A method for preparing polycarboxylate superplasticizer macromonomer by using waste lithium battery

A technology of macromolecular monomer and polycarboxylic acid, which is applied in the field of cement additives, can solve the problems of not improving the recycling rate of resources, not reducing garbage discharge, and not being conducive to environmental protection, so as to avoid the control of reversible reactions and solve difficult problems. Effects of treatment, product stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

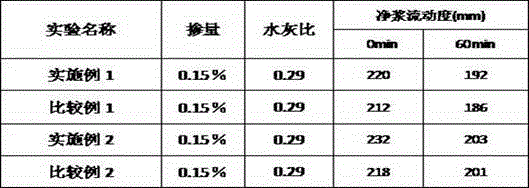

Embodiment 1

[0022] In a three-necked flask equipped with a stirring device, add 60 g of polyethylene glycol monomethyl ether with a molecular weight of 600, 0.7 g of metal Li, add phase transfer catalyst tetrabutylammonium hydrogen sulfate 1.7 g, and 7.65 g of propylene chloride under an inert gas protective atmosphere. g, heat up to 60°C and react for about 4.5 hours, then cool down to 50°C, remove the condenser, keep warm for one hour, and cool to room temperature to obtain allyl polyethylene glycol monomethyl ether polycarboxylate superplasticizer macromolecular unit body.

Embodiment 2

[0024] In a three-necked flask equipped with a stirring device, add 60 g of polyethylene glycol monomethyl ether with a molecular weight of 1200, 0.35 g of metal Li, and under an inert gas protection atmosphere, 1.7 g of phase transfer catalyst tetrabutylammonium hydrogen sulfate, 3.83 g of propylene chloride g, heat up to 60°C and react for about 4.5 hours, then cool down to 50°C, remove the condenser, keep warm for one hour, and cool to room temperature to obtain allyl polyethylene glycol monomethyl ether polycarboxylate superplasticizer macromolecular unit body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com