Automatic manufacturing device of flange plate

A technology for manufacturing devices and active power, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of high logistics cost, high labor intensity, long process flow, etc., to save investment in plant construction and reduce equipment Quantity, the effect of reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

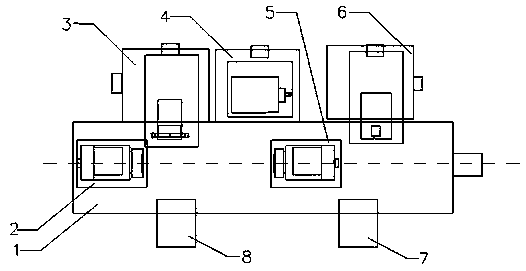

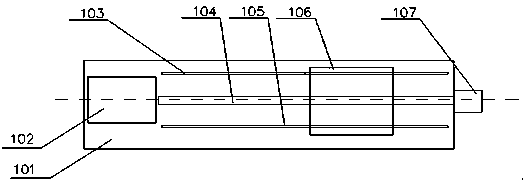

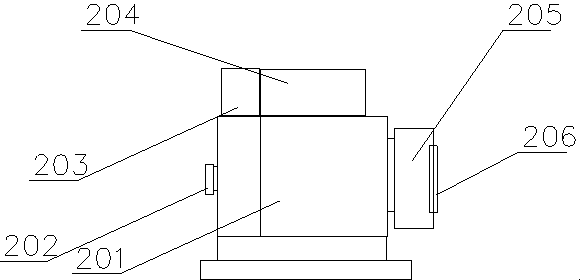

[0055] Such as figure 1 As shown, an automatic manufacturing device for a flange includes a main bed unit 1, a first turning power unit 2, a turning feed unit 3, a drilling unit 4, a second turning power unit 5, a marking unit 6, a lower Material unit 7, material loading unit 8 and control system.

[0056]The first turning power unit 2 and the second turning power unit 5 are arranged on the same straight line of the main bed unit 1, the first turning power unit 2 is fixed on one end of the main bed unit 1, and the second turning power unit 5 can be moved along The straight line slides on the guide rail on the main bed unit 1, the turning feed unit 3, the drilling unit 4 and the marking unit 6 are sequentially arranged on the side of the main bed unit 1, and the feeding unit 8 and the unloading unit 7 are arranged on the The other side of the main bed unit. The first turning power unit 2 receives the workpiece to be processed (from the feeding unit 8) and provides the active ...

Embodiment 2

[0066] In this embodiment, the marking unit 6 and the feeding unit 8 can be simplified to form a simplified version of the flange manufacturing station to complete all mechanical processing. The simplified version of the flange manufacturing station manually loads the workpiece to reduce costs. The flange plate manufacturing station without the identification unit 6 is beneficial to reduce the complexity of the control system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com