Piezoelectric power generation device using pulse vibration of vehicle tail gas to generate power and power generating method

A technology of pulse vibration and piezoelectric power generation, applied in machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve problems such as higher costs, complex energy transmission routes, and complex exhaust system structures, and save resources. , The effect of reducing exhaust noise and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

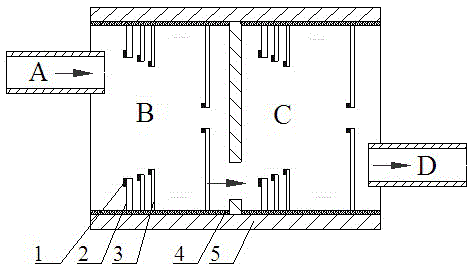

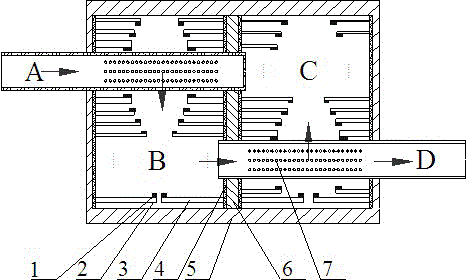

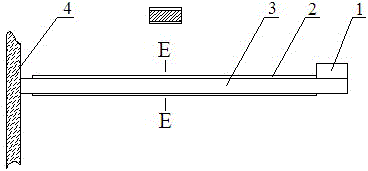

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] The exhaust gas produced by the engine 1 enters the exhaust gas catalytic conversion device 5 through the exhaust manifold 2 and the connecting flange 3. The oxygen sensor 4 can measure the oxygen content in the exhaust gas and transmit the information to the vehicle. The catalytic conversion device 5 is used to catalyze the harmful substances in the exhaust gas to undergo chemical reactions, so as to reduce the emission of harmful gases. The exhaust gas after catalytic treatment passes through the flexible joint for preliminary noise reduction, and the oxygen content, pressure and temperature signals of the exhaust gas after preliminary noise reduction are measured by the oxygen sensor 7, pressure sensor 8 and temperature sensor 17, and transmitted to the vehicle. The exhaust gas enters the muffler 13 through the connecting flange 12, and finally enters the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com