Method for cultivating nucleus pearls

A cultivation method and pearl technology, applied in the cultivation field of nucleated pearls, can solve the problems of low survival rate, dim luster and poor quality of nucleated pearls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment relates to a method for cultivating nucleated pearls, said method comprising the steps of:

[0030] Step 1, take the bead nucleus, put it into the first treatment solution, soak and incubate for 2 hours;

[0031] Step 2, taking the small cell pieces of the edge membrane of the second half of the mussel body, soaking in the second treatment solution and culturing for 3 hours;

[0032] Step 3: Attach the small pieces of cells to the bead nucleus, then implant them into the mussel, and cultivate them for 2 years to form nucleated pearls;

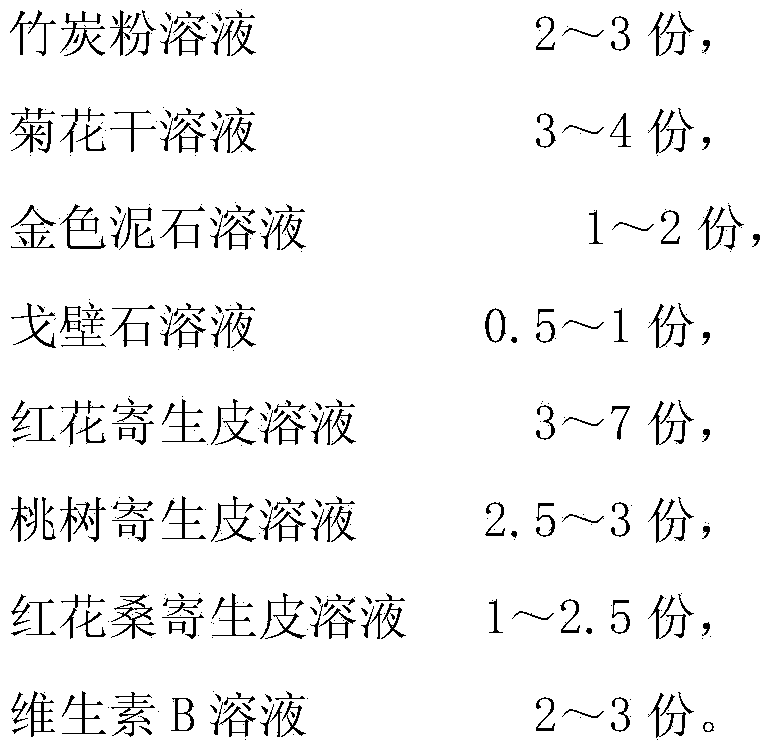

[0033] The first treatment liquid involved in this embodiment includes the following components in parts by weight:

[0034]

[0035] The bamboo charcoal powder solution adopted in the present embodiment refers to the bamboo charcoal mixed with pure water in a mass ratio of 1:3 after being pulverized, and filtered to obtain the solution. 1:2 mixing, filtering, and the obtained solution. The golden mudstone sol...

Embodiment 2

[0046] The present embodiment relates to a method for cultivating nucleated pearls, said method comprising the steps of:

[0047] Step 1, take the bead nucleus, put it into the first treatment solution, soak and incubate for 5 hours;

[0048] Step 2, taking the small cell pieces of the edge membrane of the second half of the mussel body, soaking in the second treatment solution and culturing for 5 hours;

[0049] Step 3: Attach the small pieces of cells to the bead core, then implant them into the mussels, and cultivate them for 4 years to form nucleated pearls;

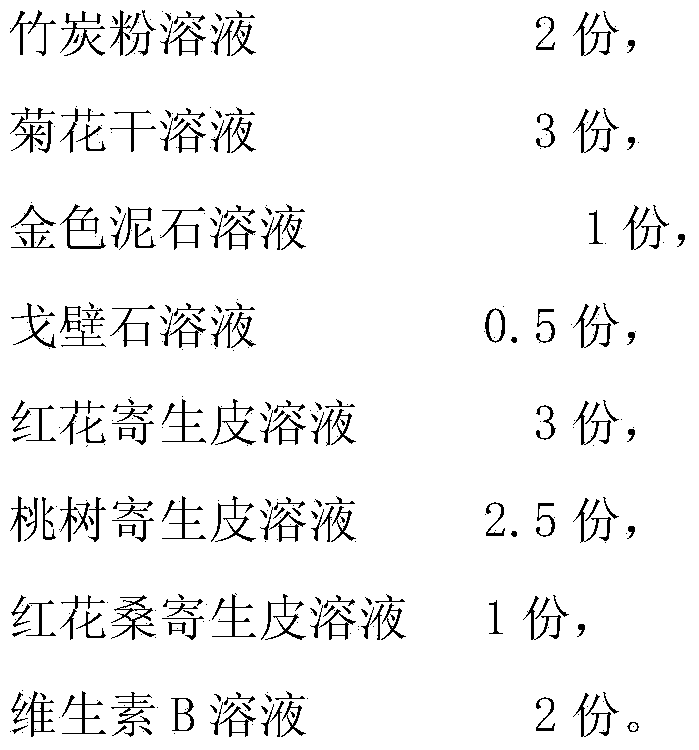

[0050] The first treatment liquid involved in this embodiment includes the following components in parts by weight:

[0051]

[0052] The bamboo charcoal powder solution adopted in the present embodiment refers to the bamboo charcoal mixed with pure water in a mass ratio of 1:3 after being pulverized, and filtered to obtain the solution. 1:2 mixing, filtering, and the obtained solution. The golden mudstone solut...

Embodiment 3

[0056] The present embodiment relates to a method for cultivating nucleated pearls, said method comprising the steps of:

[0057] Step 1, take the bead nucleus, put it into the first treatment solution, soak and incubate for 2.5 hours;

[0058] Step 2, taking the small cell pieces of the edge membrane of the second half of the mussel body, soaking in the second treatment solution and culturing for 4 hours;

[0059] Step 3: Attach the small pieces of cells to the bead core, then implant them into the mussels, and cultivate them for 3 years to form nucleated pearls;

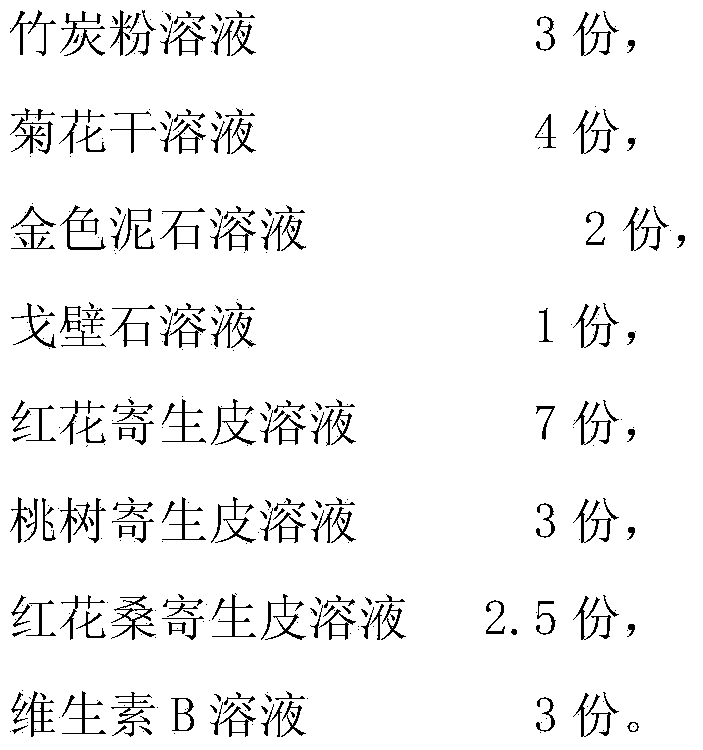

[0060] The first treatment liquid involved in this embodiment includes the following components in parts by weight:

[0061]

[0062] The bamboo charcoal powder solution adopted in the present embodiment refers to the bamboo charcoal mixed with pure water in a mass ratio of 1:3 after being pulverized, and filtered to obtain the solution. 1:2 mixing, filtering, and the obtained solution. The golden mudstone sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com