Method for preparing xylose and glucose from Zizania aquatica waste

A glucose and waste technology, applied in the field of glucose preparation, achieves the effects of mild reaction conditions, recyclable utilization, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

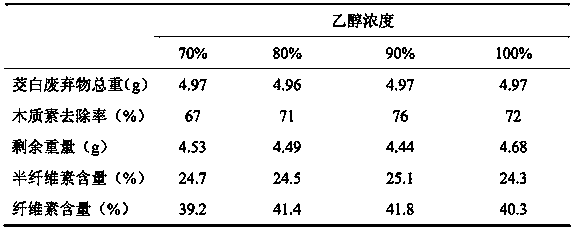

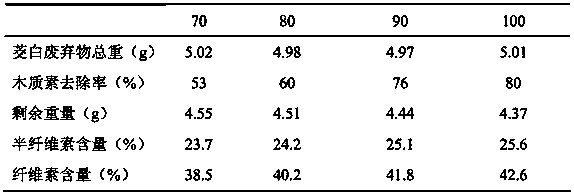

Embodiment 1

[0085] Firstly, the Zizania sheath leaves, leaves and leaf sheaths of Zizania wastes are dried overnight at 50°C, crushed with a pulverizer to particles with a particle size of 10-20mm, and leached with 90% ethanol at a temperature of 90°C for 1 hour. The solid-liquid ratio (g / ml) is 1:10, filter, and extract the obtained solid with formic acid at 70°C for 2 hours, the solid-liquid ratio (g / ml) is 1:10, filter, and separate the solid and liquid. The liquid is distilled under reduced pressure, and when the formic acid is recovered, the solid is obtained, which is the prepared xylose, and the recovery rate of xylose is 95% after detection and analysis; the obtained solid continues to use formic acid, and is leached at a temperature of 90 ° C for 5 hours , the solid-to-liquid ratio (g / ml) is 1:20, and the reaction produces glucose with a purity of 95%.

Embodiment 2

[0087] First dry the leaves, leaves and sheaths of Zizania zizania waste at 50°C overnight, crush them with a pulverizer to particles with a particle size of 10-20mm, and extract them with 80% ethanol at a temperature of 80°C for 2 hours. The solid-liquid ratio (g / ml) is 1:10, filter, and extract the obtained solid with formic acid at 75°C for 2 hours, the solid-liquid ratio (g / ml) is 1:20, filter, and separate the solid and liquid. The liquid is distilled under reduced pressure, and when the formic acid is recovered, the solid is obtained, which is the prepared xylose, and the recovery rate of xylose is 93% after detection and analysis; the obtained solid continues to use formic acid, and is leached for 4 hours at a temperature of 80°C , the solid-liquid ratio=1:10, the reaction produces glucose, and the purity of the glucose reaches 94%.

Embodiment 3

[0089] First, dry the leaves, leaves and leaf sheaths of Zizania zizania waste at 50°C overnight, crush them with a pulverizer to particles with a particle size of 10-20mm, and extract them with 70% ethanol at a temperature of 90°C for 1 hour. The solid-liquid ratio (g / ml) is 1:5, filter, and extract the obtained solid with formic acid at 70°C for 1 hour, the solid-liquid ratio (g / ml) is 1:10, filter, and separate the solid and liquid. The liquid is distilled under reduced pressure, and when the formic acid is recovered, the solid is obtained, which is the prepared xylose, and the recovery rate of xylose is 92% after detection and analysis; the obtained solid continues to use formic acid, and is leached for 4 hours at a temperature of 90°C , the solid-to-liquid ratio (g / ml) is 1:20, and the reaction produces glucose with a purity of 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com