Oil displacement method implemented by aid of viscous-elastic surfactants

A technology of surfactant and oil displacement method, which is applied in chemical instruments and methods, earthwork drilling, and drilling composition, etc. Critical micelle concentration, improved oil displacement efficiency, and increased surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

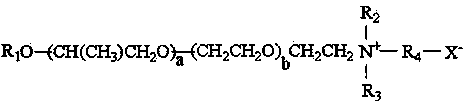

[0028] 1) In parts by mass, take nonylphenol polyoxypropylene polyoxyethylene ether betaine [a=8, b=2, R 2 =CH 3 , R 3 =CH 3 , R 4 =CH 2 CH(OH)CH 2 ,X - = SO 3 - ] 5 parts, sodium octadecyl polyoxypropylene polyoxyethylene ether hydroxypropane sulfonate [c=2,d=4, R 6 =CH 2 CH(OH)CH 2 ,Y=SO 3 Na] 1 part, 6 parts of ethanol and 6.5 parts of 2wt% sodium chloride aqueous solution were sequentially added to the reaction flask, the temperature was raised to 65°C and stirred for 3 hours, and the ethanol was removed by distillation under reduced pressure to obtain the desired viscoelastic surfactant. Add formation water from low-permeability reservoirs in Sha 7 Oilfield, Jiangsu (total salinity TDS is 20,000 mg / L), prepare 1.0wt% viscoelastic surfactant formation aqueous solution, dilute to different concentrations with water of the same salinity, and measure The viscosity of the system and its oil-water interfacial tension with the dehydrated crude oil in this block, the ...

Embodiment 2

[0033] 1) In parts by mass, tetradecyl polyoxypropylene polyoxyethylene ether betaine [a=4, b=8, R 2= CH 3 , R 3 = CH 3 , R 4 =CH 2 CH 2 ,X - = SO 3 - ] 20 parts, potassium nonylphenol polyoxypropylene polyoxyethylene ether ethanesulfonate [c=8,d=6, R 6 =CH 2 CH 2 ,Y=SO 3 K] 1 part, 20 parts of isopropanol and 25 parts of 5wt% sodium chloride aqueous solution were added to the reaction flask successively, the temperature was raised to 80°C and stirred for 3 hours, and the isopropanol was removed by distillation under reduced pressure to obtain the required viscoelastic surfactant . Same as [Example 1] 1) prepare 1.0wt% viscoelastic surfactant formation aqueous solution, measure oil-water interfacial tension and viscosity when different concentrations, the total salinity TDS of formation water used is 15000 mg / liter, the results are shown in Table 2 shown.

[0034] 2) Same as [Example 1] 2), except that the oil displacement temperature is 75°C, and the concentrati...

Embodiment 3

[0038] 1) In parts by mass, take dodecylphenol polyoxypropylene polyoxyethylene ether betaine [a=6, b=2, R 2= CH 2 CH 2 OH,R 3 =CH 2 CH 2 OH,R 4 =CH 2 CH 2 ,X - = SO 3 - ] 2 parts, sodium octadecyl polyoxypropylene polyoxyethylene ether hydroxypropane sulfonate [c=2,d=4, R 6 =CH 2 CH(OH)CH 2 ,Y=SO 3 Na] 1 part, 3 parts of isopropanol and 3.5 parts of deionized aqueous solution were sequentially added to the reaction flask, the temperature was raised to 80°C and stirred for 1 hour, and the isopropanol was removed by vacuum distillation to obtain the desired viscoelastic surfactant. Same as [Example 1] 1) prepare 1.0wt% viscoelastic surfactant formation aqueous solution, measure oil-water interfacial tension and viscosity at different concentrations, the results are shown in Table 3.

[0039] 2) Same as [Example 1] 2), except that the core permeability is 10.8×10 -3 μm 2 , and the results are shown in Table 7.

[0040] table 3

[0041] Concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas permeability | aaaaa | aaaaa |

| Total salinity | aaaaa | aaaaa |

| Core permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com