Composite fluorescent transparent ceramic used for white-light LED and adopting garnet structure

A technology of fluorescent ceramics and composite ceramics, which is applied in the field of high-efficiency white light LED composite transparent fluorescent ceramic structures, can solve the problems of reduced luminous efficiency, poor thermal stability, loss of light output, etc., and achieves high color rendering index, high quantum efficiency, high light effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

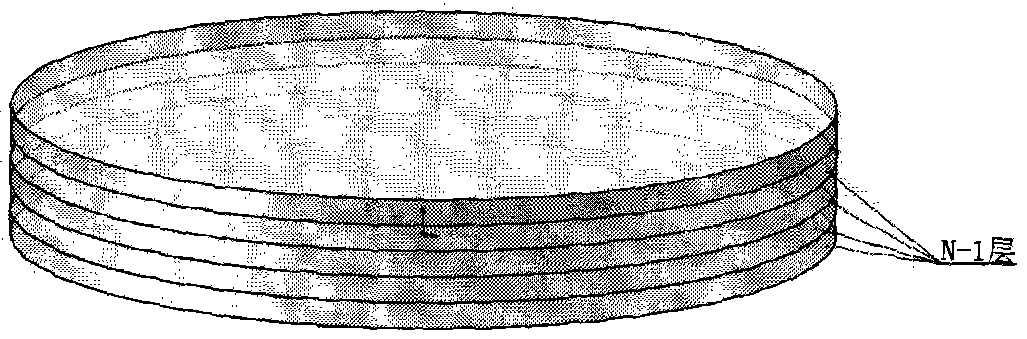

[0026] Press (Ce 0.1% Y 99.9% ) 3 Al 5 o 12 Chemical composition weighing α-Al 2 o 3 Powder, Y 2 o 3 Powder, CeO 2 Powder raw materials, according to (Ce 0.1% SM 0.2% Y 99.7% ) 3 Al 5 o 12 Chemical composition weighing CeO 2 Powder, α-Al 2 o 3 Powder, Y 2 o 3 Powder, Sm 2 o 3 Powder. Add 0.1200g of TEOS and 0.5400g of PVB into the high-purity agate ball milling tank for the two types of mixed powder, add 80g of high-purity agate balls, 12g of absolute ethanol, and pour them into the defoaming machine after ball milling for 20 hours. 20 min, and then cast by a casting machine to obtain a 600-micron casting layer. The prepared (Ce 0.1% SM 0.2% Y 99.7% ) 3 Al 5 o 12 and (Ce 0.1% Y 99.9% ) 3 Al 5 o 12 Ten layers of casting layers are stacked to form a composite ceramic casting layer of 20 layers, put into a dry pressing mold at 110°C for 10 hours, press unidirectionally with a pressure axis of 20Mpa to form a non-layered integral composite ceramic ...

Embodiment 2

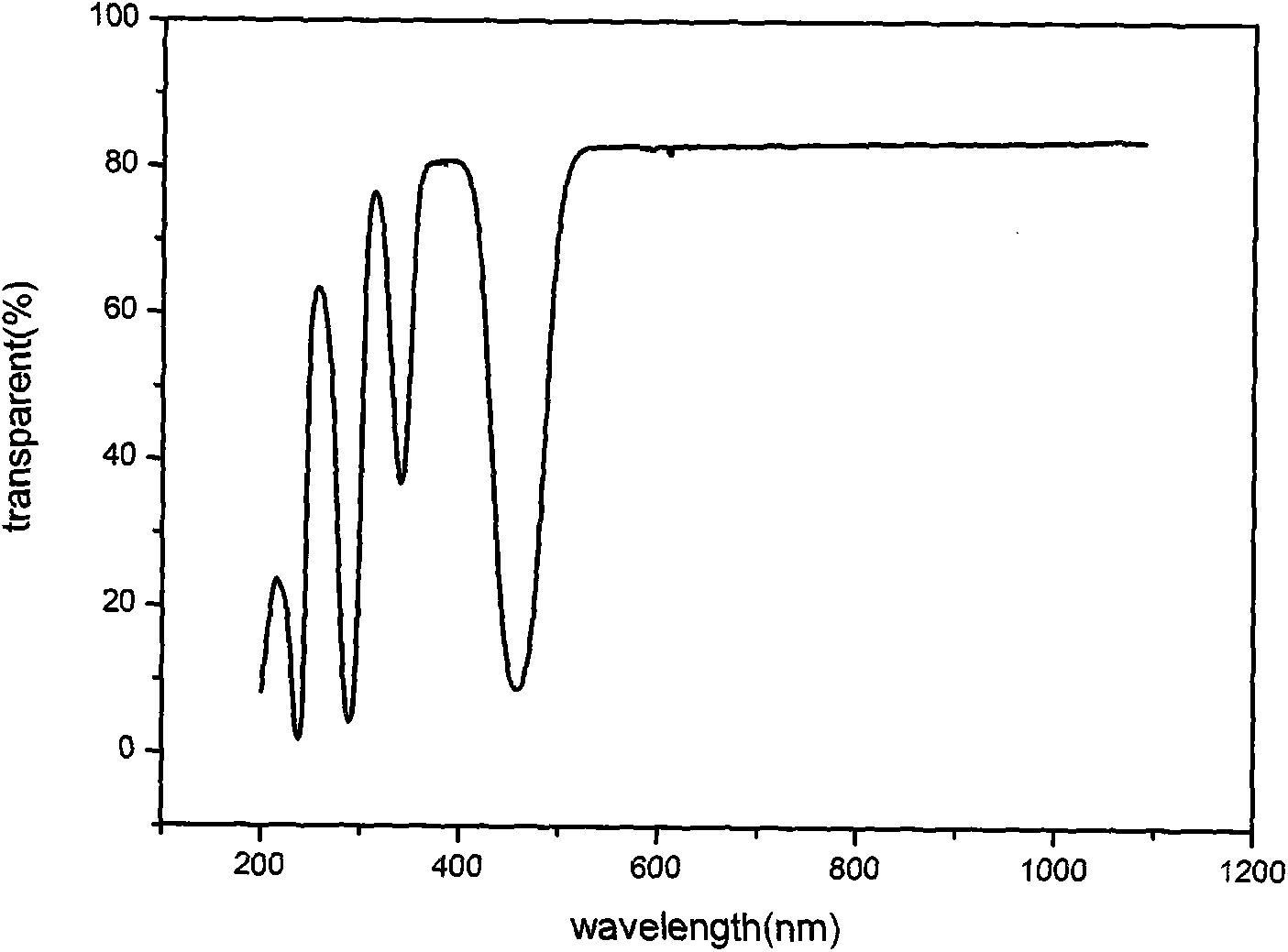

[0033] Take (Ce 0.1% Y 99.9% ) 3 al 5 o 12 Cast layer six layers, (Ce 0.1% SM 0.2% Y 99.7% ) 3 al 5 o 12 Part of the six layers, after polishing, the thickness of the sample obtained is 1.30mm, where (Ce 0.1% Y 99.9% ) 3 al 5 o 12 Part thickness is 0.65mm, (Ce 0.1% SM 0.2% Y 99.7% ) 3 al 5 o 12 Part thickness is 0.65mm. Other conditions were the same as in Example 1 to obtain a composite transparent fluorescent ceramic with a visible light transmittance of 83.2%.

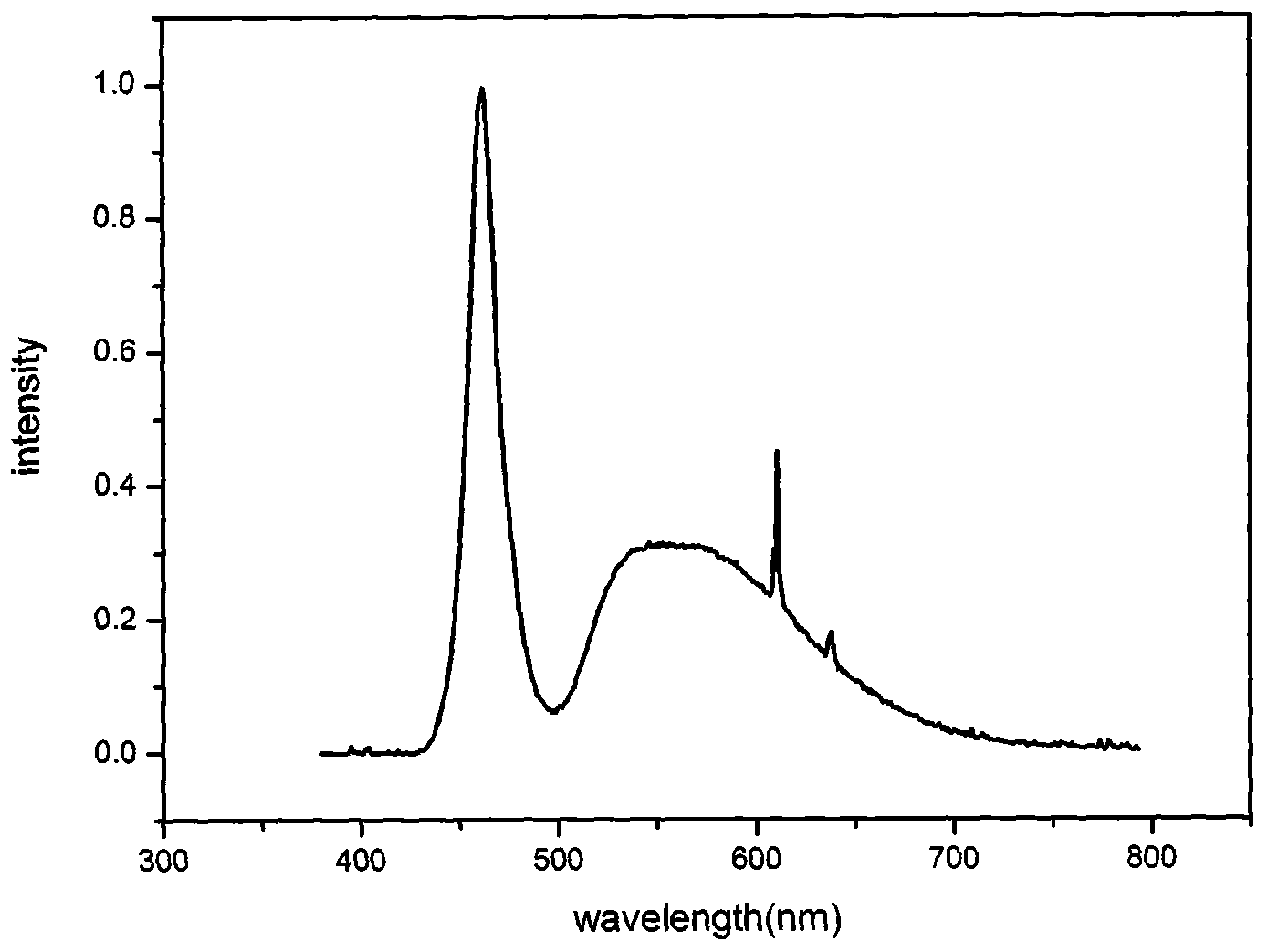

[0034] The transparent ceramic white light LED prepared in this example is driven by a 20mA constant current, and a 450nm blue light chip is excited to obtain a white light LED, and its performance indicators are as follows:

[0035] Light effect: 135lm / W

[0036] Quantum Efficiency: 95.2%

[0037] Color rendering index: 79

[0038] Color temperature: 5700K.

Embodiment 3

[0040] Press (Ce 0.1% Y 99.9% ) 3 al 5 o 12 Chemical composition weighing α-Al 2 o 3 Powder, Y 2 o 3 Powder, CeO 2 Powder raw materials, according to (Ce 0.1% Gd 5% Y 94.9% ) 3 al 5 o 12 Chemical composition weighing CeO 2 Powder, α-Al 2 o 3 Powder, Y 2 o 3 Powder, Gd 2 o 3 Powder. The sintering temperature was 1825° C., the holding time was 25 hours, and the other conditions were the same as in Example 2 to obtain a composite transparent fluorescent ceramic with a visible light transmittance of 82.7%.

[0041] The transparent ceramic white light LED prepared in this example is driven by a 20mA constant current, and a 450nm blue light chip is excited to obtain a white light LED, and its performance indicators are as follows:

[0042] Light effect: 134lm / W

[0043] Quantum Efficiency: 94.9%

[0044] Color rendering index: 80

[0045] Color temperature: 5600K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com