Graphene/polyaniline/stannic oxide composite material applied to supercapacitor and manufacturing method thereof

A technology of supercapacitor and composite material, applied in the field of graphene/polyaniline/tin oxide composite material and its preparation, can solve the problem of high specific capacitance, achieve the effect of increasing specific capacitance, broad application prospects and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of graphite oxide: Take flake graphite (1g), sodium nitrate (0.2g) and concentrated sulfuric acid (30ml) into a 1000ml beaker, add potassium permanganate (1g) while stirring with a stirrer, continue after adding Stir for 14h; then add deionized water (100ml) therein, and then add concentration of 30% hydrogen peroxide (10ml), at this moment, the suspension is yellow, and the solid is separated by filtration or centrifugation, and dried, namely It is graphite oxide, ready for use.

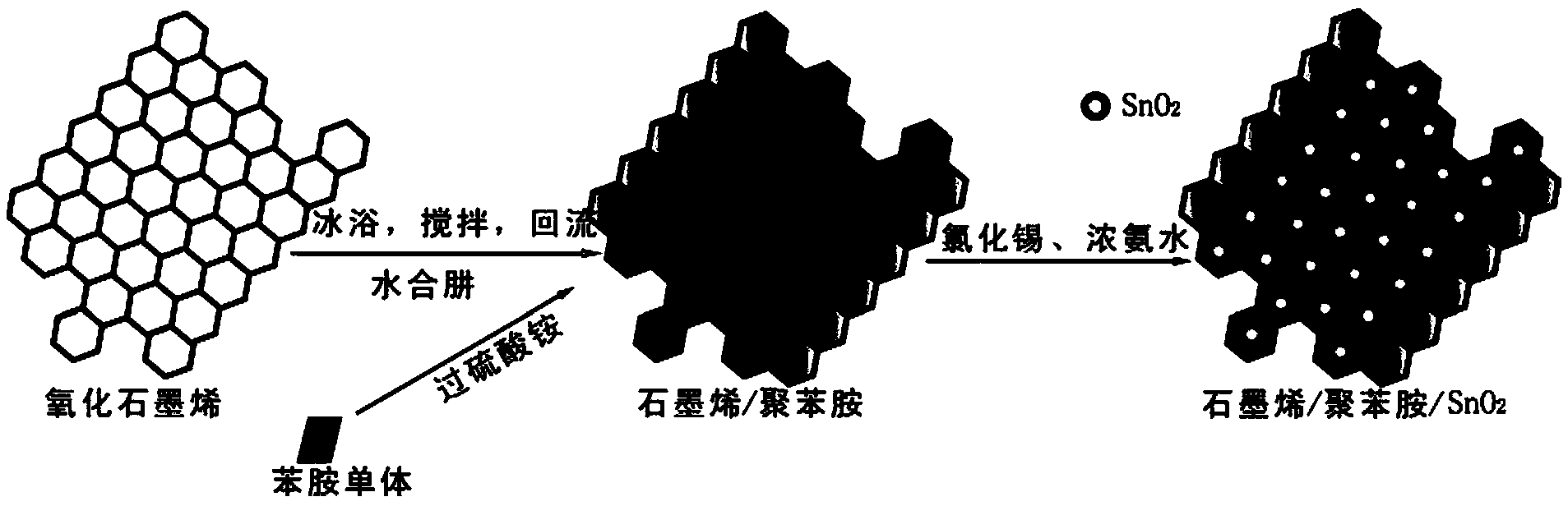

[0028] 2. A graphene / polyaniline / tin oxide composite material applied to supercapacitors, which is composed of graphene, polyaniline, and tin oxide. The polyaniline is coated on graphene, and the tin oxide grows on graphene coated with polyaniline.

[0029]3. A method for preparing a graphene / polyaniline / tin oxide composite material applied to a supercapacitor, comprising the steps of:

[0030] (1) Graphite oxide (0.005mol) was ultrasonically dispersed in deionized water (50m...

Embodiment 2

[0035] 1. Preparation of graphite oxide: Take flake graphite (1g), sodium nitrate (0.2g) and concentrated sulfuric acid (30ml) into a 1000ml beaker, add potassium permanganate (1g) while stirring with a stirrer, continue after adding Stir for 14h; then add deionized water (100ml) therein, and then add concentration of 30% hydrogen peroxide (10ml), at this moment, the suspension is yellow, and the solid is separated by filtration or centrifugation, and dried, namely It is graphite oxide, ready for use.

[0036] 2. A graphene / polyaniline / tin oxide composite material applied to supercapacitors, which is composed of graphene, polyaniline, and tin oxide. The polyaniline is coated on graphene, and the tin oxide grows on graphene coated with polyaniline.

[0037] 3. A method for preparing a graphene / polyaniline / tin oxide composite material applied to a supercapacitor, comprising the steps of:

[0038] (1) Graphite oxide (0.005mol) was ultrasonically dispersed in deionized water (50...

Embodiment 3

[0043] 1. Put flake graphite (3g), sodium nitrate (1.1g) and concentrated sulfuric acid (90ml) into a 1000ml beaker, add potassium permanganate (4.5g) while stirring in a stirrer, and continue stirring for more than 12 hours after adding; Add deionized water (350ml) thereto again, then add concentration and be 30% hydrogen peroxide (35ml), this moment suspension liquid is yellow, adopts the method for filtration or centrifugation, solid is separated, dry and stand-by.

[0044] 2. A graphene / polyaniline / tin oxide composite material applied to supercapacitors, which is composed of graphene, polyaniline, and tin oxide. The polyaniline is coated on graphene, and the tin oxide grows on graphene coated with polyaniline.

[0045] 3. A method for preparing a graphene / polyaniline / tin oxide composite material applied to a supercapacitor, comprising the steps of:

[0046] (1) Graphite oxide (0.005mol) was ultrasonically dispersed in deionized water (50ml) for 30 minutes, to which anilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com