An external heat preservation device suitable for the high temperature zone of the rotary kiln

A technology of rotary kiln and high temperature zone, used in rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as hidden safety hazards, high power consumption, loss of thermal insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

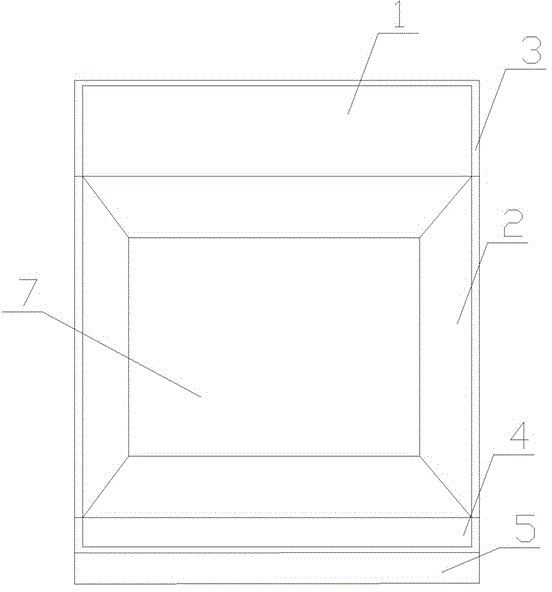

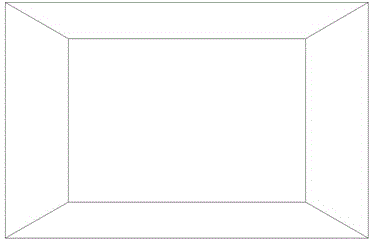

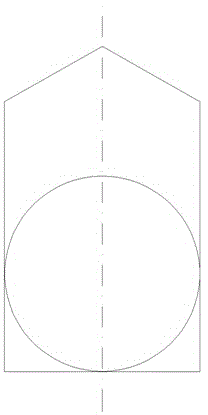

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a side heat insulating wall 2, sealed doors 6 at both ends, a triangular rain-snow and heat-preserving sealed ceiling 1, a fixed support 3, a supporting base 5, and a bottom heat insulating wall 4; a cuboid structure is formed by the fixed support, Two end sealing doors 6 are installed at both ends, and a round hole matching the shape of the rotary kiln is opened on the sealing door. The two sides are side insulation walls 2, and one side insulation wall is installed with a heat-resistant glass 7 The observation port of composition, the top is a triangular rain-snow and heat-preservation sealed ceiling 1, the bottom is the bottom insulation wall 4, and the bottom insulation wall is the support base 5 below.

[0021] In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com