Method and system for fast targeted batch screening of biodiesel microalgae

A biodiesel, batch technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high product price, high processing cost, low algal autotrophic culture density, etc. Harm to the human body, avoid cross-contamination, improve the effect of targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1. Experimental method

[0071] 1) Sample processing

[0072] 40 samples of acidic wastewater containing algae (pH=3.0-6.5) were collected from coal-fired power plants, cement plants, and smelters near industrial flue gases in Hunan, Shaanxi, Gansu, and Inner Mongolia, etc., which have been in operation for more than 30 years. Water samples were stored in a refrigerator at 4°C.

[0073] Transfer 100ml of the water sample containing algae collected for enrichment culture, the culture temperature is 28°C, the light intensity is 7500lux, the ventilation rate is 0.33vvm, and CO2 with a volume concentration of 15% is passed through. 2 As a screening pressure, the incubation time was 14 days.

[0074] Cannot tolerate 15% CO through the above enrichment culture 2 Microalgae are eliminated or become vulnerable populations, which can tolerate 15% CO 2 The microalgae are enriched and become the dominant population, and the enriched water sample is obtained.

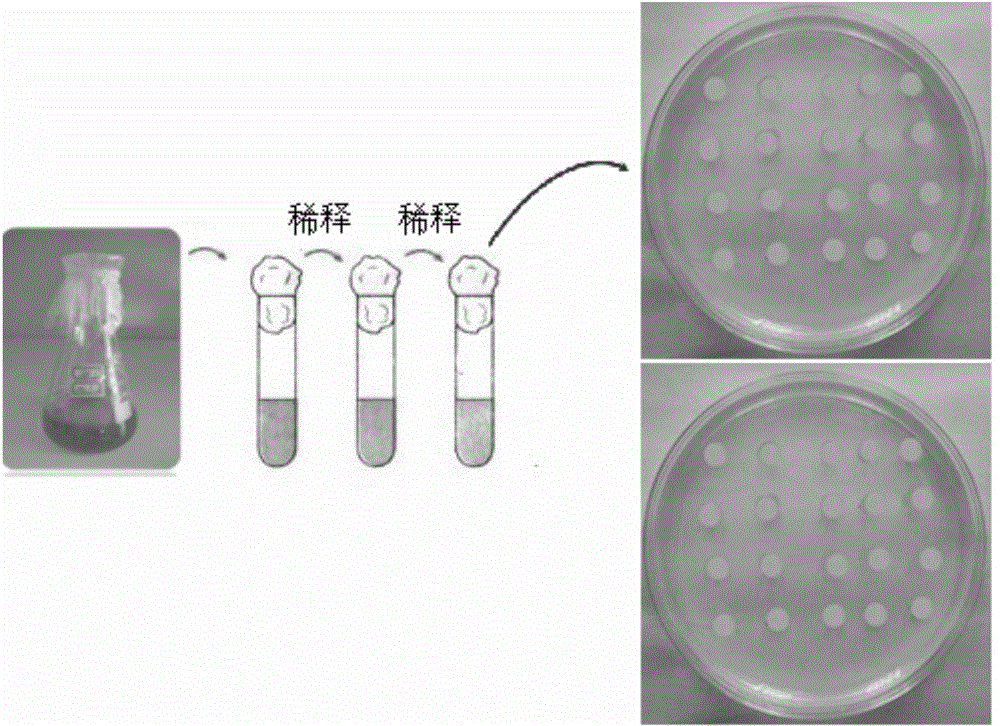

[0075] Prepare ...

Embodiment 2

[0082] 1. Experimental method

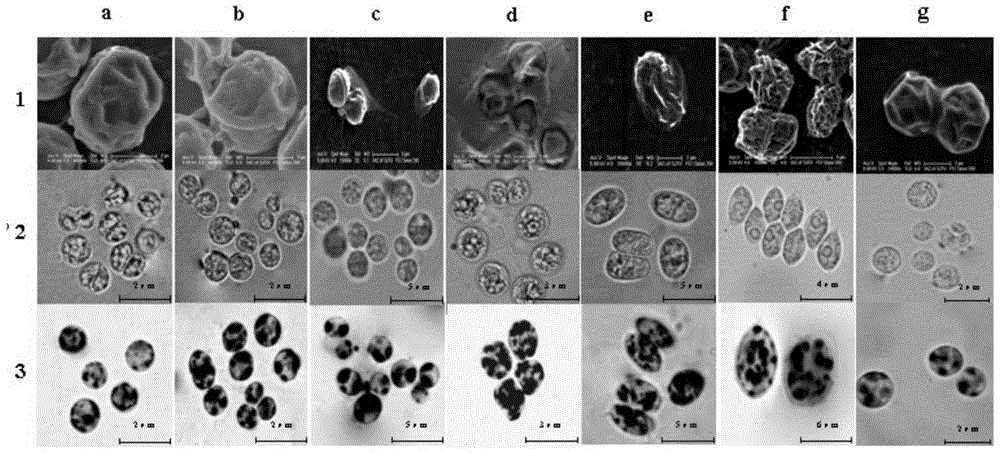

[0083] Select any four of the six strains of microalgae cells screened in Example 1 to cultivate, and detect the content of oil in the microalgae cells, the specific method is as follows:

[0084] 1.1 Algae strain a

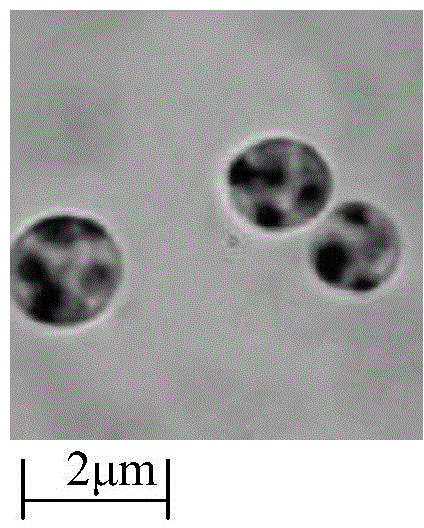

[0085] Pick up on solid plates under sterile conditions image 3 The single algae from the source shown in a (the deposit number is CCTCC M2013608, the date of deposit: November 27, 2013; the name of the depository unit: China Center for Type Culture Collection; the abbreviation of the depository unit: CCTCC) fell into the container containing 30ml of sterile culture solution. In a 100ml Erlenmeyer flask, it was cultured statically in a light culture rack at a temperature of 28°C, a light intensity of 7500 lux, a light-to-dark ratio of 12:12, and a culture time of 12 days. It grew to the end of the index to obtain seed liquid.

[0086] Prepare 500mL of BG-11 medium, and insert it into the expanded cell culture medium according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com