OAM transmission fiber and manufacturing method thereof

A technology of transmission optical fiber and manufacturing method, applied in the field of OAM transmission optical fiber and its manufacturing, can solve the problems of difficulty in realizing OAM large-capacity transmission, OAM signal transmission mode crosstalk, small transmission capacity, etc., and achieves good optical performance and reliability. Power density, the effect of suppressing signal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

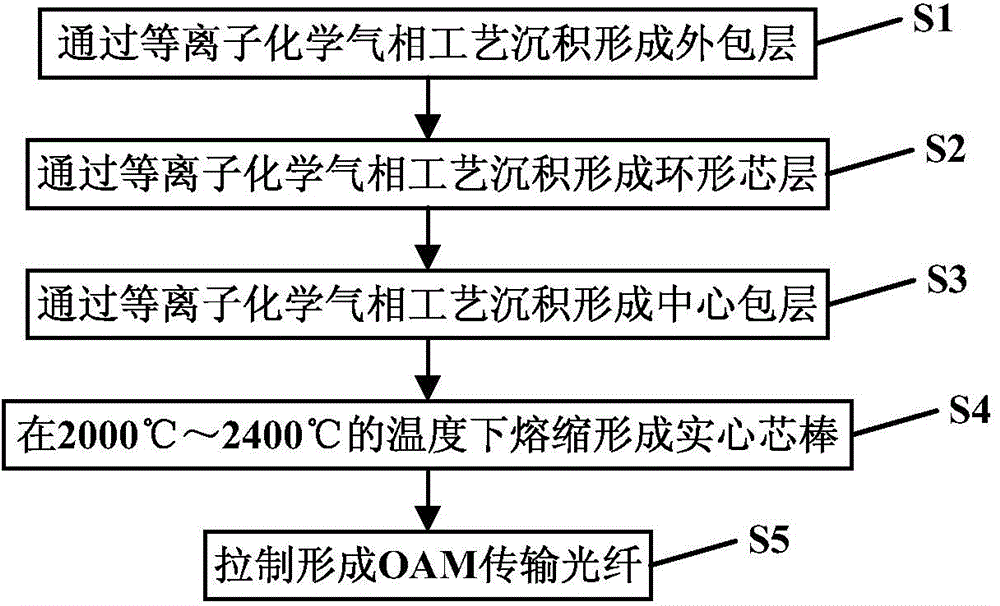

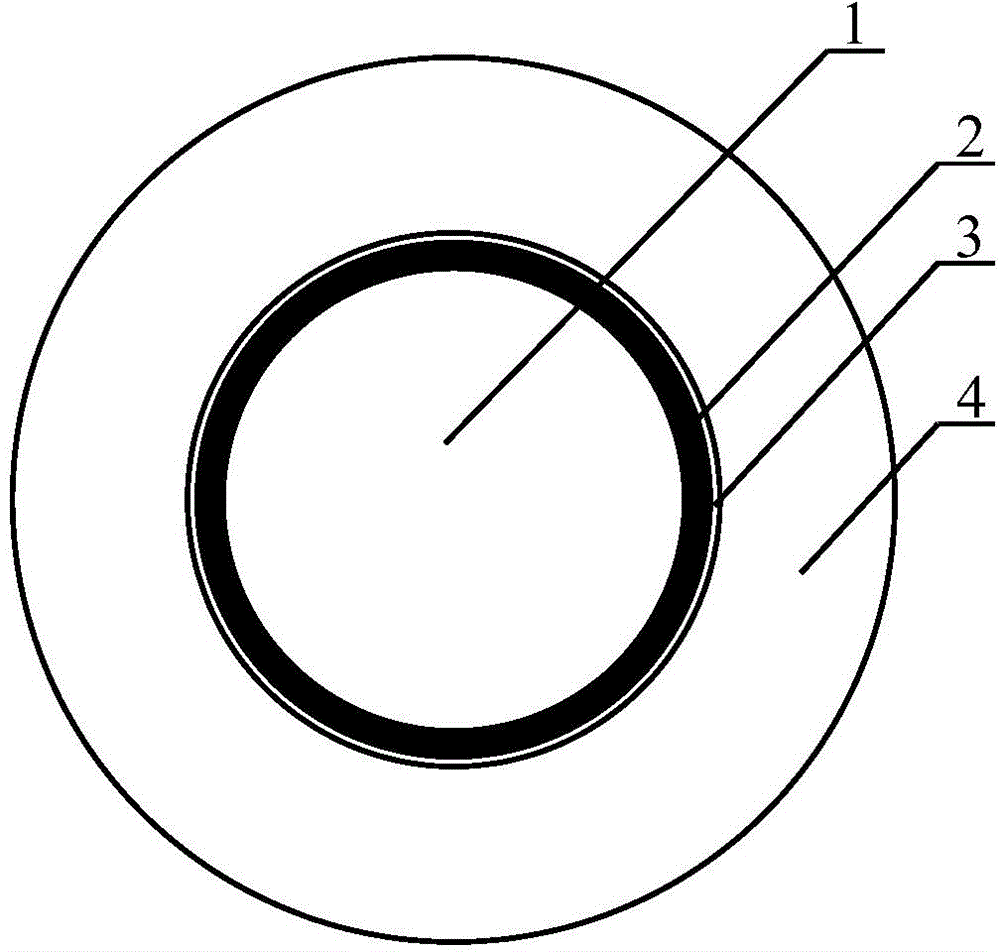

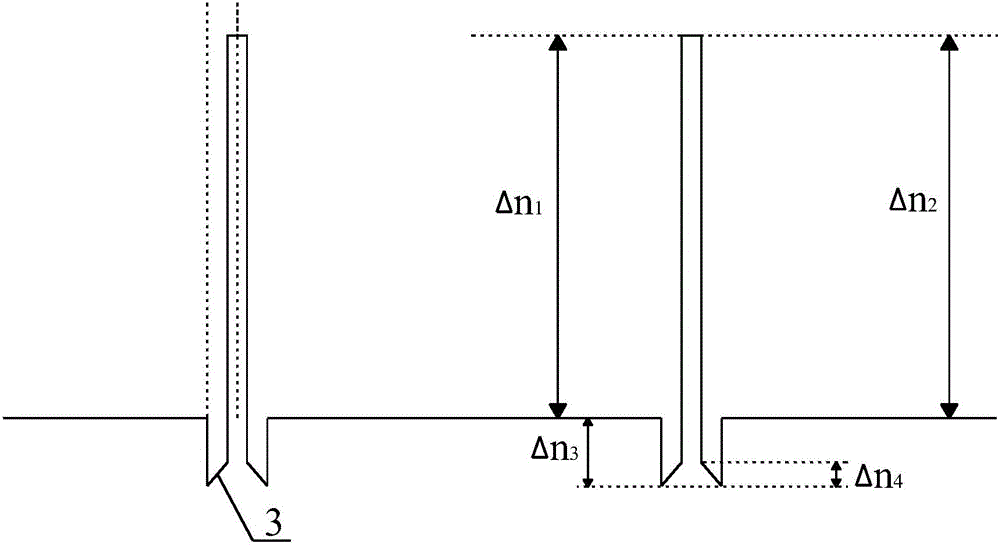

[0053] According to the opening percentage of the flowmeter, 70% silicon tetrachloride, 20% germanium tetrachloride, 10% phosphorus oxychloride and 5% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 1500 times to form the outer cladding layer 4 .

[0054] According to the opening percentage of the flowmeter, 70% silicon tetrachloride, 65% germanium tetrachloride and 1% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 350 times to form an annular core layer 2 .

[0055] According to the opening percentage of the flowmeter, 70% silicon tetrachloride, 20% germanium tetrachloride, 10% phosphorus oxychloride and 5% C 2 f 6 Put it into a quartz tube, and deposit 4750 times by using a plasma chemical vapor deposition process to form a central cladding layer 1 .

[0056] The quartz tube formed with the outer cladding layer 4, the annular core layer 2 and the central cladding layer 1 is pu...

Embodiment 2

[0060] According to the opening percentage of the flowmeter, put 80% of silicon tetrachloride, 10% of germanium tetrachloride and 30% of phosphorus oxychloride into the quartz tube, and use plasma chemical vapor deposition process to deposit 4800 times to form Outer cladding 4.

[0061] According to the opening percentage of the flowmeter, put 30% silicon tetrachloride and 20% germanium tetrachloride into the quartz tube, and deposit 300 times by plasma chemical vapor deposition process to form the annular core layer 2 .

[0062] According to the opening percentage of the flowmeter, put 80% silicon tetrachloride, 10% germanium tetrachloride and 30% phosphorus oxychloride into the quartz tube, and deposit 200 times by plasma chemical vapor deposition process to form Center cladding 1.

[0063] The quartz tube formed with the outer cladding layer 4, the annular core layer 2 and the central cladding layer 1 is put into a high-temperature graphite induction furnace, and the quart...

Embodiment 3

[0067] According to the opening percentage of the flowmeter, 50% silicon tetrachloride, 15% germanium tetrachloride, 12% phosphorus oxychloride and 10% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 600 times to form the outer cladding layer 4 .

[0068] According to the opening percentage of the flowmeter, 40% silicon tetrachloride, 60% germanium tetrachloride and 10% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 1200 times to form an annular core layer 2 .

[0069] According to the opening percentage of the flowmeter, 50% silicon tetrachloride, 15% germanium tetrachloride, 12% phosphorus oxychloride and 10% C 2 f 6 Put it into a quartz tube, and use plasma chemical vapor deposition process to deposit 6000 times to form the central cladding layer 1 .

[0070]The quartz tube formed with the outer cladding layer 4, the annular core layer 2 and the central cladding layer 1 is pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com