Coupling agent for eliminating end face roughness influence and improving vertical and horizontal wave testing effect

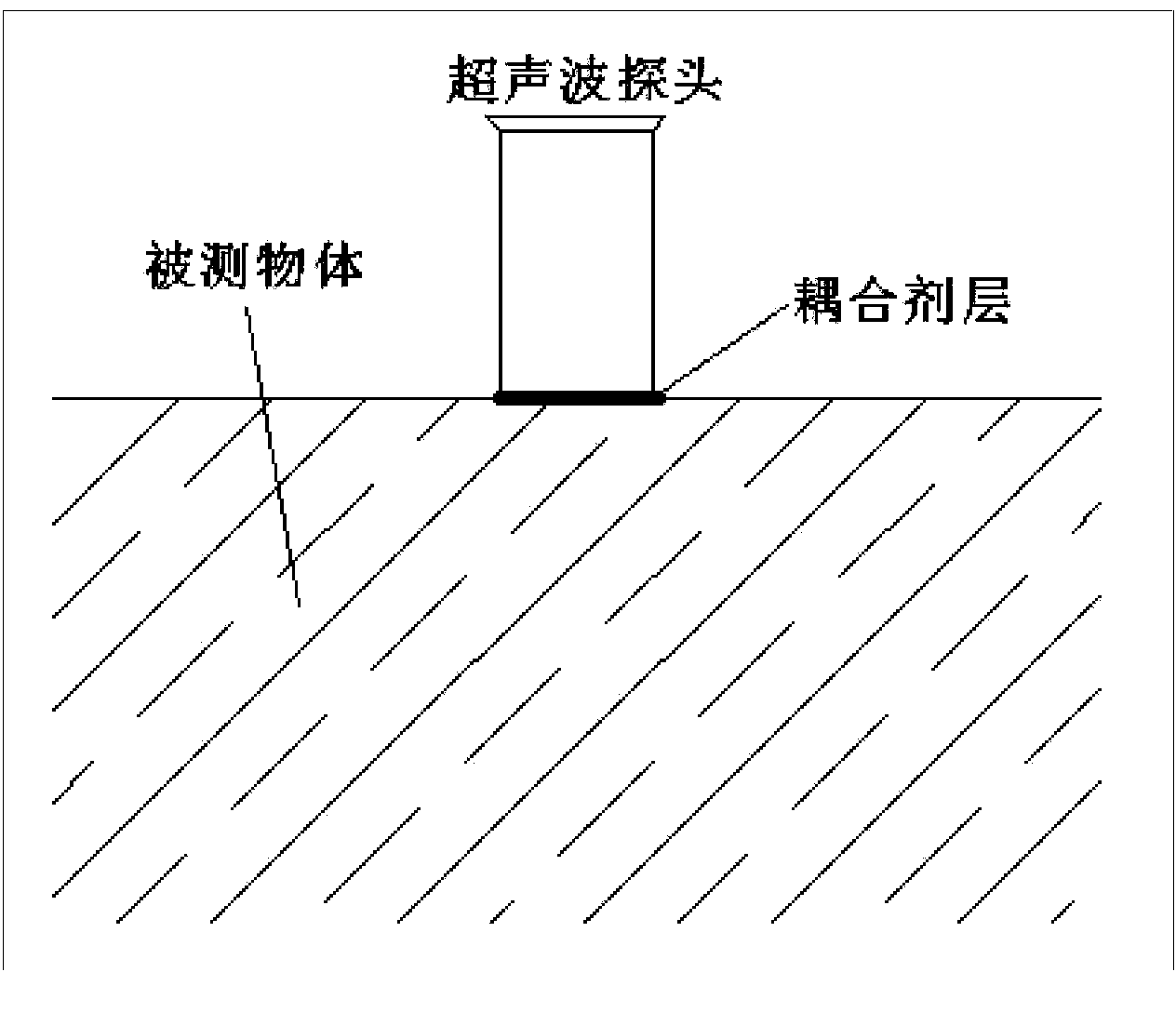

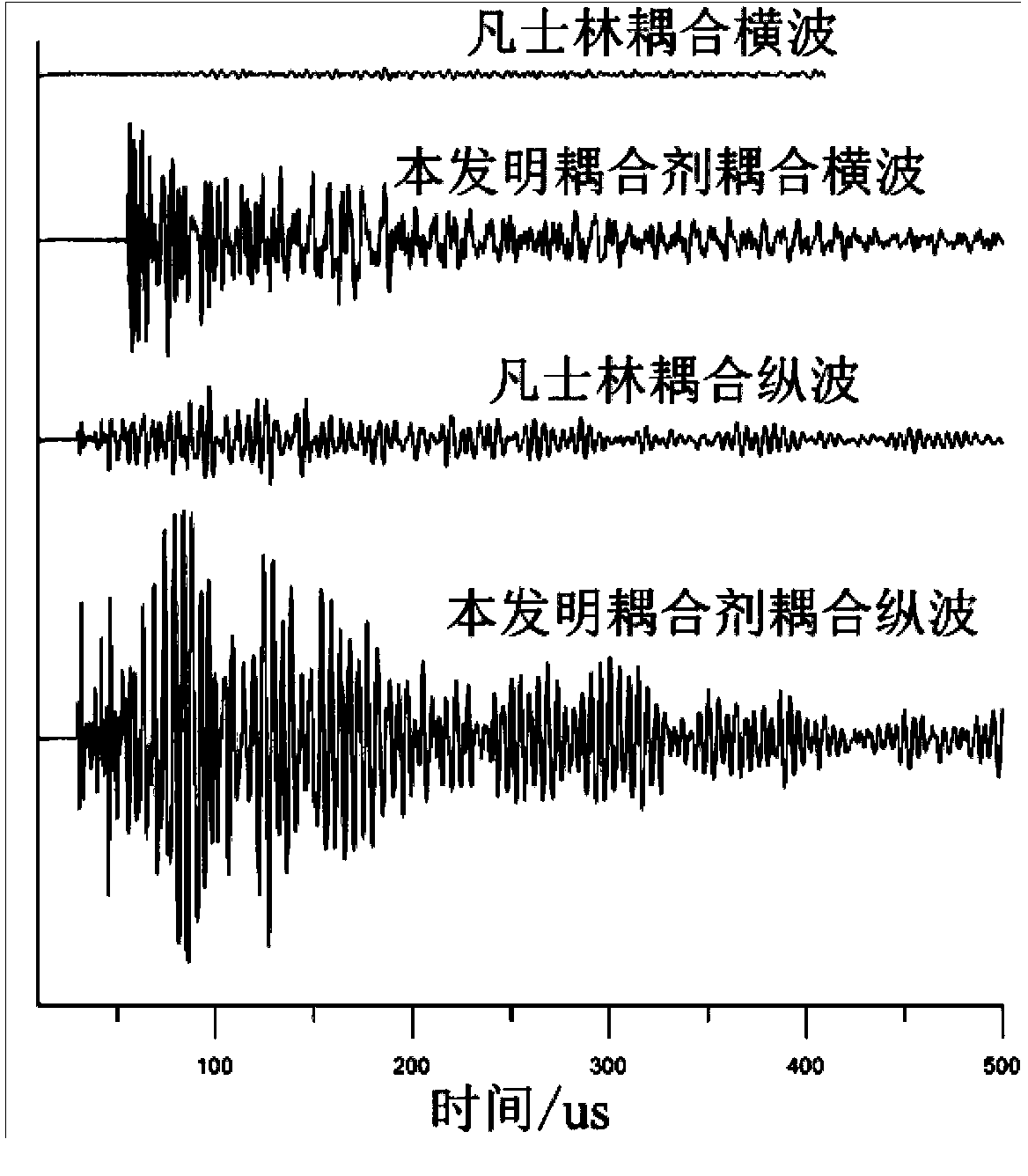

A couplant and roughness technology, which is applied in the field of couplant, can solve the problems of not being widely applicable, not being able to pass through shear waves, and poor coupling tightness, so as to reduce the cost of sample preparation and prevent the effect of too firm consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. A coupling agent that eliminates the influence of end surface roughness and improves the test effect of longitudinal and transverse waves, including:

[0030] Consolidator: Plaster of Paris CaSO 4 0.5H 2 O,

[0031] Consolidation strength modifier: raw gypsum CaSO 4 2H 2 O,

[0032] Lubricants and early strength agents: white latex, polyvinyl alcohol,

[0033] In severe cold areas, the mixed powder of magnesium chloride MgCl and calcium oxide CaO can also be used as a warming additive.

[0034] Described couplant making comprises the steps:

[0035] (1) Mix boiling water, 8% polyvinyl alcohol liquid glue and white latex in a ratio of 20:14:1 and stir fully to form a high-temperature diluted polyvinyl alcohol solution.

[0036] (2) Mix raw gypsum powder passed through a 0.075mm sieve with synthetic high-temperature liquid glue at a mass ratio of 3:2 to form a paste-like mixed reagent with a high consistency.

[0037] (3) After fully stirring the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com