A kind of grain boundary precipitation strengthened austenitic heat-resistant steel and its preparation method

A technology for austenitic heat-resistant steel and precipitation strengthening, which is applied to austenitic heat-resistant steel and its manufacturing field, and can solve the problem of unfavorable high-temperature creep resistance, easy coarsening and growth of heat-resistant steel, and decreased welding performance of materials. and other problems, to achieve the effect of improving high temperature mechanical properties, not easy to coarsen and grow up, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

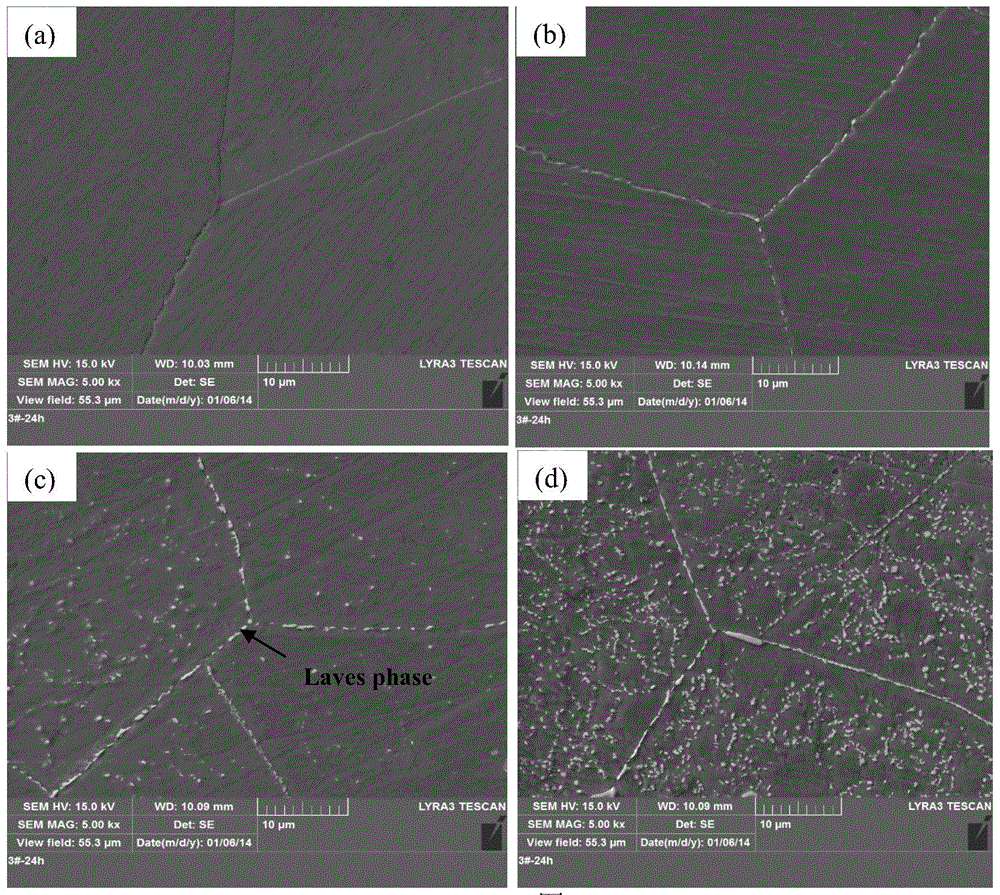

Image

Examples

preparation example Construction

[0027] The present invention also proposes a method for preparing the above-mentioned austenitic heat-resistant steel, which is characterized in that the method comprises the following steps:

[0028] (1) Put the metal iron, nickel, chromium, ferroniobium and ferroboron weighed according to the above ratio into the magnesia crucible;

[0029] (2) Put the magnesia crucible in the vacuum furnace and evacuate the vacuum furnace. When the pressure in the vacuum furnace is less than 10Pa, power is sent to the induction coil in the vacuum furnace. The induction coil generates current to heat the charge, and the power transmission power is from 10kw to 60kw, to melt the charge in the magnesia crucible;

[0030] (3) Further evacuate the vacuum furnace so that the vacuum degree in the vacuum furnace is less than or equal to 1Pa, and refine the charge for 15 minutes to remove oxygen, nitrogen and hydrogen in the charge;

[0031] (4) Let the magnesia crucible stand for 3 minutes to cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com