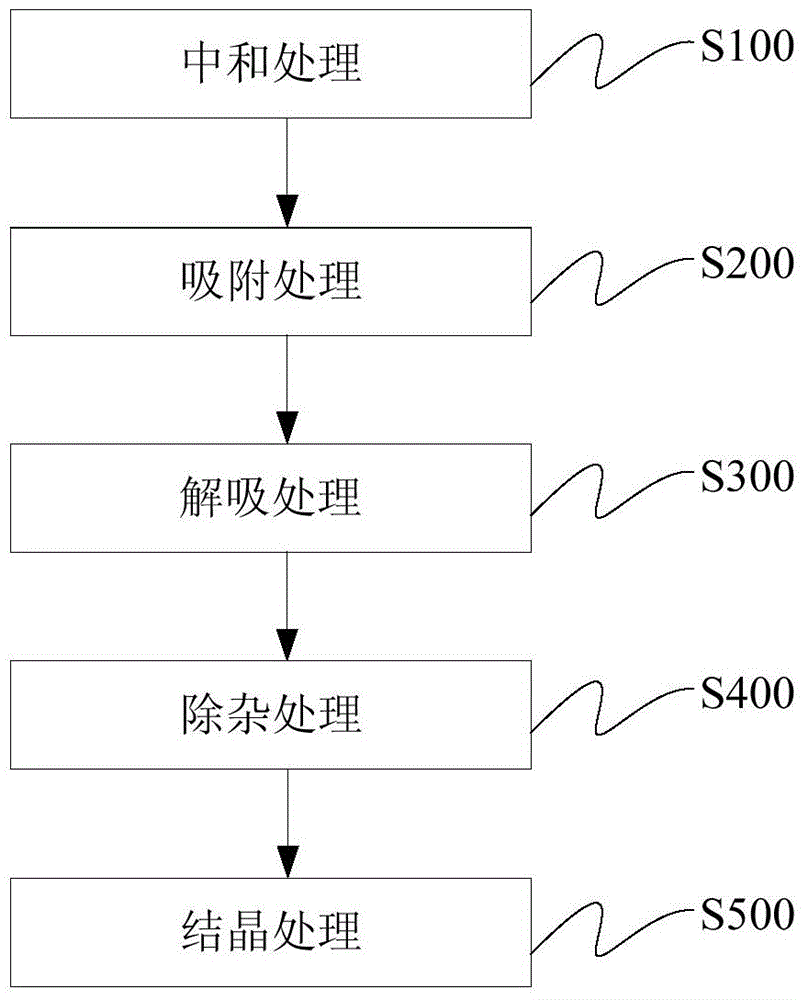

Method for preparing ammonium paratungstate by ion exchange method

A technology for preparing ammonium paratungstate and ion exchange method is applied in the field of preparing ammonium paratungstate by ion exchange method, which can solve the problems of low processing capacity of strong basic resin, large amount of waste water and large volume of processing solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

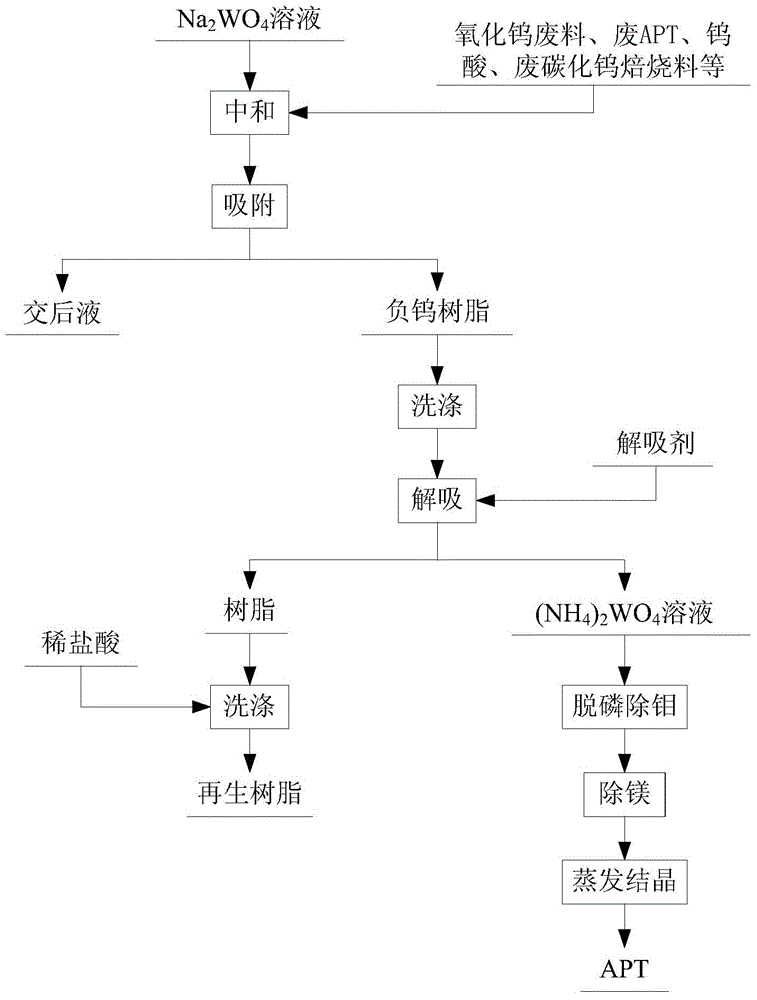

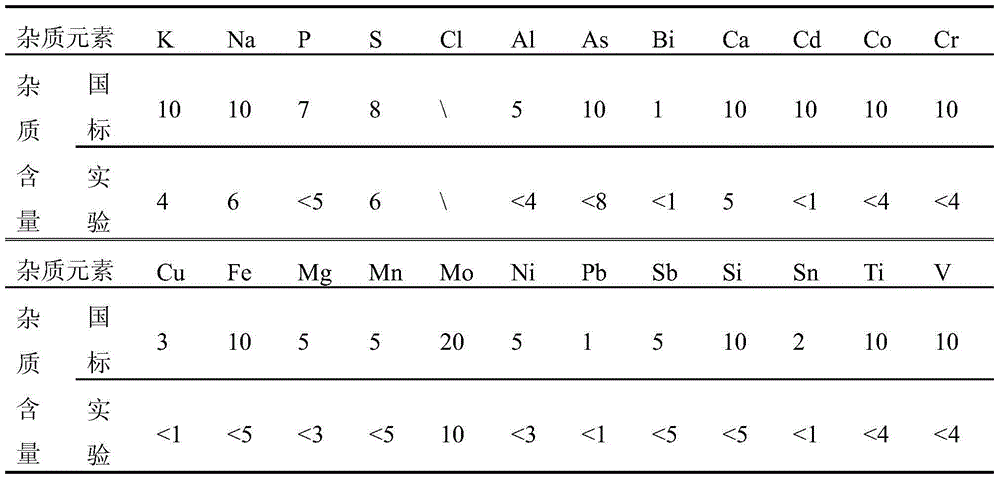

[0060] refer to figure 2 , take 200ml of concentrated sodium tungstate feed solution obtained by alkali decomposition of tungsten concentrate (WO 3 Concentration greater than 100g / L), add 30g of tungsten oxide waste under stirring conditions, heat and boil for neutralization, and filter when the pH reaches 8-9. Dilute the neutralized feed solution to a pre-delivery solution with a tungsten trioxide concentration of about 60g / L. At a linear speed of 2 cm / min, the pre-exchange solution was passed through an ion exchange column filled with 100 g of 312 resin for adsorption exchange until leakage. Use concentrated ammonia water for desorption, and control the desorption rate to 1cm / min. The desorption liquid with higher concentration of tungsten in the front section (the desorption liquid collected before the Baume degree drops to 13Be) is 150ml of desorption peak liquid, and the desorption liquid with lower tungsten concentration in the later stage (the desorption liquid colle...

Embodiment 2

[0065] refer to figure 2 , take 500ml of concentrated sodium tungstate feed solution obtained by alkali decomposition of tungsten concentrate (WO 3 Concentration greater than 100g / L), add 175g of crude tungstic acid under stirring conditions, heat and boil for neutralization, and filter when the pH reaches 8-9. Dilute the neutralized feed solution to a pre-delivery solution with a tungsten trioxide concentration of about 60g / L. At a linear speed of 2 cm / min, the pre-exchange solution was passed through an ion-exchange column equipped with 200 g of 640 resin for adsorption and exchange until leakage. Use ammonium chloride + ammonia water (Cl ion concentration 150-160g / L, ammonia water 2.5mol / L) for desorption, and control the desorption rate to 1cm / min. The desorption solution with higher concentration of tungsten in the front section (the desorption solution collected before the Baume degree drops to 13Be) is 289ml of desorption peak solution, and the desorption solution wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com