Production method of mesotrione

A production method, the technology of mesotrione, is applied in the production field of the new herbicide mesotrione, and achieves the effects of reducing production costs and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

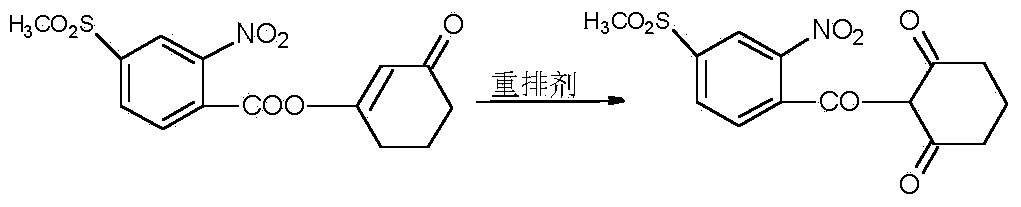

Method used

Image

Examples

Embodiment 1

[0025] Preparation of mesotrione: In a reaction flask, add 300g (0.88mol) 3-(2-nitro-4-thiamphenicol benzoyl chloride)-2-cyclohexen-1-one, 2500ml acetonitrile, 4.5 g (0.044mol) triethylamine, 30g potassium ferrocyanide (0.071mol), stirred and heated, the reaction temperature was 50°C, reacted for 15h, cooled, and filtered to obtain 31.8 grams of wet product translocation agent, and the filtrate was mixed with 2mol / Acidify with L hydrochloric acid to make the pH value 2-3, add 2500ml dichloromethane after desolventization to dissolve and separate the layers, separate the organic layer, wash twice with 5000ml water, desolventize the organic phase, and crystallize to obtain 264g mesotrione with a yield of 88 %.

Embodiment 2

[0027] Preparation of mesotrione: In a reaction flask, add 300g (0.88mol) 3-(2-nitro-4-thiamphenicol benzoyl chloride)-2-cyclohexen-1-one, 2500ml acetonitrile, 4.5 g (0.044mol) triethylamine, Example 1 filter out 31.8 grams of wet product potassium ferrocyanide recovered, stir and heat, the reaction temperature is at 50°C, react for 15h, cool, filter, acidify with 2mol / L hydrochloric acid, make The pH value is 2-3. After precipitation, 2500ml of dichloromethane is added to dissolve and separate the layers. The organic layer is separated and washed twice with 5000ml of water. The organic phase is precipitated and crystallized to obtain 255g of mesotrione with a yield of 85%.

Embodiment 3

[0029] The preparation of mesotrione: in reaction flask, add 300g (0.88mol) 3-(2-nitro-4-thiamphenicol benzoyl chloride)-2-cyclohexen-1-one, 2500ml dichloromethane , 150g (1.4mol) triethylamine, 30g potassium ferrocyanide (0.071mol), stir and heat, the reaction temperature is 10°C, react for 20h, cool, filter, acidify with hydrochloric acid, make the pH value 2-3, let stand Separate the layers, separate the organic layer, wash twice with 5000ml of water, desolventize the organic phase, and crystallize to obtain 240g of mesotrione, with a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com