Material for sewage treatment, as well as preparation method and applications thereof

A technology for sewage treatment and mixing materials, applied in the fields of condensed matter physics and material science, to achieve the effect of saving energy consumption for smelting, good sewage treatment function, and good glass forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to another aspect of the present invention, there is also provided a method for preparing a high-entropy metallic glass for sewage treatment, including the following steps: Step S1, according to the above-mentioned components of the material for sewage treatment, that is, the high-entropy metal The chemical formula of the glass is batched to obtain a mixed material; step S2, melting the mixed material to obtain a master alloy; step S3, cooling the master alloy and preparing a high-entropy metallic glass strip; and step S4, pulverizing the high-entropy metallic glass strip to obtain a Materials for sewage treatment, namely high-entropy metallic glass powder. The preparation method provided by the invention has high speed, high efficiency, simple preparation and low overall cost.

[0037] Specifically, in step S2, an induction furnace is used to melt the mixed material. Preferably, the melting temperature may be 450-550° C., and the melting time may be 10-30 se...

Embodiment 1

[0041] Preparation of high-entropy metallic glass powder Sr 25 Ca 25 Mg 25 Zn 20 Cu 5

[0042] The five components of strontium and calcium with a purity of 99wt% of the raw materials and magnesium, zinc and copper with a purity of 99.9wt% are evenly mixed in a molar ratio of 25:25:25:20:5, and put into the quartz tube of the induction furnace. Under the protection of argon atmosphere, the temperature was raised to 450° C. and kept for 30 seconds for melting to obtain the master alloy.

[0043] Using the belt throwing device of the induction furnace, the melt of the master alloy is sprayed to the surface of the copper roller rotating at a high speed of 30 m / s to cool, and a high-entropy metallic glass strip with an average thickness of 15 microns is obtained.

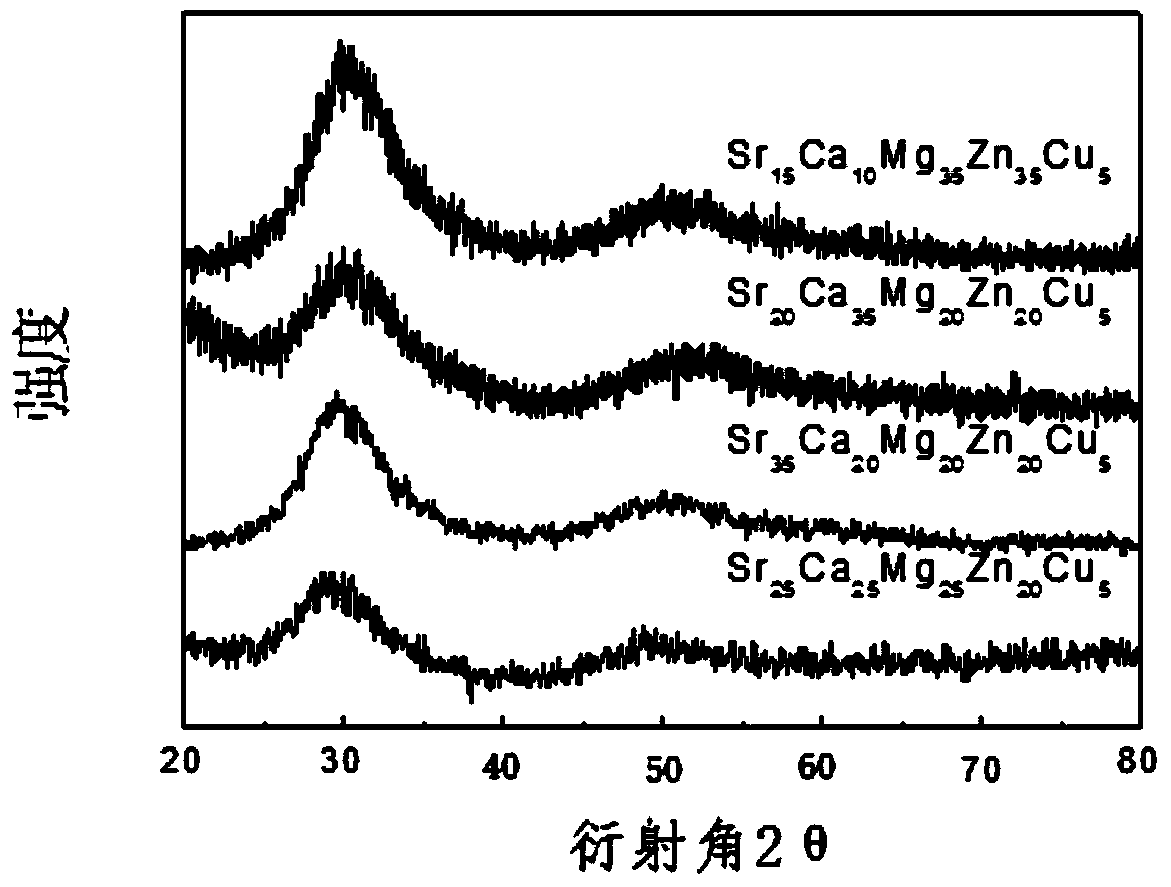

[0044] High-entropy metallic glass strips were ground by high-energy ball milling for 1 hour to obtain high-entropy metal powder Sr with a particle size of 20 μm. 25 Ca 25 Mg 25 Zn 20 Cu 5 . The X-ray diffrac...

Embodiment 2~43

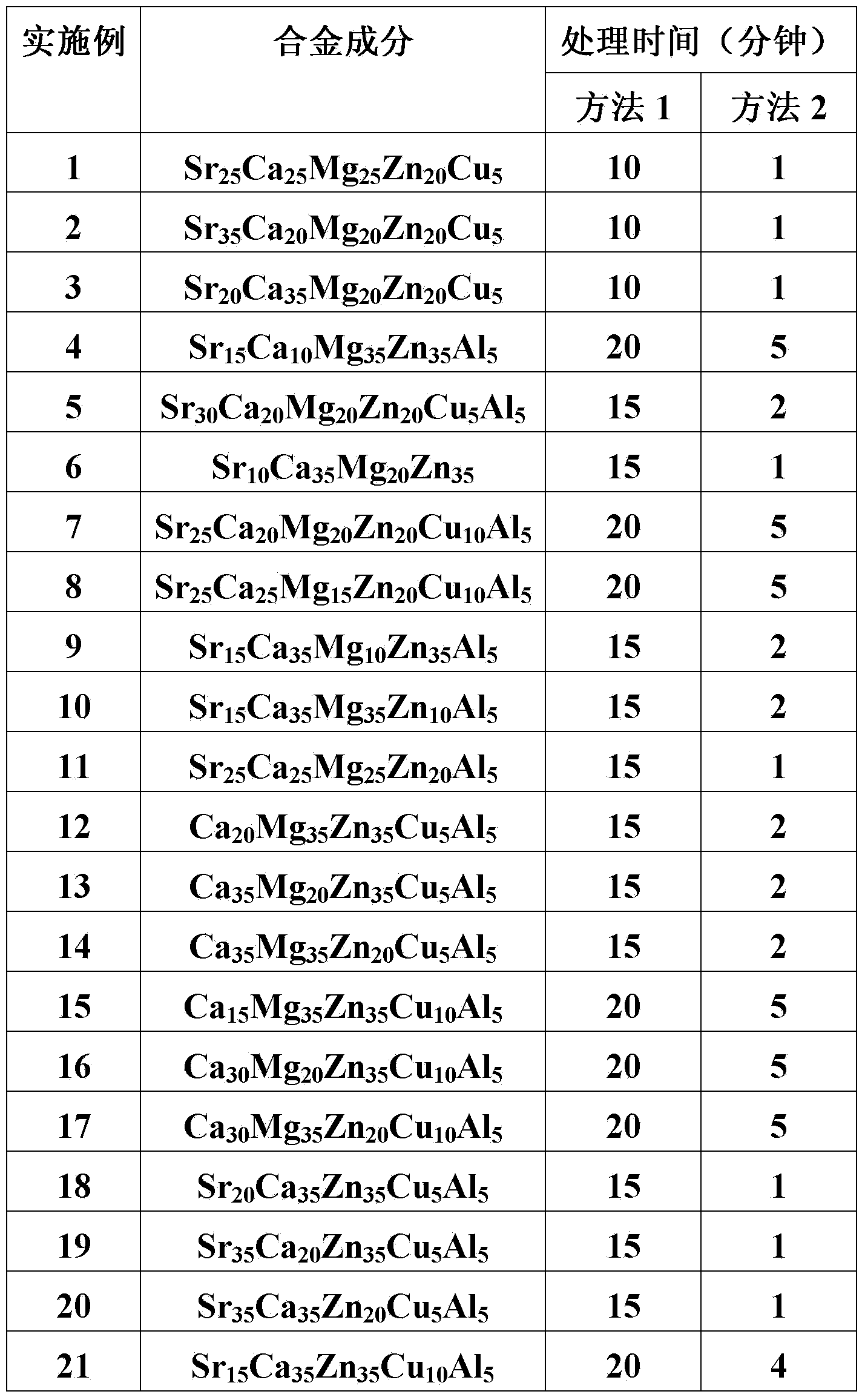

[0049] According to the method of Example 1, various proportioning high-entropy metallic glass powders were prepared. The method of using the high-entropy metallic glass powders was the same as in Example 1. The composition and sewage treatment time of each proportioning high-entropy metallic glass powders were listed in the table. 1 in. The high-entropy metallic glass powders prepared in Examples 2 to 43 all have broad diffuse peaks without obvious crystallization peaks, indicating that the metal powder samples prepared by the method of the present invention are all amorphous.

[0050] Table 1. Composition of high-entropy metallic glass powders and wastewater treatment time

[0051]

[0052]

[0053] It can be seen from the data in Table 1 that the high-entropy metallic glass powder prepared by the present invention is applied in sewage treatment, especially in industrial wastewater containing azo dyes, and the industrial wastewater can be cleaned within 10 to 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com