Method for fabricating acidolysis acetylated starch adhesive and application of acidolysis acetylated starch adhesive

A kind of technology of acetylated starch and production method, applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve the problems of appearance, bonding strength and water resistance to be improved, achieve good appearance, improve Effect of improving appearance and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Technological process: Add waxy cornstarch to 0.75mol / L hydrochloric acid aqueous solution to prepare 30-40% starch milk and carry out acid hydrolysis. Use sodium hydroxide solution to adjust the pH to 8.0 to 8.4, slowly add acetic anhydride which accounts for 6% of the dry weight of starch, and react at 25°C for 1 hour; after the reaction, adjust the pH of the system to 6.5, and use ammonium persulfate as the trigger agent, maintain the pH at 4.0, and pre-initiate for 30 minutes in a 70°C water bath. Prepare a polyvinyl alcohol (PVA) solution with a mass concentration of 10%, mix it evenly with the starch paste, adjust the pH=4.0 with NaOH solution, start to drop vinyl acetate monomer after stabilization, and carry out grafting reaction in a water bath at 70°C. The reaction time is 3 hours, the vinyl acetate monomer addition time is 1.5 hours, and a certain amount of initiator is added after the monomer addition is completed. A certain am...

Embodiment 2

[0023] Technological process: Add ordinary cornstarch into 0.75mol / L hydrochloric acid aqueous solution to prepare 30-40% starch milk and carry out acid hydrolysis. Use sodium hydroxide solution to adjust the pH to 8.0 to 8.4, slowly add acetic anhydride which accounts for 6% of the dry weight of starch, and react at 25°C for 1 hour; after the reaction, adjust the pH of the system to 6.5, and use ammonium persulfate as the trigger agent, maintain the pH at 4.0, and pre-initiate for 30 minutes in a 70°C water bath. Prepare a polyvinyl alcohol (PVA) solution with a mass concentration of 10%, mix it evenly with the starch paste, adjust the pH=4.0 with NaOH solution, start to drop vinyl acetate monomer after stabilization, and carry out grafting reaction in a water bath at 70°C. The reaction time is 3 hours, the monomer dropping time is 1.5 hours, and a certain amount of initiator is added after the monomer dropping is completed. A certain amount of ...

Embodiment 3

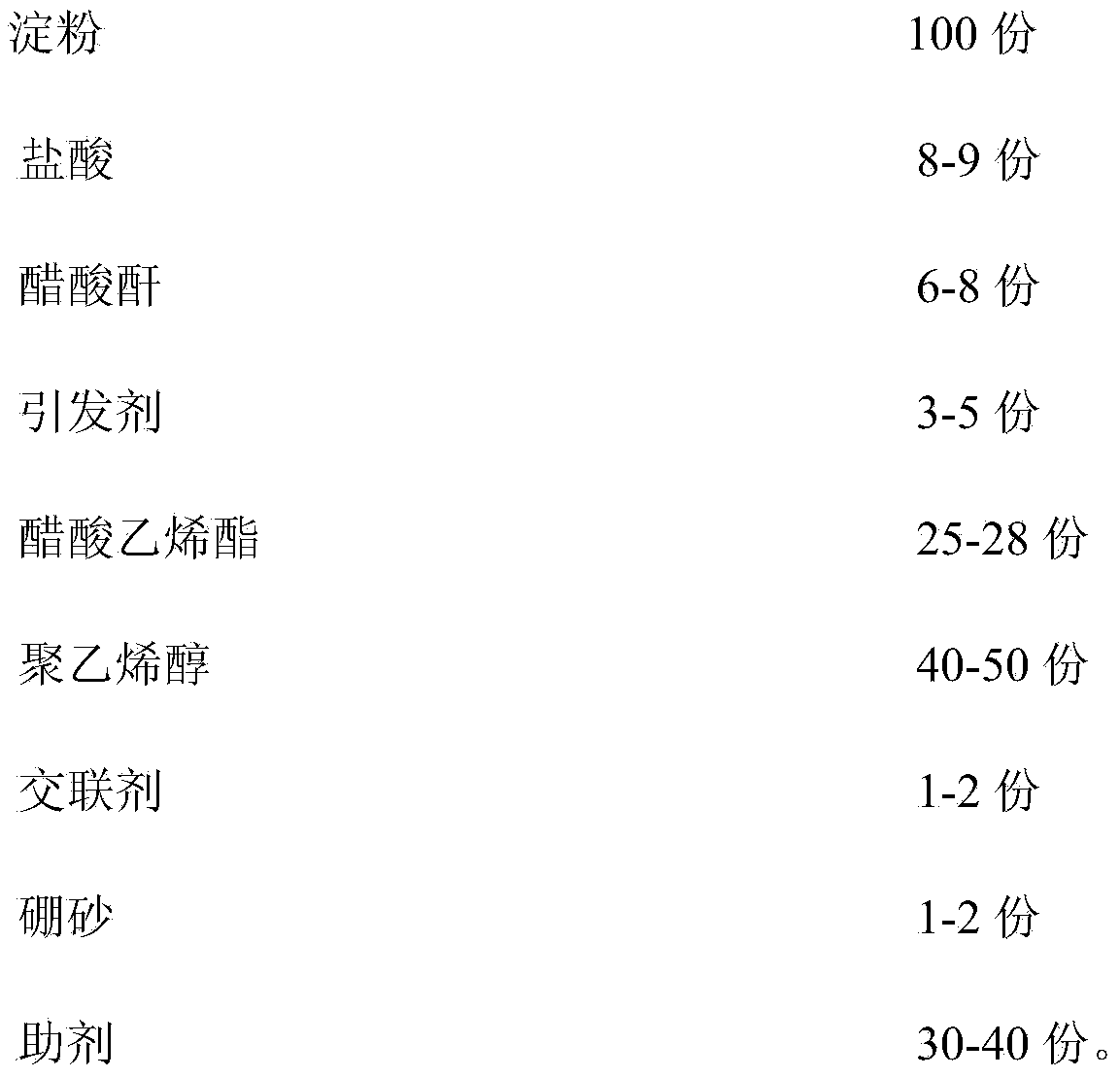

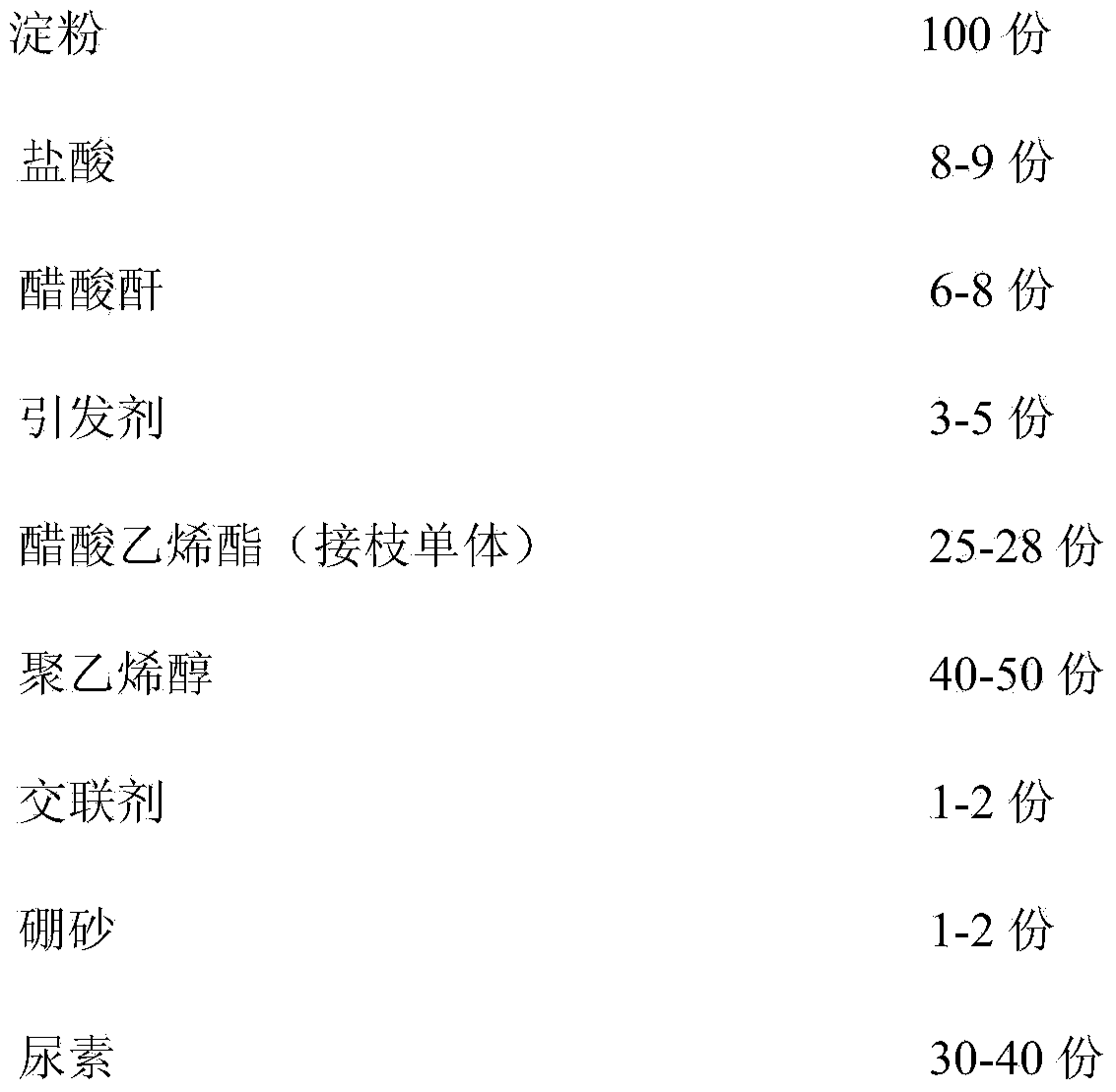

[0025] Recipe (by mass):

[0026] Technological process: Add tapioca starch to 0.75mol / L aqueous hydrochloric acid solution to make 30-40% starch milk and carry out acid hydrolysis. Use sodium hydroxide solution to adjust the pH to 8.0 to 8.4, slowly add acetic anhydride which accounts for 6% of the dry weight of starch, and react at 25°C for 1 hour; after the reaction, adjust the pH of the system to 6.5, and use ammonium persulfate as the trigger agent, maintain the pH at 4.0, and pre-initiate for 30 minutes in a 70°C water bath. Prepare a polyvinyl alcohol (PVA) solution with a mass concentration of 10%, mix it evenly with the starch paste, adjust the pH=4.0 with NaOH solution, start to drop vinyl acetate monomer after stabilization, and carry out grafting reaction in a water bath at 70°C. The reaction time is 3 hours, the monomer dropping time is 1.5 hours, and a certain amount of initiator is added after the monomer dropping is completed. A certain amount of cross-link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com