Preparation method of nylon

A technology of nylon and nylon salt, which is applied in the field of polymer material synthesis, can solve problems such as difficult to obtain high molecular weight nylon 56, unbalanced ratio of pentamethylenediamine and adipic acid, difficult to obtain high molecular weight nylon, etc., to improve equipment utilization rate, shorten the polymerization cycle, and reduce the effect of polymerization energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

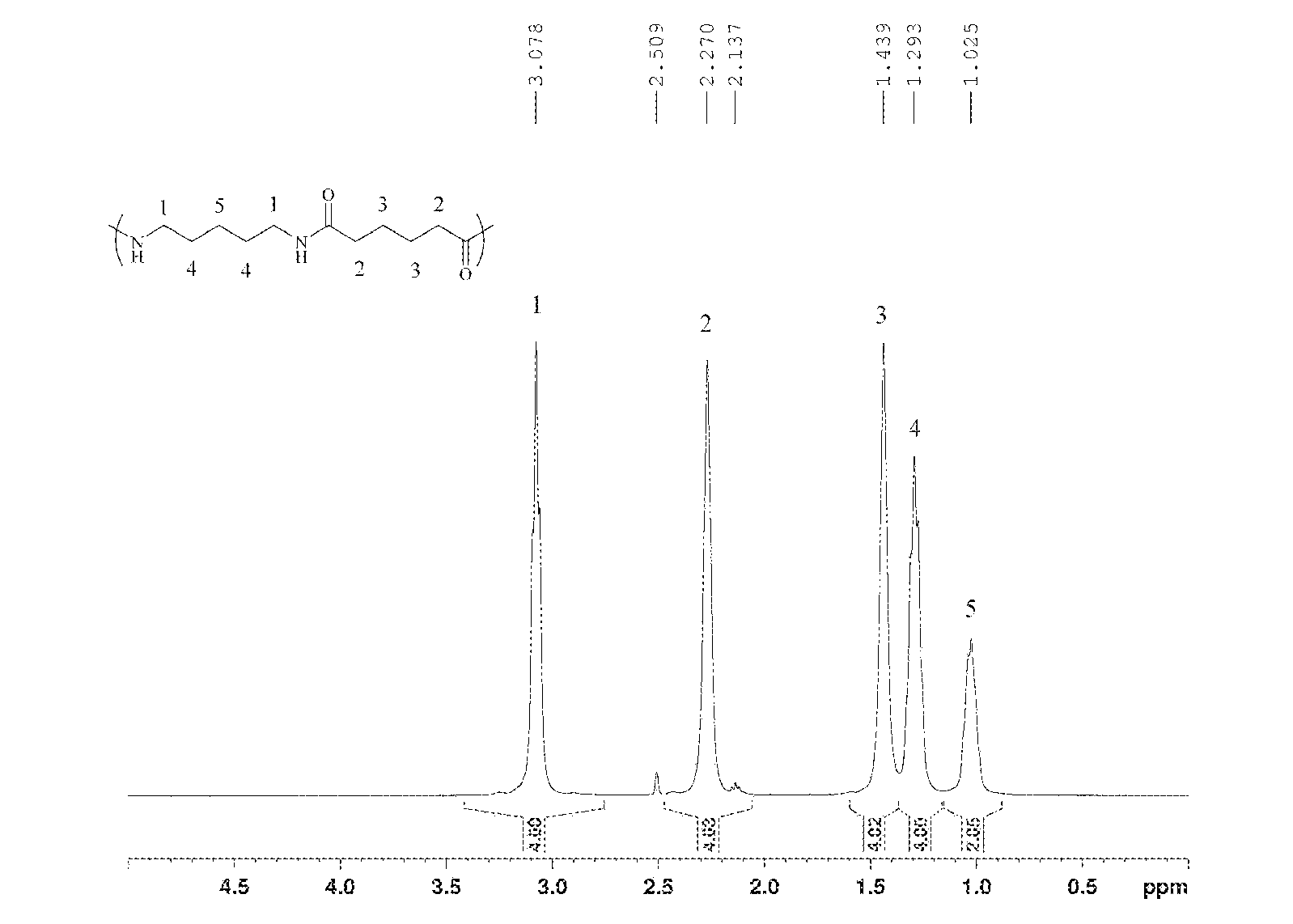

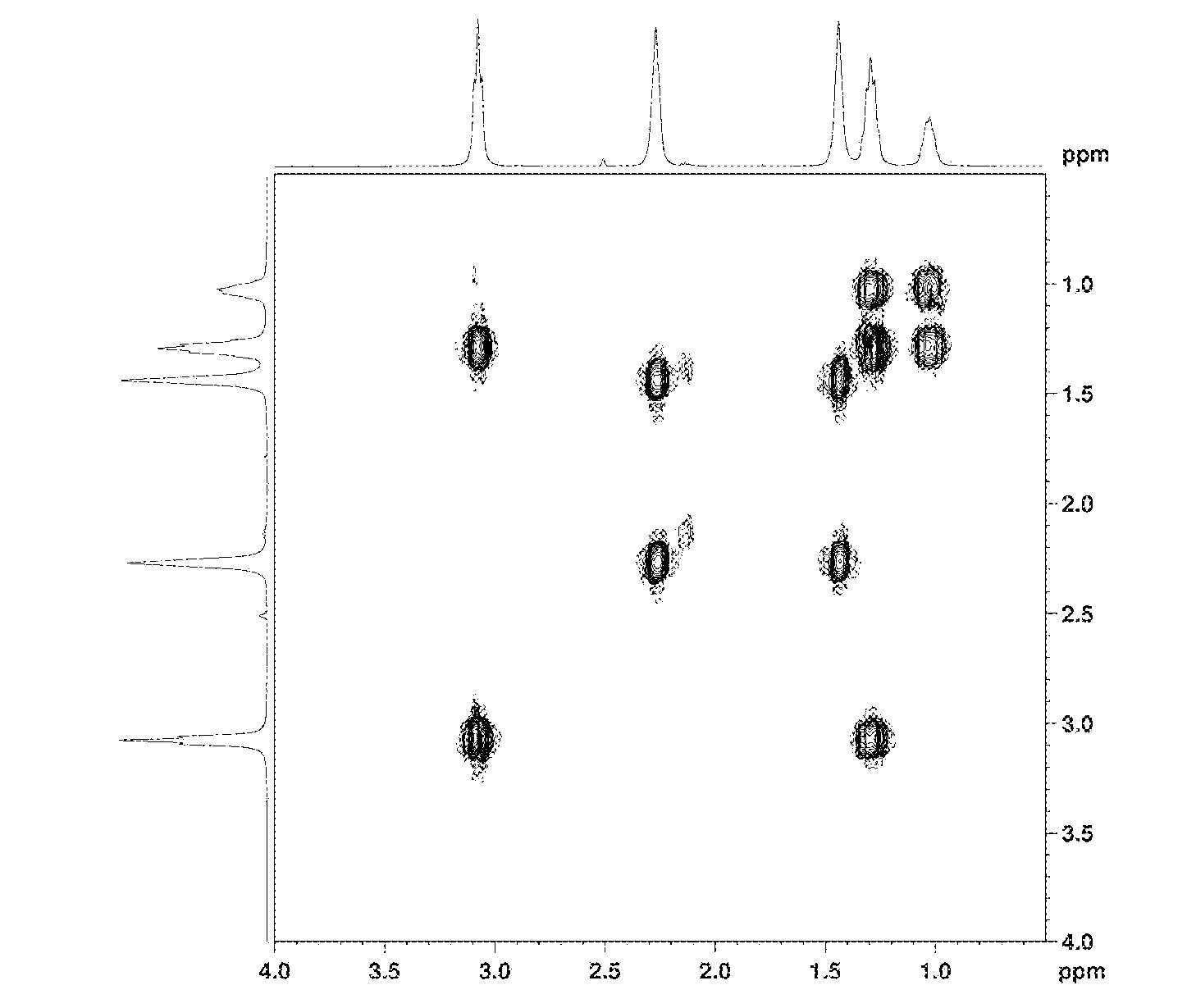

Image

Examples

Embodiment 1

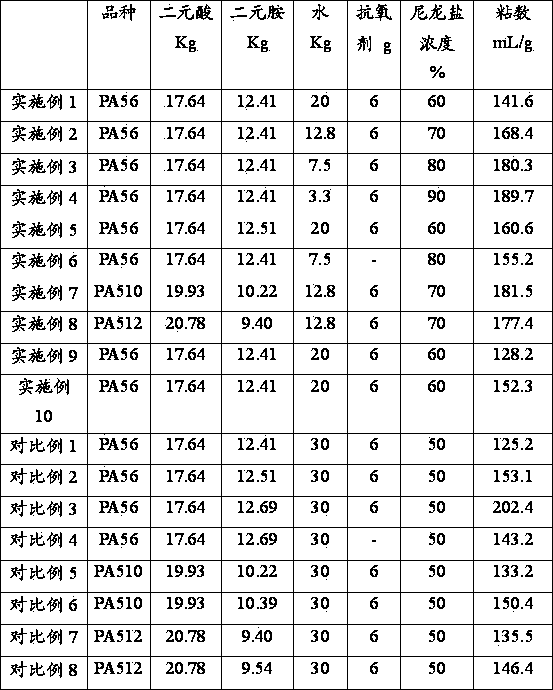

[0065] The 50-liter enamel salt-forming kettle was vacuumed and filled with nitrogen to replace the air three times, and protected with nitrogen. Added 20kg of pure water to the salt-forming kettle, and then added 12.41kg of Shandong Kaisai pentamethylenediamine (gas-phase normalization method purity 99.56%), start stirring, add 17.64 kg of superior grade adipic acid from Liaoning Petrochemical, and then add 6 g of antioxidant Bruggolen H10 (Bruggolen H 10, produced by Bruggolen, Germany) to prepare a nylon salt solution. Replace the air in 100 liters of K / SY166-2007 polymerization kettle with nitrogen, and transfer the nylon salt solution to the polymerization kettle. The temperature of the oil bath will rise to 1.73MPa when the pressure inside the kettle is raised, and then start to exhaust and keep the pressure and continue heating to 240 ℃, and then continue to heat and lower the pressure to normal pressure. When the pressure in the kettle reaches 265 ℃, evacuate to 0.06Mpa...

Embodiment 2

[0067] Operate in the same manner as in Example 1 except that the amount of water added in Example 1 is adjusted to 12.8 kg. The resulting nylon resin was tested for viscosity, and the results are shown in Table 3.

Embodiment 3

[0069] Operate in the same manner as in Example 1 except that the amount of water added in Example 1 is adjusted to 7.5 kg. The resulting nylon resin was tested for viscosity, and the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com