Tungsten oxide and zirconium oxide high-temperature solar selective absorption coating and production method thereof

An absorption coating, selective technology, applied in the field of solar energy utilization, to achieve the effect of excellent high temperature stability and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

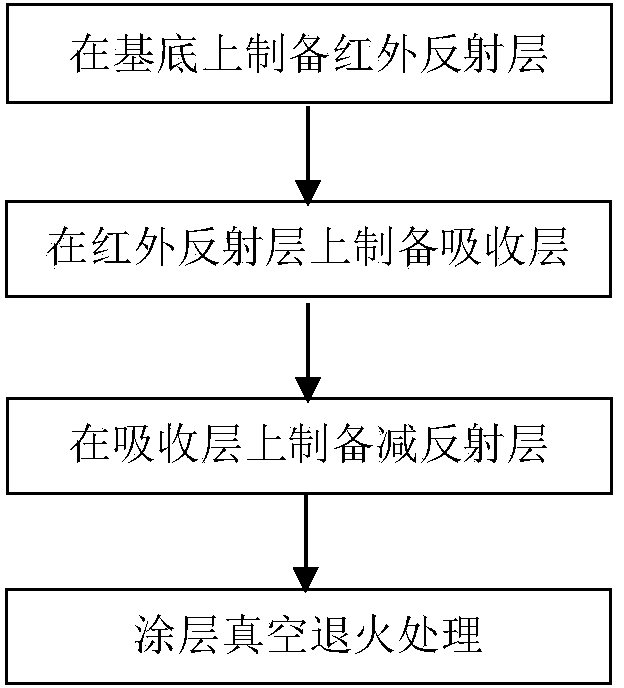

[0026] A kind of WO provided by the present invention x / ZrO x The preparation method of high temperature solar energy selective absorbing coating, such as figure 2 shown, including the following steps:

[0027] Step 1: preparing the first infrared emitting layer on the substrate;

[0028] Adopt pure metal target DC or intermediate frequency magnetron sputtering method, the pure metal target is Cu target or Ag target (purity is 99.99%), prepared with Ar gas as the sputtering gas, the substrate is made of high speed steel, and the vacuum chamber is placed before sputtering The background vacuum is pre-pumped to 4×10 -3 ~5×10 -3 Pa, the inert gas Ar gas is introduced as the sputtering atmosphere, the Ar gas flow rate is 1000-1400sccm, the sputtering distance is adjusted to 130-150mm, and the sputtering pressure is adjusted to 2×10 -1 ~4×10 -1 Pa, turn on the power supply of the sputtering target of the pure metal target, adjust the sputtering voltage to 380-450V, and the ...

Embodiment 1

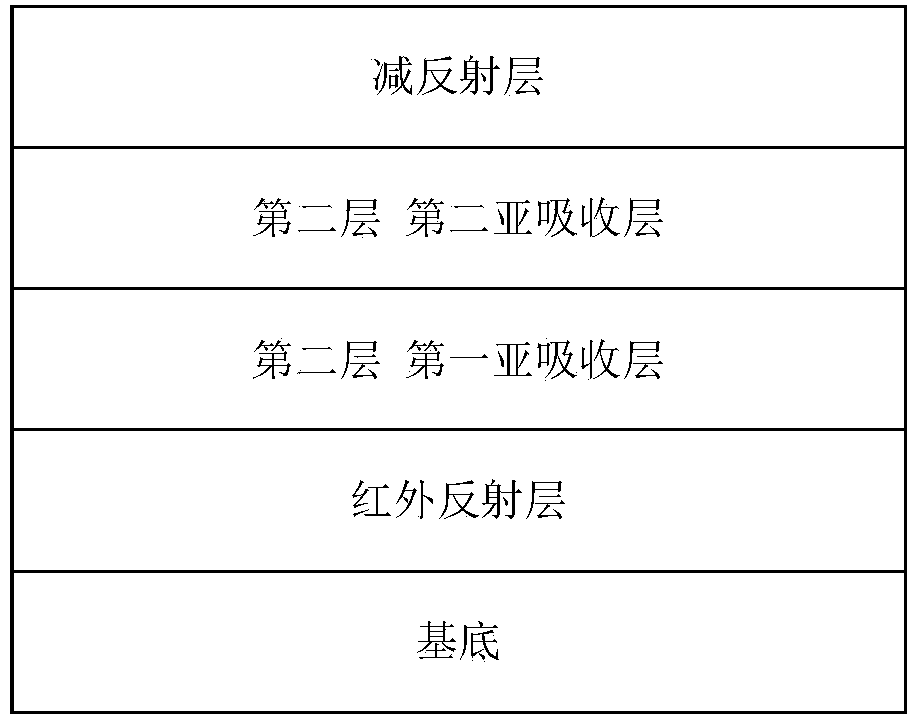

[0037] This embodiment provides a WO x / ZrO x Solar energy selective absorption coating, the coating includes three coatings, divided into the first layer of infrared reflection layer, the second layer of absorption layer, the third layer of anti-reflection layer, the thickness of the first layer of Cu film is 170nm, the second layer The total thickness is 360nm, where the first sublayer WO x +ZrO x The film thickness is 200nm, the second sublayer WO x +ZrO x The film thickness is 160nm, ZrO in the first sublayer x The volume percentage is 60%, the rest is WO x ; the second sublayer ZrO x The volume percentage is 40%, the rest is WO x ; the third layer of ZrO x The film thickness was 120 nm. Preparation of the above WO x / ZrO x The method for solar energy selective absorbing coating, comprises the following steps:

[0038] Step 1: preparing the first infrared emitting layer on the substrate;

[0039] The Cu target with a purity of 99.99% is selected, and the base ...

Embodiment 2

[0049] This embodiment provides a WO x / ZrO x Solar energy selective absorption coating, the coating includes three coatings, divided into the first layer of infrared reflection layer, the second layer of absorption layer, the third layer of anti-reflection layer, the thickness of the first layer of Cu film is 140nm, the second layer The total thickness is 300nm, where the first sublayer WO x +ZrO x The film thickness is 150nm, the second sublayer WO x +ZrO x The film thickness is 150nm, ZrO in the first sublayer x The volume percentage is 55%, the rest is WO x ; the second sublayer ZrO 2 The volume percentage is 35%, the rest is WO x ; the third layer of ZrO 2 The film thickness was 150 nm. Preparation of the above WO x / ZrO x The method for solar energy selective absorbing coating, comprises the following steps:

[0050] Step 1: preparing the first infrared emitting layer on the substrate;

[0051] The Cu target with a purity of 99.99% is selected, and the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com