Multifunctional environment-friendly waterproof paint

A waterproof coating and multi-functional technology, applied in the field of architectural coatings and multi-functional environmental protection waterproof coatings, can solve the problems of increased cost, aging, poor durability, etc., and achieve the effects of increasing adhesion, enhancing acid resistance, and avoiding demulsification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

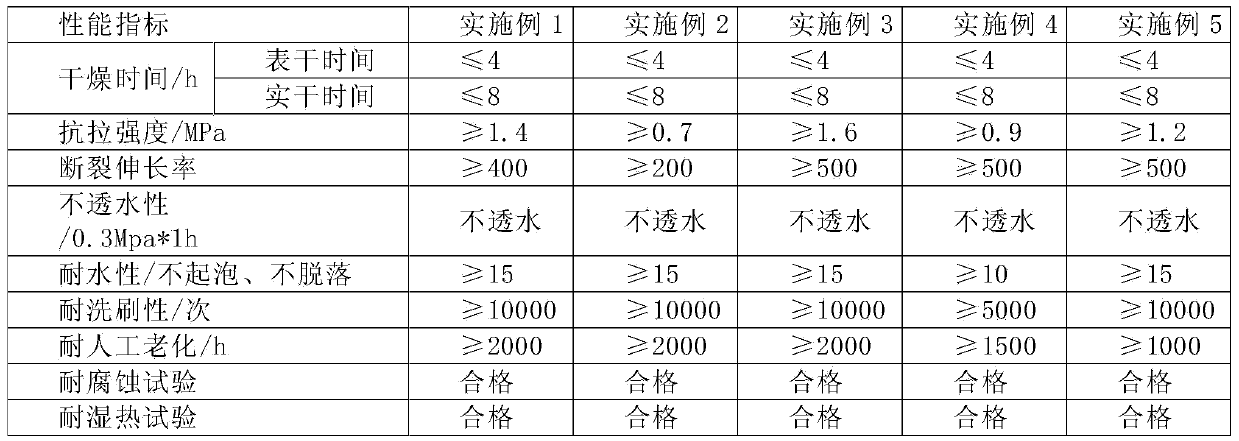

Examples

Embodiment 1

[0019] The method for preparing the multifunctional environmental protection waterproof coating in this embodiment comprises the following steps:

[0020] 1), select raw materials:

[0021] Among them: water-based acrylic emulsion: 35 parts; styrene-butadiene emulsion: 10 parts; titanium dioxide: 13 parts; light calcium carbonate: 5 parts; ceramic fiber: 3 parts; molybdenum disulfide: 5 parts; carboxycellulose: 5 parts; Dispersant: 3 parts; adhesion promoter: 0.8 parts; UV absorber: 0.3 parts; antiaging agent: 0.6 parts; defoamer: 0.8 parts; thickener: 2 parts; : 15.5 parts; Described dispersant is dispersant 5040, and described ultraviolet absorber is the ultraviolet absorber UV-9 of Bailingwei Technology Co., Ltd.; Described antioxidant is Lianyungang Ningkang Chemical Co., Ltd. antioxidant 264; Described defoamer It is the defoamer NXZ of BASF Co., Ltd.; the thickener is inorganic bentonite; and the film-forming aid is American Eastman TEXANOL ester alcohol film-forming ai...

Embodiment 2

[0026] The difference between this embodiment and embodiment 1 is that the raw materials selected in this embodiment and their proportioning ratio are as follows:

[0027] Water-based acrylic emulsion: 20 parts; styrene-butadiene emulsion: 20 parts; titanium dioxide: 18 parts; light calcium carbonate: 5 parts; ceramic fiber: 3 parts; molybdenum disulfide: 5 parts; carboxy cellulose: 5 parts; dispersant : 3 parts; adhesion promoter: 0.8 parts; UV absorber: 0.3 parts; anti-aging agent: 0.6 parts; defoamer: 0.8 parts; thickener: 2 parts; share.

Embodiment 3

[0029] The difference between this embodiment and embodiment 1 is that the raw materials selected in this embodiment and their proportioning ratio are as follows:

[0030] Water-based acrylic emulsion: 30 parts; styrene-butadiene emulsion: 10 parts; titanium dioxide: 18 parts; light calcium carbonate: 5 parts; ceramic fiber: 3 parts; molybdenum disulfide: 5 parts; carboxy cellulose: 5 parts; dispersant : 3 parts; adhesion promoter: 0.8 parts; UV absorber: 0.3 parts; anti-aging agent: 0.6 parts; defoamer: 0.8 parts; thickener: 2 parts; share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com