A uniform light spot surface scanning device for a laser cleaning machine

A technology of laser cleaning and surface scanning, which is applied in the direction of optics, optical components, instruments, etc., can solve the problems of missing cleaning or over cleaning, difficult correction of optical system and mechanical mechanism, distortion of spot position, etc., to achieve small diameter, laser cleaning Increased speed and low optical power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

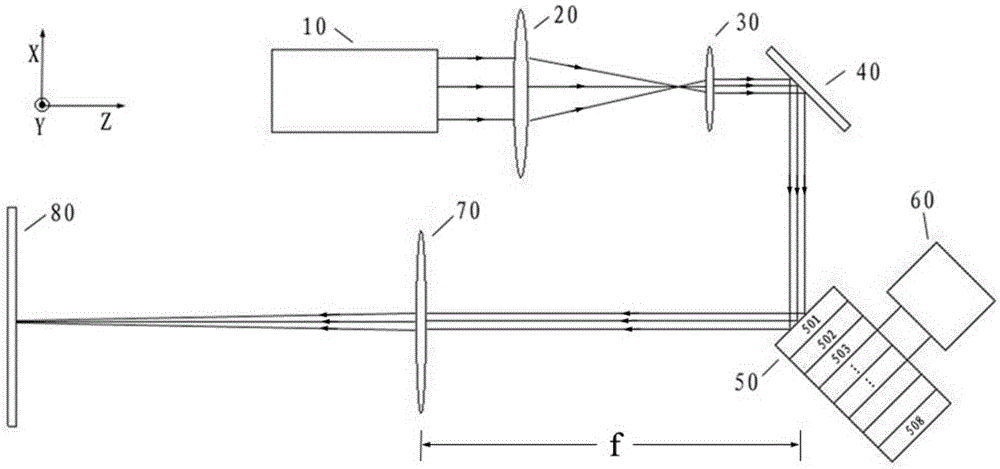

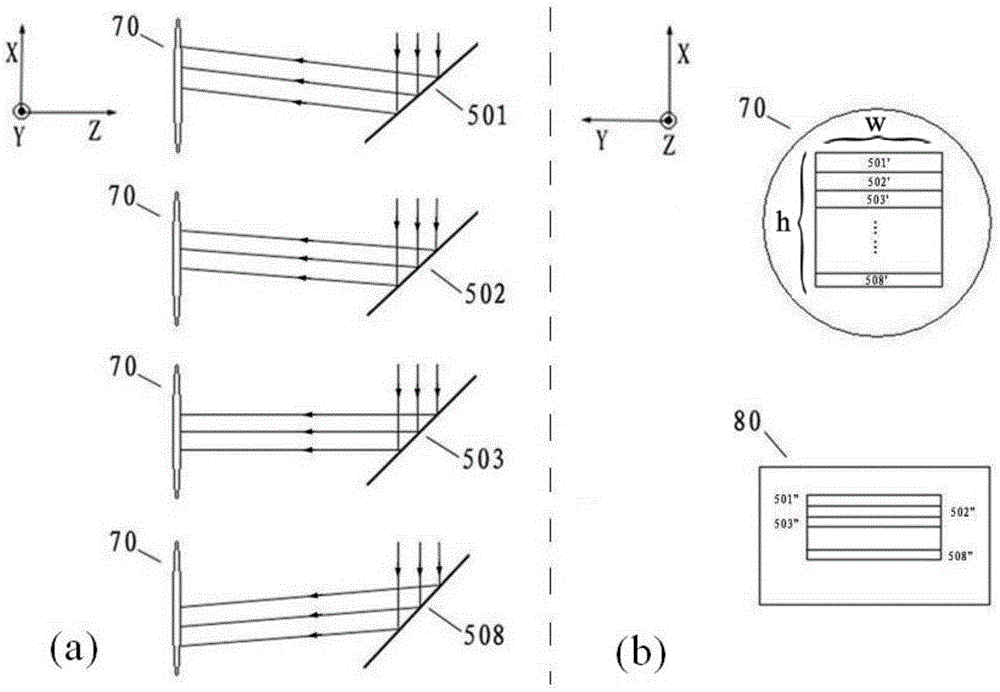

[0040] A specific example of the present invention is described below in conjunction with accompanying drawing:

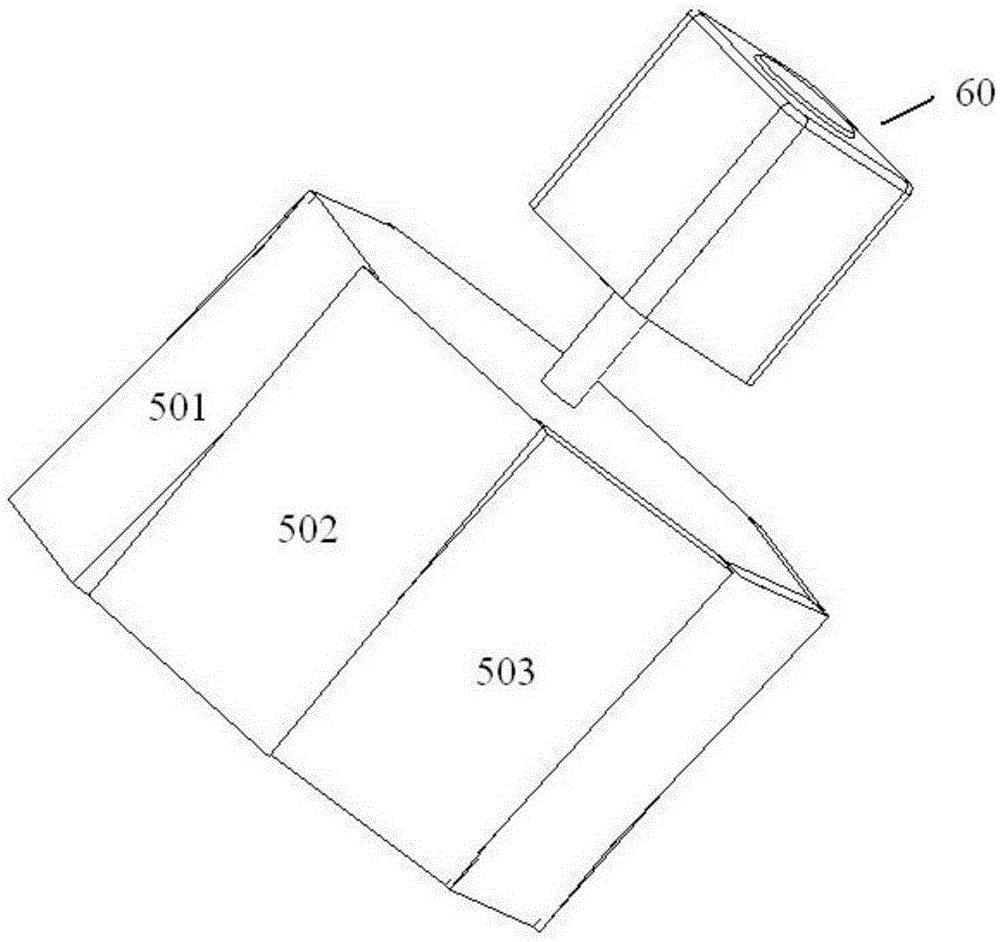

[0041] This example is designed for an infrared laser with a circular spot shape (diameter 8mm), a Gaussian distribution of light energy, and a center wavelength of 1064nm. It is suitable for laser cleaning and laser surface treatment. This example is composed of a laser output module 10 , an aspheric lens 20 , an aspheric lens 30 , a reflector 40 , a progressive rotating polygonal mirror 50 , a driving motor 60 and a collimating focusing lens 70 .

[0042] The components and features contained in the device are: the working laser source is fiber laser, YAG laser or CO2 laser, the laser output module 10 emits continuous or pulsed laser, the energy is non-uniformly distributed (typically Gaussian), and the laser wavelength range is 0.532 μm ~10.64μm, the output power is less than 1000W; the material of the aspheric lens 20 and 30 is quartz, CaF or ZnSe, the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com