Super-tough nylon 66 composite material and preparation method thereof

A composite material and nylon technology, which is applied in the field of super tough nylon 66 composite material and its preparation, can solve the problems of low gloss, poor low temperature toughness, and little improvement in impact toughness of toughened nylon, and achieves high gloss and high tensile strength. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

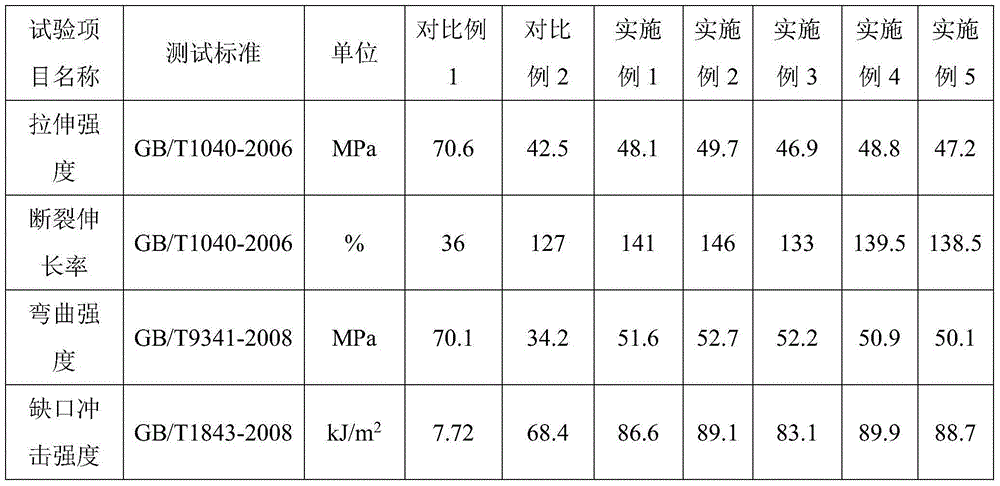

Examples

preparation example Construction

[0026] The preparation method of super-tough nylon 66 composite material, comprises steps:

[0027] 1) Mix the raw materials evenly;

[0028] 2) Extrude, granulate and dry.

Embodiment 1

[0031] A kind of super-tough nylon 66 composite material, its formula is made up as following table 1:

[0032] Table 1:

[0033] raw material

Embodiment 2

[0035] A kind of super-tough nylon 66 composite material, its formula composition is as follows table 2:

[0036] Table 2:

[0037] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com