Antibacterial and deodorization cellulosic fiber and preparation method thereof

A cellulose fiber and fiber technology, which is applied in the field of antibacterial and deodorizing cellulose fiber and its preparation, can solve the problems affecting the antibacterial and deodorizing functionality of finished fibers and the loss of effective minerals, and achieve long-lasting and stable deodorizing function and long-lasting effect , wearing comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

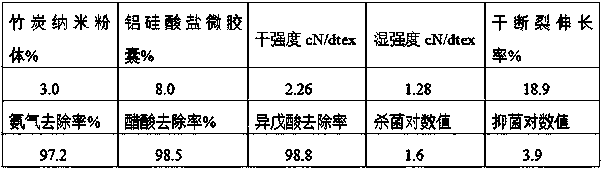

Embodiment 1

[0033] Preparation of 0.78 dtex×32mm antibacterial and deodorizing cellulose fibers:

[0034] (1) Preparation of bamboo charcoal nano-slurry

[0035] The preparation of bamboo charcoal nano-slurry is to add the bamboo charcoal powder with a particle size of 200~900 nanometers into 5.0wt% sodium hydroxide solution, stir for 45 minutes at a temperature of 41°C, add the dispersant dodecane after filtration Base benzene sulfonic acid, the quality that adds dispersant is 0.08wt% of bamboo charcoal nano-powder mass, after stirring 70 minutes under 800 rev / min rotating speeds, obtain the stable slurry that contains bamboo charcoal powder 35wt%, i.e. bamboo charcoal nano-powder.

[0036] (2) Preparation of aluminosilicate sustained-release microcapsules for use

[0037] The preparation of aluminosilicate sustained-release microcapsules includes:

[0038] (1) Pretreatment: Add natural aluminosilicate to 4.0wt% alkali solution, soak at 32°C for 35 minutes, wash at 41°C, filter and dry...

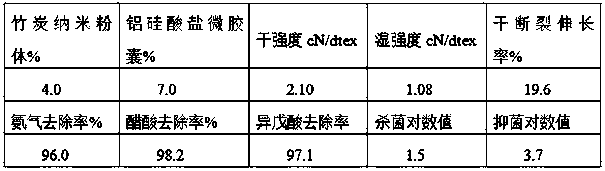

Embodiment 2

[0047] Preparation of 1.11dtex×32mm antibacterial and deodorizing cellulose fibers:

[0048] (1) Preparation of bamboo charcoal nano-slurry

[0049] The preparation of bamboo charcoal nano-slurry is to add the bamboo charcoal powder with a particle size of 200~900 nanometers into 4.0wt% sodium hydroxide solution, stir at 40°C for 60 minutes, add dispersant into dodecylbenzenesulfonic acid after filtration , the adding quality of dispersing agent is 0.10wt% of bamboo charcoal nano-powder mass, after stirring 80 minutes under 500 revs / min rotating speed, obtain the stable slurry that contains bamboo charcoal powder 30wt%, i.e. bamboo charcoal nano-powder.

[0050] (2) Preparation of aluminosilicate sustained-release microcapsules for later use

[0051] The preparation of aluminosilicate sustained-release microcapsules includes:

[0052] (1) Pretreatment: Add natural aluminosilicate to 3.0wt% alkali solution, soak at 30°C for 30 minutes, wash at 38°C, filter and dry at 77°C, th...

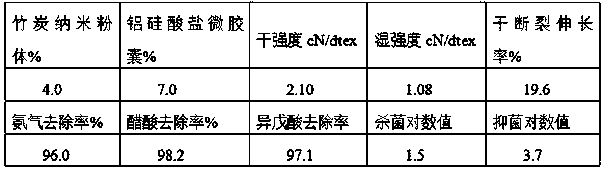

Embodiment 3

[0061] Preparation of 1.33dtex×38mm antibacterial and deodorizing cellulose fibers:

[0062] (1) Preparation of bamboo charcoal nano-slurry

[0063] The preparation of bamboo charcoal nano slurry is to add the bamboo charcoal powder with a particle size of 200~900 nanometers into 6.0wt% sodium hydroxide solution, stir at 43°C for 50 minutes, add the dispersant dodecylbenzenesulfonic acid after filtering, The mass of the dispersant added is 0.02wt% of the mass of the bamboo charcoal nano-powder, and after stirring for 60 minutes at a speed of 600 rpm, a stable slurry containing 40wt% of the bamboo-charcoal powder is obtained, i.e. the bamboo charcoal nano-powder.

[0064] (2) Preparation of aluminosilicate sustained-release microcapsules for use

[0065] The preparation of aluminosilicate sustained-release microcapsules includes:

[0066] (1) Pretreatment: Add natural aluminosilicate to 5.0wt% alkali solution, soak at 34°C for 40 minutes, wash at 42°C, filter and dry at 83°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com