A kind of preparation method of waterproof potting material

A technology of potting materials and polyurethane prepolymers, which is applied in the field of preparation of waterproof potting materials, can solve problems such as inadequacies, and achieve the effects of excellent water resistance, good water resistance performance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

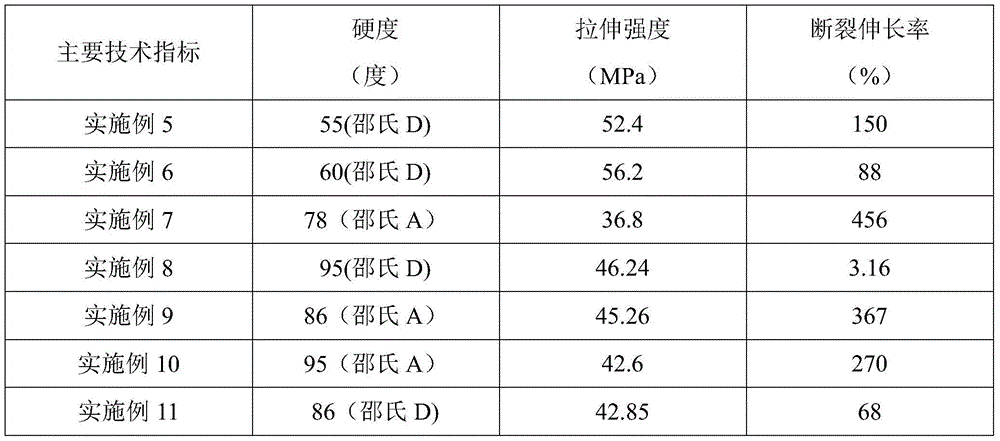

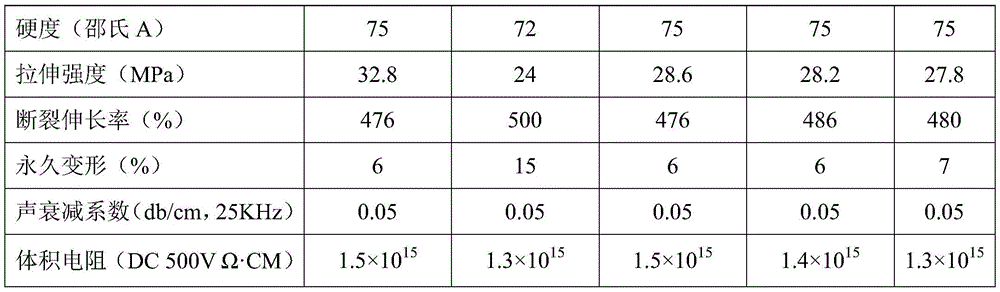

Examples

Embodiment 1

[0057] The preparation method of a kind of waterproof potting material of the present embodiment is carried out according to the following steps:

[0058] 1. Add 100g of polyoxypropylene diol with a molecular weight of 4000 and 9.08g of MDI-100 into the reaction kettle, stir, heat to 80°C, and continue to stir for 2 hours. The percentage of isocyanate is 1.5%, and the polyurethane prepolymer is prepared. Into nitrogen airtight storage;

[0059] 2. Fully mix 100g polyurethane prepolymer with 3.03g molecular weight epoxy resin of 400 to prepare A component;

[0060] 3. Heat and melt 1.319g1,4-butanediol (curing agent) and 0.36g trimethylolpropane (curing agent) and heat and melt with 103g auxiliary agent 2, 0.06gN-dimethylbenylamine (reaction accelerator) ), 2.06g aminopropyltriethoxysilane (silane coupling agent) and 0.05g dibutyltin dilaurate (reaction accelerator) are fully mixed to prepare B component;

[0061] 4. Mix and cast the component A prepared in step 2 and the com...

Embodiment 2

[0065] The preparation method of a kind of waterproof potting material of the present embodiment is carried out according to the following steps:

[0066] 1. Add 100g of polyoxypropylene diol with a molecular weight of 2000 and 17.67g of T-100 into the reaction kettle, stir, heat to 84°C, continue to stir for 2h, and test that the percentage of isocyanate is 3.25%, and the polyurethane prepolymer is obtained. Into nitrogen airtight storage;

[0067] Two, 100g polyurethane prepolymer and 5.66g molecular weight are the epoxy resin of 400 fully mixed, make A component;

[0068] 3. Heat and melt 0.7g of 1,4-butanediol (curing agent) and 6.06g of 3,3'-dichloro-4,4'-diaminodiphenylmethane (curing agent) with 42.2g of auxiliary agent 3, 0.11g N-dimethyl benzyl amine (reaction accelerator) and 2.11g aminopropyltriethoxysilane (silane coupling agent) fully mix, make B component;

[0069] 4. Mix and cast the component A prepared in step 2 and the component B prepared in step 3, cure a...

Embodiment 3

[0073] The preparation method of a kind of waterproof potting material of the present embodiment is carried out according to the following steps:

[0074] 1. Add 100g of polytetrahydrofuran with a molecular weight of 2000 and 32.3g of MDI-100 into the reaction kettle, stir, heat to 85°C, continue to stir for 2h, and test that the percentage of isocyanate is 6%, that is, the polyurethane prepolymer is prepared, and filled with nitrogen Sealed storage;

[0075] Two, 100g polyurethane prepolymer and 5.03g molecular weight are the epoxy resin of 400 fully mixed, make A component;

[0076] 3. Heat and melt 11.5g of 1,4-butanediol (curing agent), mix with 10g of auxiliary agent 1, 0.1g of N-dimethylbenylamine (reaction accelerator) and 2.1g of aminopropyltriethoxysilane (silane Coupling agent) is fully mixed to obtain component B;

[0077] 4. Mix and cast the component A prepared in step 2 and the component B prepared in step 3, cure at room temperature for 24 hours, and then cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com