Hafnium carbide nanowire-toughened ceramic coating layer of surface of carbon/carbon composites and preparation method thereof

A carbon composite material and nanowire toughening technology, which is applied in the field of hafnium carbide nanowire toughening ceramic coating and preparation on the surface of carbon/carbon composite material, can solve the problem that the coating is not dense enough, the toughening effect is limited, and the coating is reduced. Anti-oxidation performance and other issues, to achieve the effect of uniform crystal particle size, reduced cracking tendency, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) After polishing the C / C composite material with a size of 10mm×10mm×10mm with sandpaper of No. 400, No. 800 and No. 1000 in sequence, it was ultrasonically cleaned with absolute ethanol for 1 hour, and the ultrasonic power was set to 90W. Dry in an oven at °C for later use.

[0045] 2) Configure Ni(NO) with a concentration of 0.2mol / L 3 ) 2 weak. Put the cleaned C / C composite material into the solution and soak for 3 hours, then take it out and dry it in an oven at 80°C for later use.

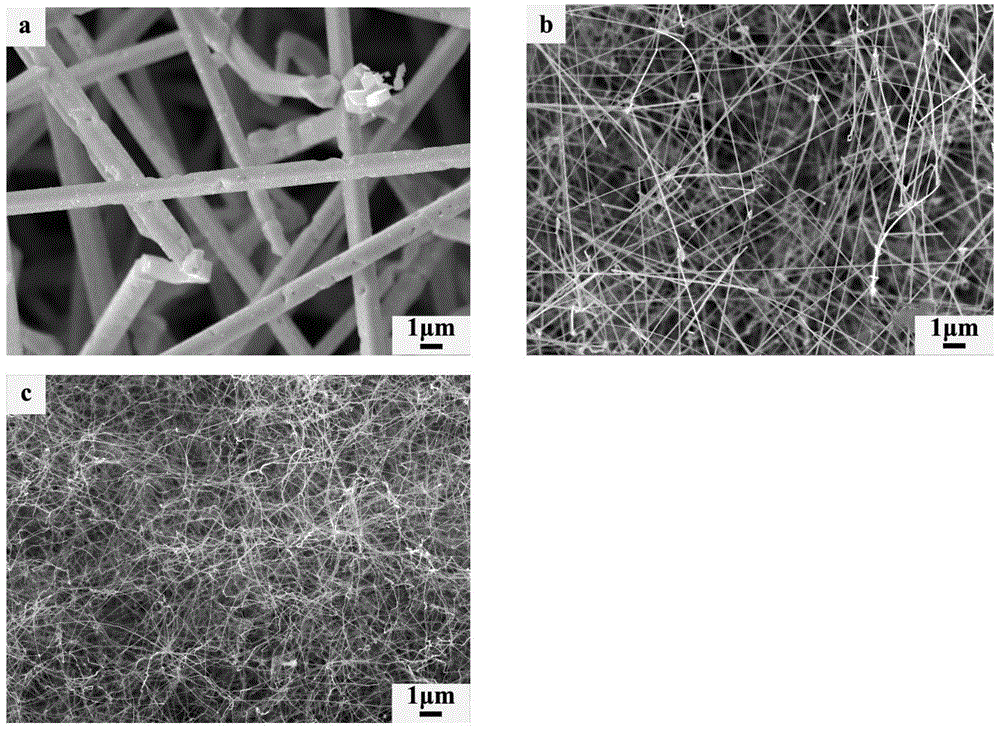

[0046] 3) Preparation of HfC nanowires by chemical vapor deposition (CVD) process, the specific method is as follows:

[0047] In step 2), the surface is attached with Ni(NO 3 ) 2 The C / C matrix is suspended in the high temperature zone of the vertical resistance furnace, and 50g of HfCl is weighed 4 The powder is placed in a quartz crucible in a low temperature area, the resistance furnace is evacuated to 2kPa, and H 2 As a protective gas, its flow rate is controlled at 1000...

Embodiment 2

[0052] 1) After polishing the C / C composite material with a size of 10mm×10mm×10mm with sandpaper of No. 400, No. 800 and No. 1000 in sequence, it was ultrasonically cleaned with absolute ethanol for 1 hour, and the ultrasonic power was set to 90W. Dry in an oven at °C for later use.

[0053] 2) Configure Ni(NO) with a concentration of 0.5mol / L 3 ) 2 weak. Put the cleaned C / C composite material into the solution and soak for 3 hours, then take it out and dry it in an oven at 80°C for later use.

[0054] 3) Preparation of HfC nanowires by chemical vapor deposition (CVD) process, the specific method is as follows:

[0055] In step 2), the surface is attached with Ni(NO 3 ) 2 The C / C matrix is suspended in the high temperature zone of the vertical resistance furnace, and 50g of HfCl is weighed 4 The powder is placed in a quartz crucible in a low temperature area, the resistance furnace is evacuated to 2kPa, and H 2 As a protective gas, its flow rate is controlled at 2000...

Embodiment 3

[0061] 1) After polishing the C / C composite material with a size of 10mm×10mm×10mm with sandpaper of No. 400, No. 800 and No. 1000 in sequence, it was ultrasonically cleaned with absolute ethanol for 1 hour, and the ultrasonic power was set to 90W. Dry in an oven at °C for later use.

[0062] 2) Configure Ni(NO) with a concentration of 1.0mol / L 3 ) 2 weak. Put the cleaned C / C composite material into the solution and soak for 3 hours, then take it out and dry it in an oven at 80°C for later use.

[0063] 3) Preparation of HfC nanowires by chemical vapor deposition (CVD) process, the specific method is as follows:

[0064] In step 2), the surface is attached with Ni(NO 3 ) 2 The C / C matrix is suspended in the high temperature zone of the vertical resistance furnace, and 50g of HfCl is weighed 4 The powder is placed in a quartz crucible in a low temperature area, the resistance furnace is evacuated to 2kPa, and H 2 As a protective gas, its flow rate is controlled at 3000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com