Preparation method of high molecular polymer micro-fluidic chip

A high molecular polymer, microfluidic chip technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc. problems, to achieve the effect of being conducive to mass production, realizing functional diversification, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

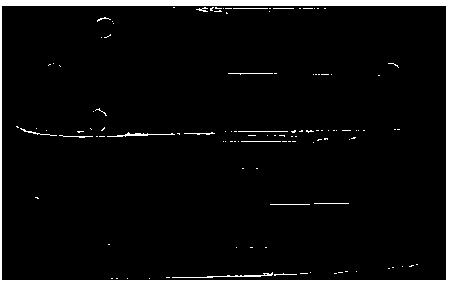

[0044] Such as figure 1 As shown, the classic cross-shaped chip electrophoresis chip (upper) and the cross-shaped chip with added separation channels (lower), the channel width is 100 microns, and the depth is 80 microns.

[0045] Its preparation process steps are:

[0046] 1) Use numerical control software to design the channel of the microfluidic chip, obtain the corresponding engraving path, and write the engraving code for engraving;

[0047] 2) Import the engraving code into the software that controls the engraving machine, and engrave the polymer material to be produced;

[0048] 3) After engraving, according to different requirements, the chip is sealed to obtain a functional microfluidic chip.

[0049] In the step 2), when engraving the polymer material, the size of the engraving knife is 100 μm, fix the polymer material to be produced on the CNC engraving machine platform, select the appropriate initial engraving coordinates, set The rotation speed is 5000r / min, the...

Embodiment 2

[0052] Such as image 3 As shown, the chip of the microreactor, the chip includes two sample inlets, one product outlet, the channel width is 100 microns, the depth is 80 microns, the effective reaction distance is 54 cm, and the chip size is only 1.8 cm × 7 cm.

[0053] The manufacturing process is basically the same as that of Example 1, except that: in the step 2), when engraving the polymer material, the size of the engraving knife is 100 μm, select the appropriate initial engraving coordinates, and set the rotation speed to 7000r / min, the speed is 50mm / min, the coolant is a mixture of ethanol and ethylene glycol (volume ratio 1:1), and the cycle starts.

Embodiment 3

[0055] Such as Figure 4 As shown, the schematic diagrams of several types of chips used to characterize the effect of solution mixing, to prove that the chips made by the engraving machine have no obstacles to the mixing of solutions, and the channel width is designed to be 200 μm and the depth is 80 μm.

[0056] The production process is basically the same as that of Example 1, except that in the step 2), when engraving the polymer material, the size of the engraving knife is 200 μm, and the polymer material to be produced is fixed on the engraving On the machine platform, select the appropriate initial engraving coordinates, set the rotation speed to 5000r / min, the speed to 50mm / min, add a mixture of ethanol and ethylene glycol (volume ratio 1:1) as the cooling liquid, and the cycle starts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com