 1) A sandwich structure of metal / organic composite film / metal is prepared on a glass sheet, and the electrode is a silver electrode with a cross structure, and the electrode area is 0.2mm×0.1mm.

[0027] 2) The preparation method of the organic semiconductor / ferroelectric composite structure film is the same as that in Example 1, and the temperatures during spin coating are 20°C and 50°C, respectively.

[0028] 3) Conduct electrical tests to determine the resistance switching characteristics of the device obtained under different ambient temperatures.

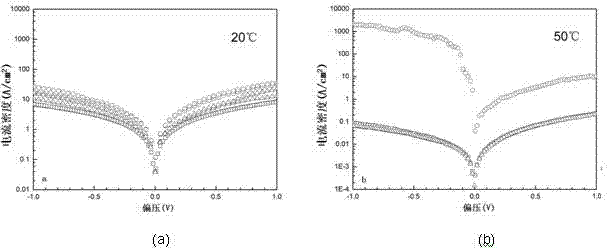

[0029] Typical results are attached image 3 shown. image 3 a shows the current-voltage (I-V) characteristic curve of the device with a spin-coating temperature of 20°C. The curve has a symmetrical structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com