Polymer and surfactant binary system for oil displacement, and oil displacement method

A technology of binary system and oil displacement method, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve problems such as poor oil displacement efficiency, increase hydrophilicity, high surface activity, and solve interfacial tension rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

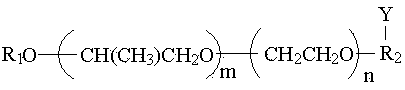

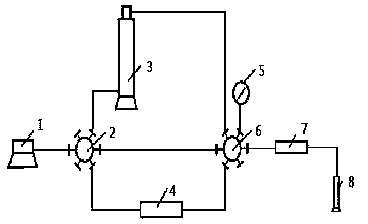

Method used

Image

Examples

Embodiment 1

[0043] (1) Octadecyl polyoxypropylene (m=3) polyoxyethylene (n=10) 45 parts of sodium ether hydroxypropanesulfonate, 10 parts of cetyl betaine, 50 parts of ethanol and 47 parts of tap water were added in sequence In a mixing container, raise the temperature to 80°C and stir for 3 hours, then distill off ethanol under reduced pressure to obtain the required composite surfactant, in which octadecyl polyoxypropylene (m=3) polyoxyethylene (n=10) ether hydroxyl The total content of sodium propanesulfonate and cetyl betaine accounts for 55.1% of the composite surfactant in terms of mass percentage.

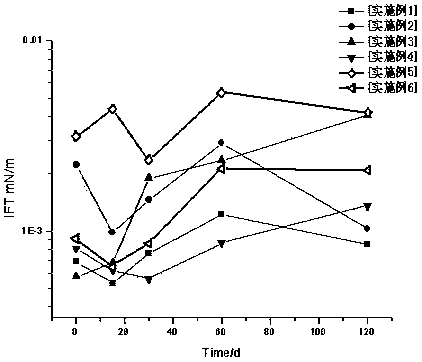

[0044] (2) Prepare the aqueous solution of composite surfactant and low molecular weight modified polyacrylamide (M=7 million) prepared in step (1) with Sha 7 formation water (TDS 15000mg / L) in Jiangsu Oilfield, stir for 3 hours, and then The two were mixed to obtain a homogeneous poly-surface binary system oil displacement agent. The viscosity of the system and the oil-water interfacia...

Embodiment 2

[0050] (1) 30 parts of nonylphenol polyoxypropylene (m=8) polyoxyethylene (n=6) potassium ether ethanesulfonate, 15 parts of cocamidopropyl betaine, 50 parts of methanol and 57 parts of deionized water Add to the mixing container in turn, raise the temperature to 50°C and stir for 3 hours, distill the methanol under reduced pressure to obtain the required composite surfactant, in which nonylphenol polyoxypropylene (m=8) polyoxyethylene (n=6) ether The total content of potassium ethanesulfonate and cocamidopropyl betaine accounted for 45.3% of the composite surfactant in terms of mass percentage.

[0051] (2) Prepare the aqueous solution of composite surfactant and low molecular weight modified polyacrylamide (M=9 million) prepared in step (1) with Sha 7 formation water (TDS 20000mg / L) in Jiangsu Oilfield, stir for 4 hours, and the rest are the same as [Example 1] (2), the results are shown in Table 2.

[0052] (3) Use 55°C as the oil displacement temperature, and the rest are...

Embodiment 3

[0057] (1) Behenyl polyoxypropylene (m=4) polyoxyethylene (n=2) 25 parts of sodium ether ethanesulfonate, 5 parts of cetyl betaine, 50 parts of isopropanol and 75 parts of tap water in order Add it into a mixing container, raise the temperature to 90°C and stir for 2 hours, distill off isopropanol under reduced pressure to obtain the required composite surfactant, in which behenyl polyoxypropylene (m=4) polyoxyethylene (n= 2) The total content of sodium ether ethanesulfonate and cetyl betaine accounted for 29.8% of the composite surfactant in terms of mass percentage.

[0058] (2) Prepare the aqueous solution of composite surfactant and low molecular weight modified polyacrylamide (M=5 million) prepared in step (1) with Sha 7 formation water (TDS 10000mg / L) in Jiangsu Oilfield, stir for 2 hours, and the rest are the same as [Example 1] (2), the results are shown in Table 3.

[0059] (3) Use 90°C as the oil displacement temperature, inject 0.2PV, and the rest are the same as [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com