A kind of oam transmission optical fiber and its manufacturing method

A technology of transmission optical fiber and manufacturing method, which is applied in the field of OAM transmission optical fiber and its manufacturing, can solve problems such as difficult to realize OAM large-capacity transmission, OAM signal transmission mode crosstalk, and small transmission capacity, so as to achieve good optical performance and reliability, reduce Effect of power density and suppression of signal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

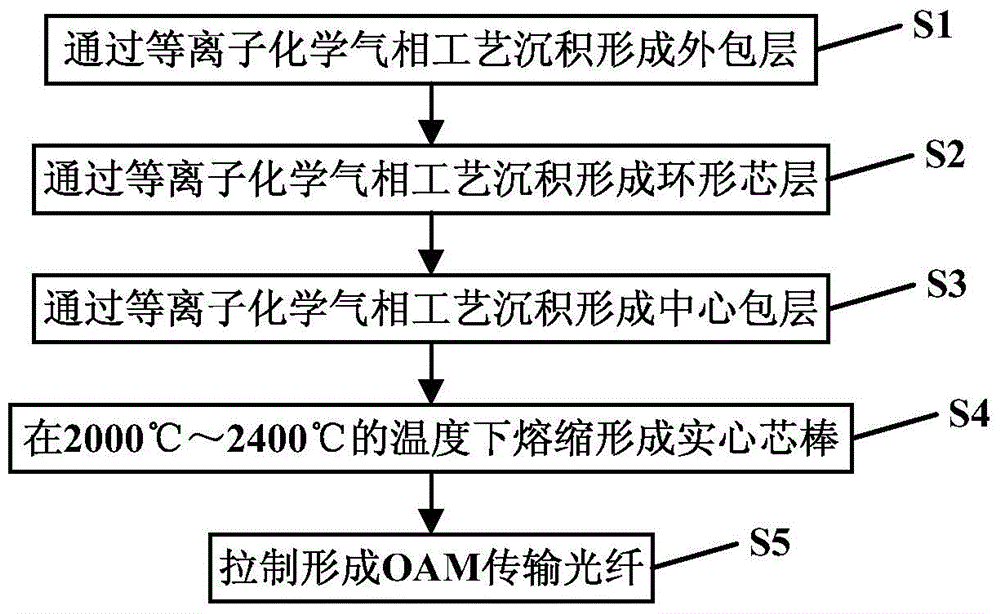

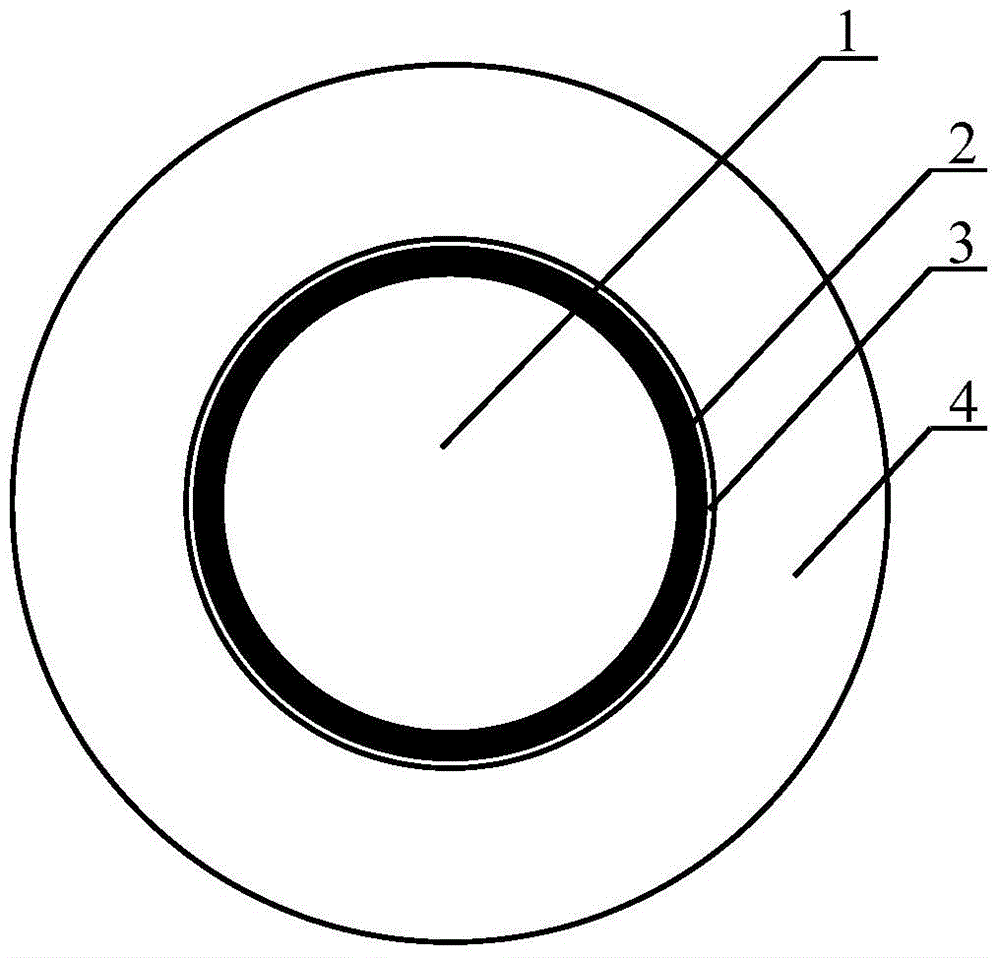

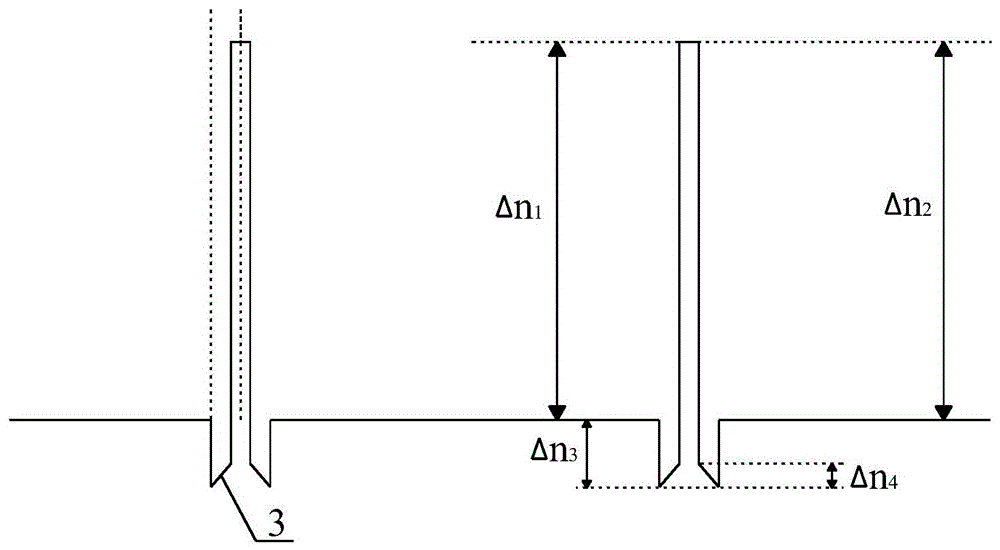

[0053] According to the opening percentage of the flowmeter, 70% silicon tetrachloride, 20% germanium tetrachloride, 10% phosphorus oxychloride and 5% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 1500 times to form the outer cladding layer 4 .

[0054] According to the opening percentage of the flowmeter, 70% silicon tetrachloride, 65% germanium tetrachloride and 1% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 350 times to form an annular core layer 2 .

[0055] According to the opening percentage of the flowmeter, 70% silicon tetrachloride, 20% germanium tetrachloride, 10% phosphorus oxychloride and 5% C 2 f 6 Put it into a quartz tube, and deposit 4750 times by using a plasma chemical vapor deposition process to form a central cladding layer 1 .

[0056] The quartz tube formed with the outer cladding layer 4, the annular core layer 2 and the central cladding layer 1 is pu...

Embodiment 2

[0060] According to the opening percentage of the flowmeter, put 80% of silicon tetrachloride, 10% of germanium tetrachloride and 30% of phosphorus oxychloride into the quartz tube, and use plasma chemical vapor deposition process to deposit 4800 times to form Outer cladding 4.

[0061] According to the opening percentage of the flowmeter, put 30% silicon tetrachloride and 20% germanium tetrachloride into the quartz tube, and deposit 300 times by plasma chemical vapor deposition process to form the annular core layer 2 .

[0062] According to the opening percentage of the flowmeter, put 80% silicon tetrachloride, 10% germanium tetrachloride and 30% phosphorus oxychloride into the quartz tube, and deposit 200 times by plasma chemical vapor deposition process to form Center cladding 1.

[0063] The quartz tube formed with the outer cladding layer 4, the annular core layer 2 and the central cladding layer 1 is put into a high-temperature graphite induction furnace, and the quart...

Embodiment 3

[0067] According to the opening percentage of the flowmeter, 50% silicon tetrachloride, 15% germanium tetrachloride, 12% phosphorus oxychloride and 10% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 600 times to form the outer cladding layer 4 .

[0068] According to the opening percentage of the flowmeter, 40% silicon tetrachloride, 60% germanium tetrachloride and 10% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 1200 times to form an annular core layer 2 .

[0069] According to the opening percentage of the flowmeter, 50% silicon tetrachloride, 15% germanium tetrachloride, 12% phosphorus oxychloride and 10% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 6000 times to form the central cladding layer 1 .

[0070]The quartz tube formed with the outer cladding layer 4, the annular core layer 2 and the central cladding layer 1 is pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com