Polylactic acid fiber reinforced polylactic acid/hydroxyapatite composite material and preparation method thereof

A technology of hydroxyapatite and polylactic acid fibers, which is applied in the field of medical materials, can solve the problems of low mechanical strength, poor mechanical properties, and poor load-carrying properties of polylactic acid, and achieve improved bone-guiding characteristics, low cost, and lightening The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

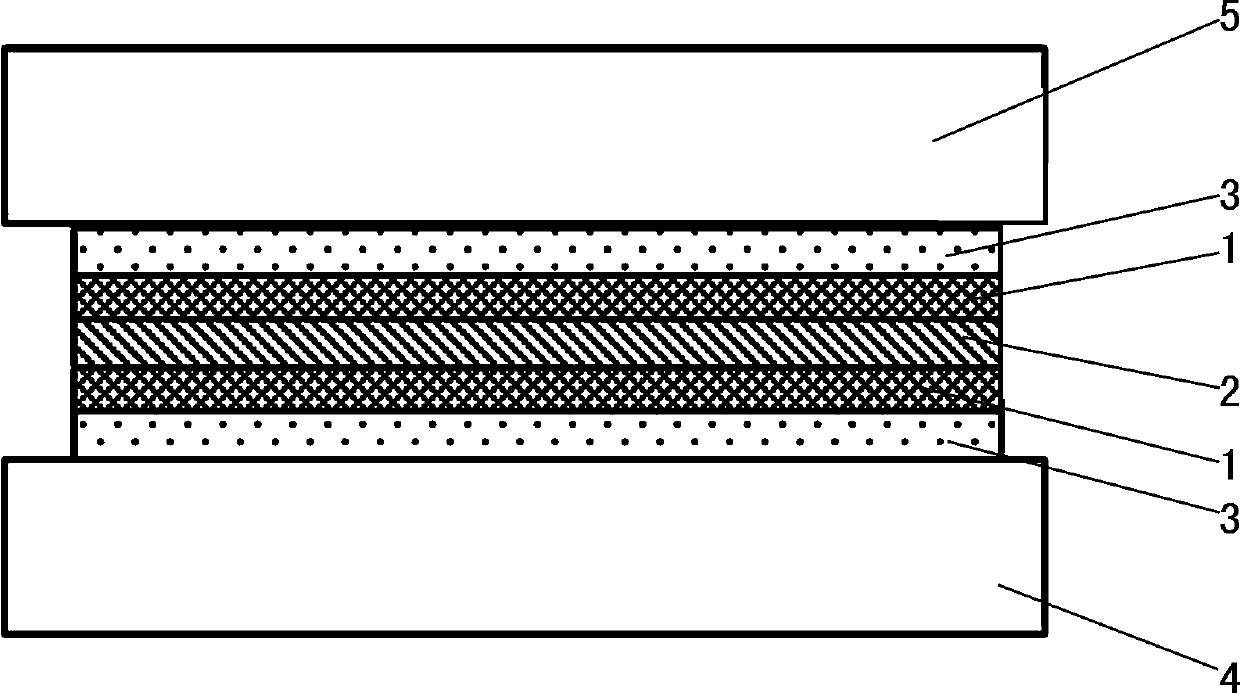

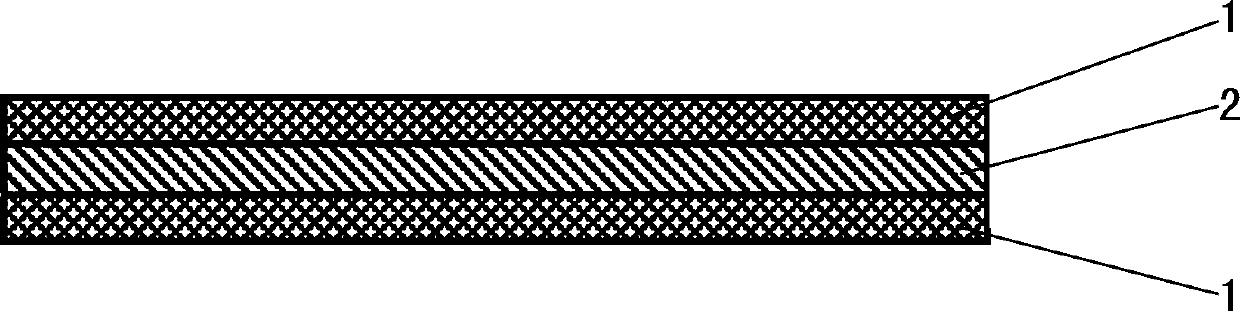

Image

Examples

Embodiment 1

[0034] The preparation method of the polylactic acid fiber reinforced polylactic acid / hydroxyapatite composite material of this embodiment includes the following steps in sequence:

[0035] (1) Put granular polylactic acid (both granular poly-L-lactic acid) in a vacuum drying oven, and dry at 65 °C for 24 hours to remove the moisture;

[0036] (2) mixing polylactic acid and hydroxyapatite obtained in step (1) at a ratio of 95% (weight) of polylactic acid and 5% (weight) of hydroxyapatite to obtain a mixed raw material;

[0037] In this step (2), put the polylactic acid and hydroxyapatite obtained in step (1) into a high-speed mixer according to the stated ratio, and mix for 3 minutes at a speed of 1500 rpm at 55°C , have to mix raw materials.

[0038] (3) Add the mixed raw materials obtained in step (2) to a twin-screw extruder for blending and extrusion, and use a granulator to make pellets from the extruded product;

[0039]In this step (3), the extrusion die equipped with...

Embodiment 2

[0053] The preparation method of the polylactic acid fiber reinforced polylactic acid / hydroxyapatite composite material of this embodiment includes the following steps in sequence:

[0054] (1) Put granular polylactic acid (both granular poly-L-lactic acid) in a vacuum drying oven, and dry at 65 °C for 24 hours to remove the moisture;

[0055] (2) mixing polylactic acid and hydroxyapatite obtained in step (1) at a ratio of 80% (weight) of polylactic acid and 20% (weight) of hydroxyapatite to obtain a mixed raw material;

[0056] In this step (2), put the polylactic acid and hydroxyapatite obtained in step (1) into a high-speed mixer according to the stated ratio, and mix for 5 minutes at a speed of 1000 rpm at 60°C , have to mix raw materials.

[0057] (3) Add the mixed raw materials obtained in step (2) to a twin-screw extruder for blending and extrusion, and use a granulator to make pellets from the extruded product;

[0058] In this step (3), the extrusion die equipped wi...

Embodiment 3

[0072] The preparation method of the polylactic acid fiber reinforced polylactic acid / hydroxyapatite composite material of this embodiment includes the following steps in sequence:

[0073] (1) Put granular polylactic acid (both granular poly-D,L-lactic acid) in a vacuum drying oven, and dry at 60 °C for 48 hours to remove the moisture;

[0074] (2) mixing polylactic acid and hydroxyapatite obtained in step (1) at a ratio of 75% (weight) of polylactic acid and 25% (weight) of hydroxyapatite to obtain a mixed raw material;

[0075] In this step (2), put the polylactic acid and hydroxyapatite obtained in step (1) into a high-speed mixer according to the stated ratio, and mix for 2 minutes at a speed of 2000 rpm at 50°C , have to mix raw materials.

[0076] (3) Add the mixed raw materials obtained in step (2) to a twin-screw extruder for blending and extrusion, and use a granulator to make pellets from the extruded product;

[0077] In this step (3), the extrusion die equipped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com