Production equipment for biomass wood pellet fuel

A technology of pellet fuel and production equipment, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of design isolation, etc., and achieve the effects of saving energy consumption, high combustion rate, and reducing the amount of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following specific examples of the present invention are provided to further clearly understand the present invention, but they are not intended to limit the present invention. Parts not described in detail in the specific embodiments are obtained by using prior art, known technical means and industry standards. Unless otherwise stated, the percentages used in the present invention are all percentages by weight.

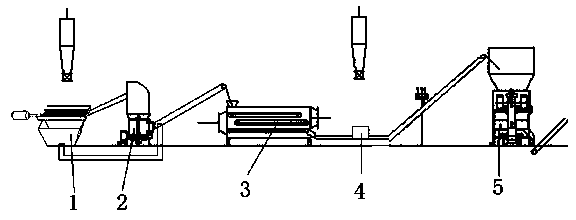

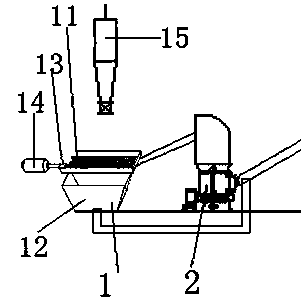

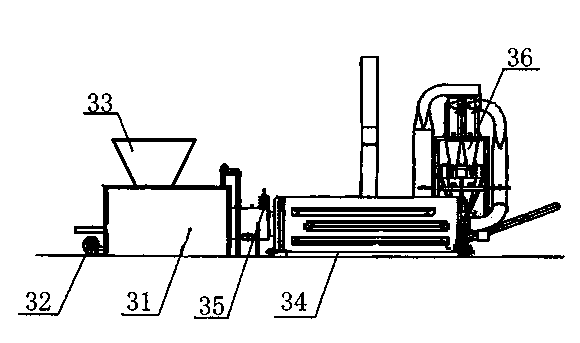

[0032] Please refer to the attached figure 1 , The biomass wood pellet fuel production equipment of the present invention includes a vibrating screen 1, a sawdust pulverizer 2, a tumble dryer 3, a storage room 4 and an extruded pellet machine 5 connected in sequence. After the sawdust raw material is crushed by the sawdust grinder 2, it is transported to the tumble dryer 3 for drying to control its moisture content, and then transported to the pellet machine 5 for extrusion molding to obtain biomass wood pellet fuel, and then passes through the conveyor b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com