Method for detecting barium and zinc in zinc-barium liquid compound stabilizer

A compound stabilizer and liquid barium-zinc technology, which is applied in the detection field, can solve the problems of large error, unfavorable test method popularization and high price, and achieve the effect of low cost, easy promotion and application, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Weigh 1.0000 g of liquid barium-zinc composite stabilizer sample, add 10 ml of No. 120 solvent gasoline to fully dissolve, dilute to 100 ml with absolute ethanol, shake well, and set aside.

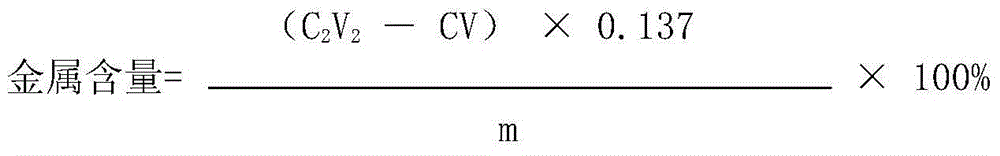

[0047] (2) Pipette two parts of each 50ml of the solution prepared in step (1), add 20ml of 10% ammonium fluoride aqueous solution to one of them, then add 10ml of ammonia-ammonium chloride buffer solution with pH=10, add chrome black T Use 5 drops of indicator, titrate with EDTA standard titration solution until the solution turns pure blue as the titration end point, record the volume V of EDTA standard titration solution consumed 1 ; Another part does not add ammonium fluoride, all the other processes are the same, record the volume V of EDTA standard titration solution consumed 2 ; Calculated according to formula 1 and formula 2, the results are shown in Table 1.

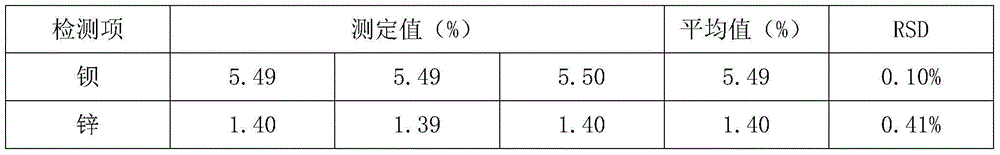

[0048] Table 1 Barium, zinc content measurement results

[0049]

Embodiment 2

[0051] Methodological investigation:

[0052] (1) Specificity

[0053] The metal effective components in the liquid barium-zinc organic compound stabilizer of the present invention are only barium and zinc, and solvent gasoline and absolute ethanol are used as solvents in the experimental method, so the added solvent and medicine in the whole experimental process have no other obvious interference of impurity ions. Ammonium fluoride is used as a masking agent, and the pH is controlled at 10 to mask barium ions, so that the content of each metal component can be detected. By investigating the addition amount of ammonium fluoride, determine the suitable range of the addition amount of ammonium fluoride.

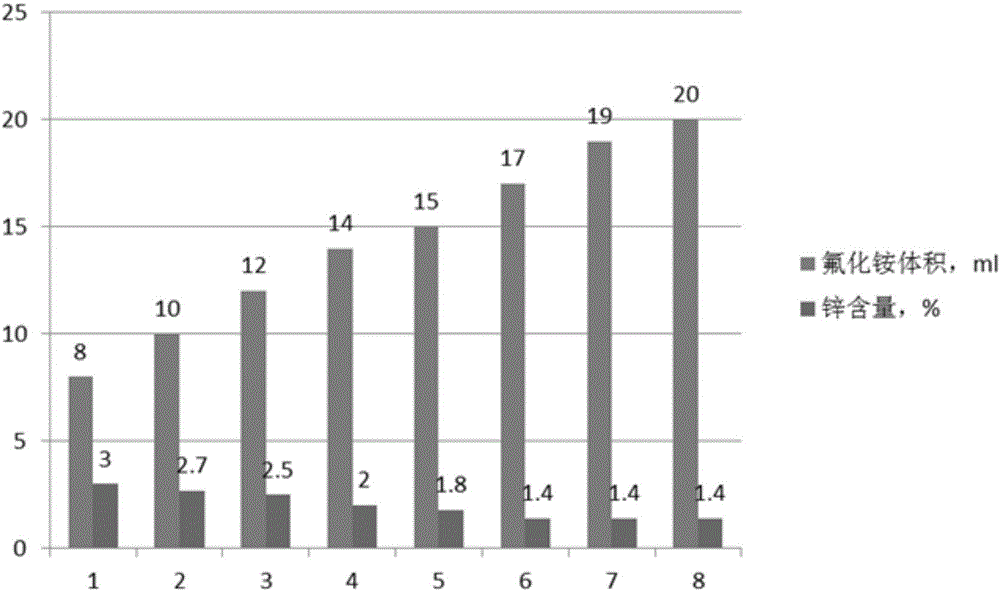

[0054] see results figure 1 , it can be seen from the figure that when the amount of ammonium fluoride added is too small, there are interfering ions participating in the reaction, and the detection result of zinc content is too high. In this experiment, the fluoride ions in ...

Embodiment 3

[0060] Comparative Test:

[0061] Get the same batch of liquid barium-zinc composite stabilizer samples, adopt atomic absorption spectrophotometry and the method of the present invention to measure respectively, the results are shown in Table 2.

[0062] Table 2 Comparison of the results of different assay methods

[0063]

[0064] Can find out by comparison, method of the present invention is close to atomic absorption spectrophotometry measurement result, therefore, method of the present invention can be used for measuring the content of barium and zinc in the liquid barium-zinc composite stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com