High-temperature energy-saving furnace

An energy-saving furnace and high-temperature technology, which is applied in the direction of household furnace/stove, household heating, heating fuel, etc., can solve the problems of high gas consumption, fuel loss, high degree of environmental pollution, etc., and achieve high combustion temperature, simple structure and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

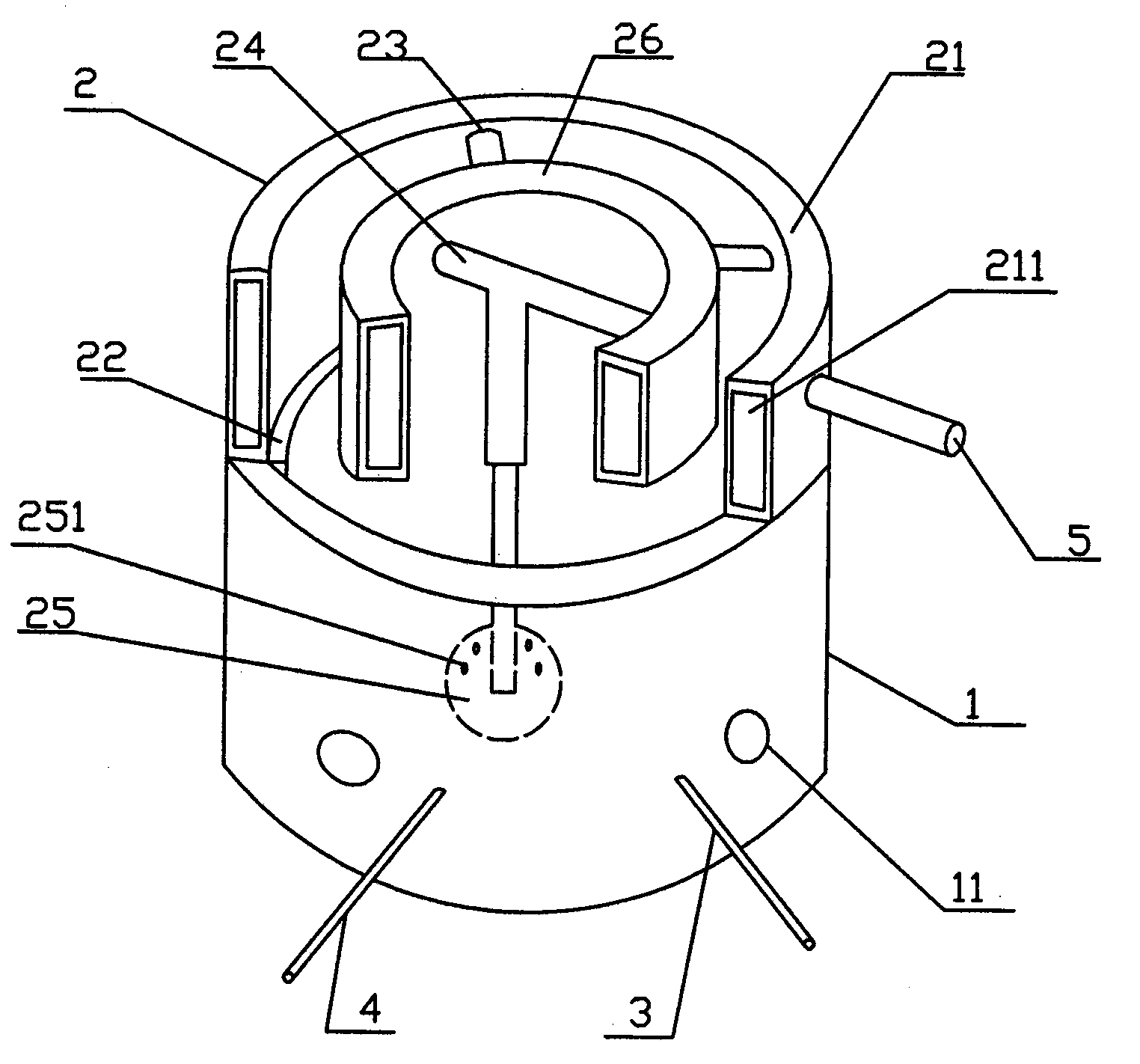

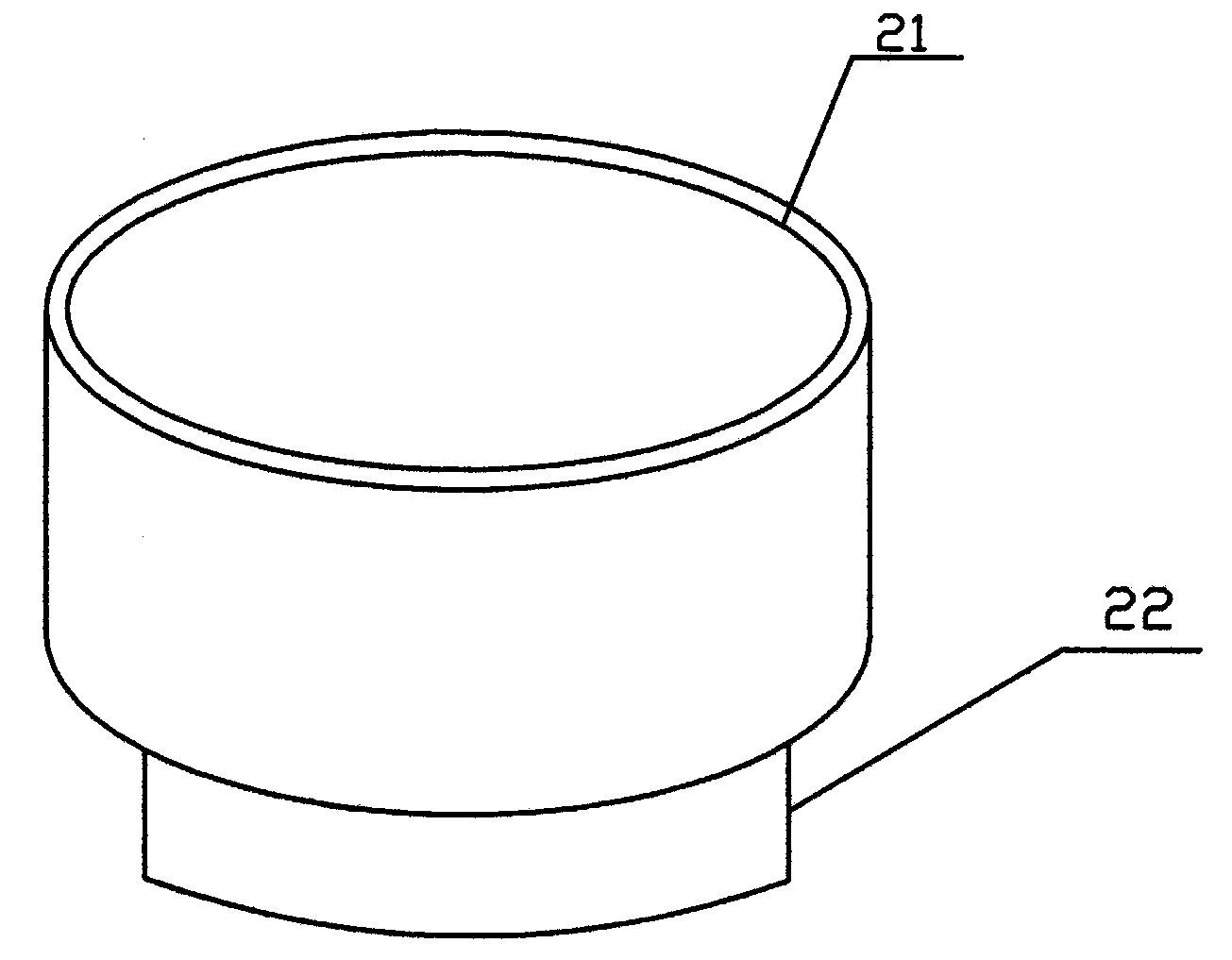

[0019] Such as figure 1 Shown, a kind of high-temperature energy-saving furnace, it comprises furnace base 1, furnace gall 2, ignition device 3, ignition oil inlet pipe 4, oil delivery pipe 5, furnace base 1 is a hollow cylindrical body, furnace base 1 wall body is provided with several Air vent 11, ignition device 3 and ignition oil inlet pipe 4 are installed on the wall body of furnace base 1 respectively, and the igniter of ignition device 3 and the oil outlet of oil inlet pipe 4 are arranged in furnace base 1, and igniter can be on the oil inlet pipe The oil liquid sprayed at the oil outlet is ignited; the furnace bladder 2 includes an outer bladder 21, a bladder seat 22, a fuel pipe 23, a three-way pipeline 24, a vaporization spheroid 25 and an inner tank 26, and the outer tank 21 and the inner tank 22 are both The annular interior is provided with the bile-shaped body of the hollow oil delivery chamber 211, and the diameter of the inner container is smaller than the diam...

Embodiment 2

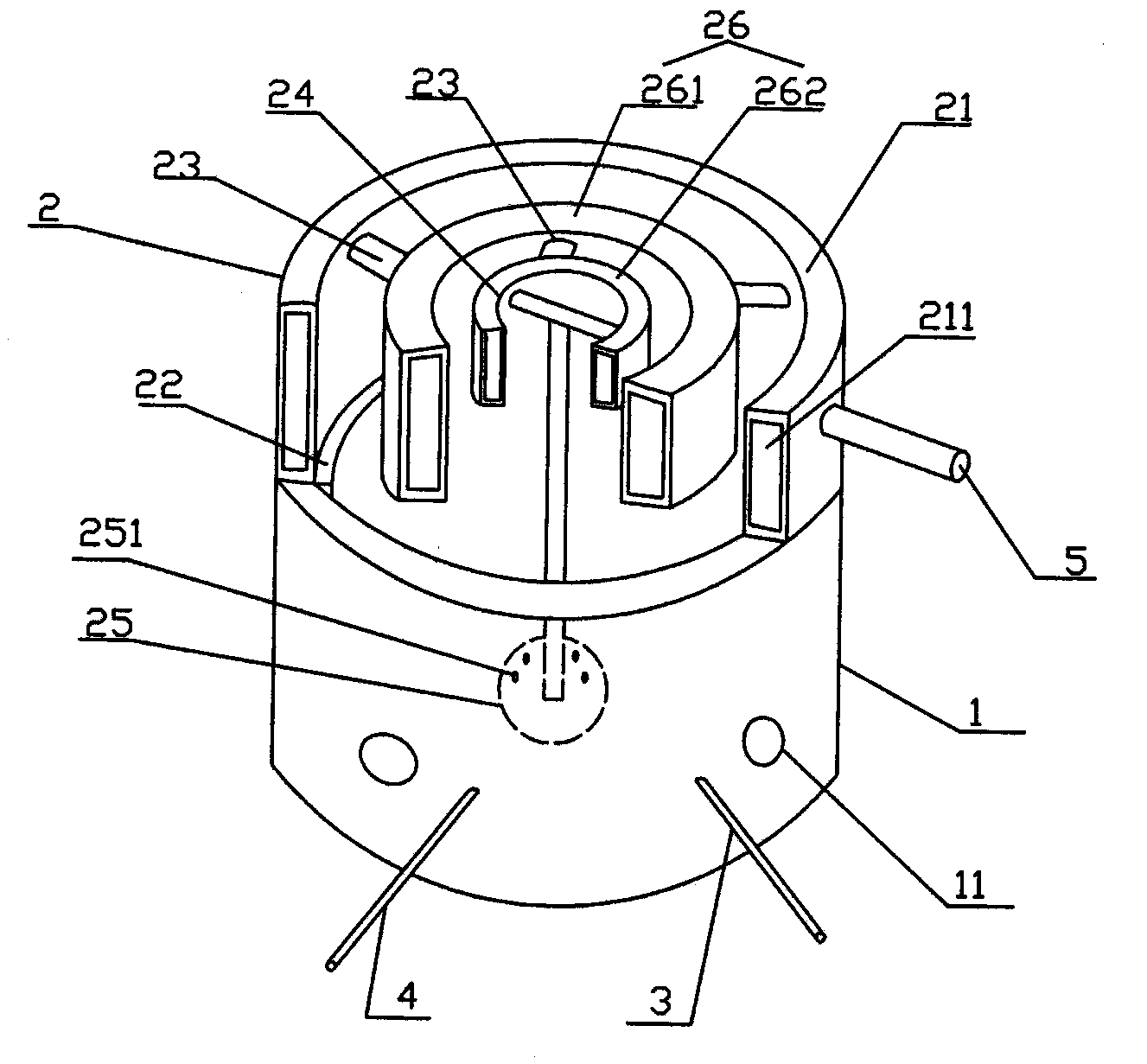

[0021] Such as figure 2 Shown, a kind of high-temperature energy-saving furnace, it comprises furnace base 1, furnace gall 2, ignition device 3, ignition oil inlet pipe 4, oil delivery pipe 5, furnace base 1 is a hollow cylindrical body, furnace base 1 wall body is provided with several Air vent 11, ignition device 3 and ignition oil inlet pipe 4 are installed on the wall body of furnace base 1 respectively, and the igniter of ignition device 3 and the oil outlet of oil inlet pipe 4 are arranged in furnace base 1, and igniter can be on the oil inlet pipe The oil liquid sprayed at the oil outlet is ignited; the furnace bladder 2 includes an outer bladder 21, a bladder seat 22, a fuel pipe 23, a three-way pipeline 24, a vaporization spheroid 25 and two inner tanks 26, and the outer tank 21 and the inner tank 22 are all It is a bile-shaped body with a hollow oil delivery chamber 211 inside the ring shape, and the diameter of the inner pot is smaller than that of the outer pot. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com