CNT and silver nanometer wire recombination current expanding layer LED and manufacturing method thereof

A technology of light-emitting diodes and silver nanowires, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as large square resistance, low light transmittance, and restricted applications, and achieve low square resistance and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

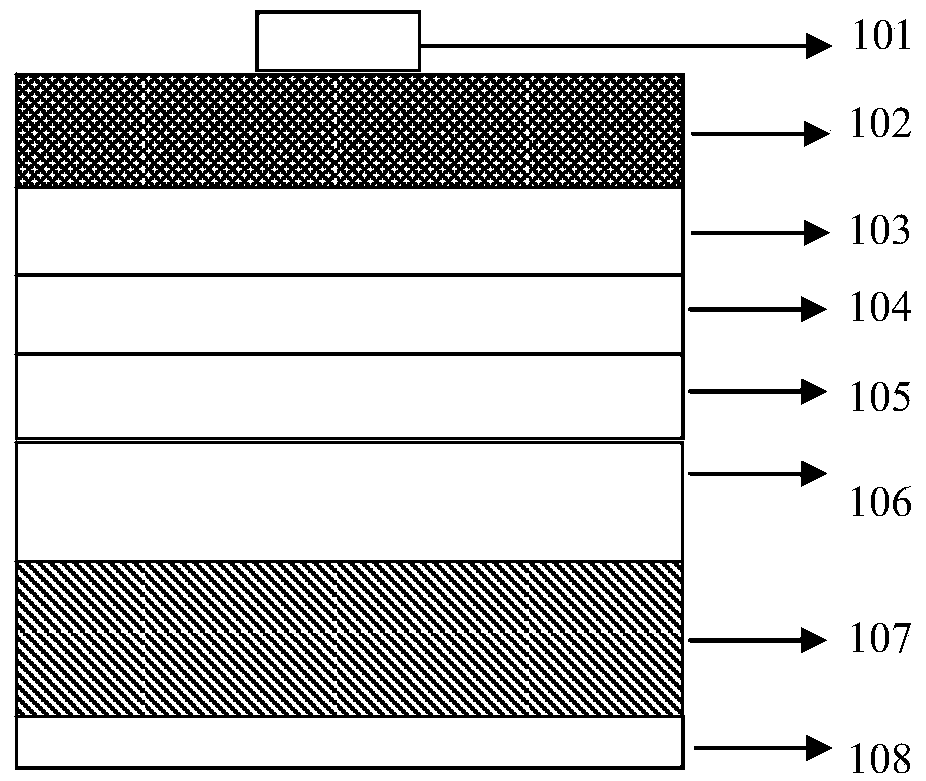

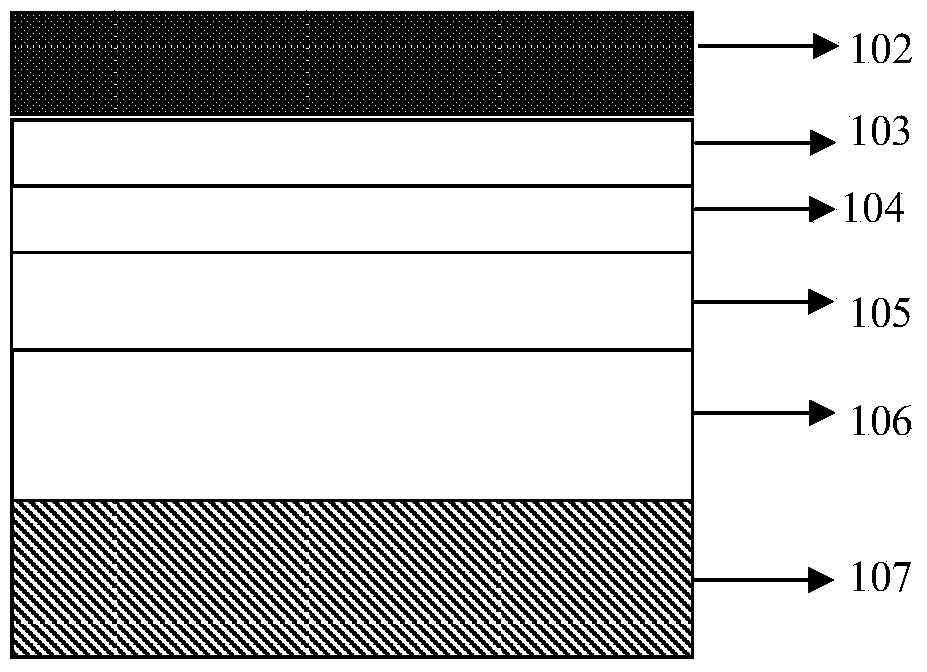

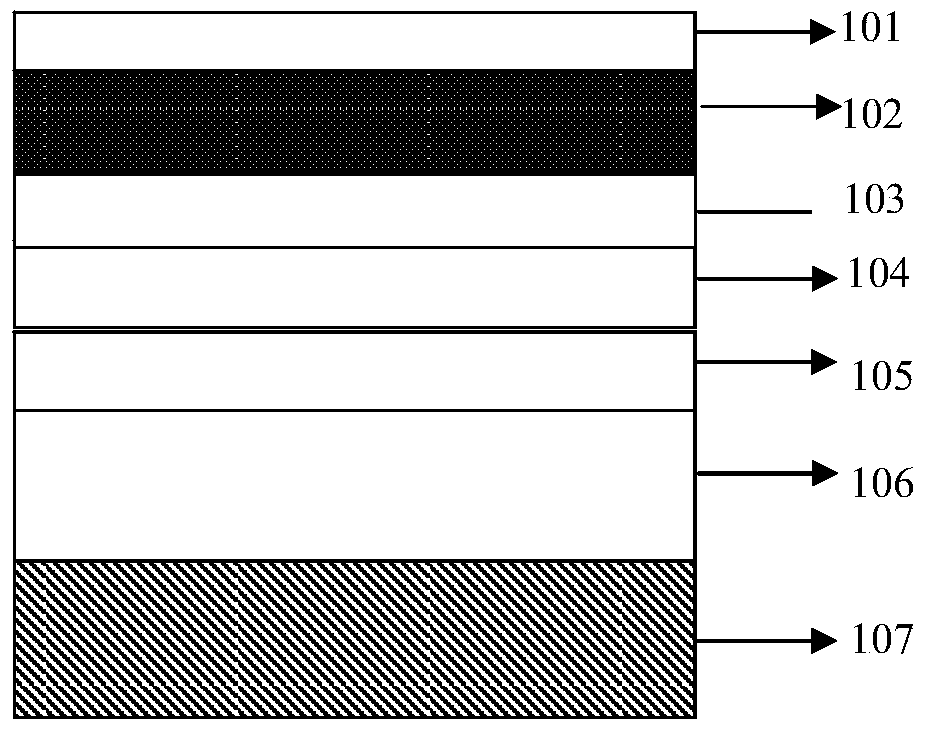

[0029] The preparation method of the carbon nanotube silver nanowire composite current spreading layer light emitting diode includes the following steps:

[0030] 1. First, an n-type current confinement layer 106, an active region 105, a p-type current confinement layer 104 and a window layer 103 are sequentially grown on a substrate by a metal organic chemical vapor deposition method;

[0031] 2. Laying carbon nanotubes on the window layer 103 by manual or machine stretching, the resulting carbon nanotube layer has a thickness of 80-100 nm, and a light transmittance of 85%-90%.

[0032] 3. The silver nanowires are suspended in isopropanol or other volatile solvents with a mass fraction of 1-2 mg / mL, and they are evenly covered on the surface of the carbon nanotube film by drip coating or suspension coating. In N 2 Under protection or heating under vacuum, the solvent is volatilized, and the silver nanowires are compounded on the current spreading layer of carbon nanotubes; the squar...

specific Embodiment approach 1

[0038] 1. First, an n-type current confinement layer 106, an active region 105, a p-type current confinement layer 104, and a window layer 103 are sequentially grown on a substrate by a metal organic chemical vapor deposition method;

[0039] 2. Lay carbon nanotubes on the window layer 103 by manual or machine stretching;

[0040] 3. The silver nanowires are suspended in isopropanol with a mass fraction of 2 mg / mL, and are uniformly covered on the surface of the carbon nanotube film by drip coating; the thickness of the obtained carbon nanotube layer is 80 nm, and the light transmittance is 85%.

[0041] 4. Then in N 2 It is heated to 70°C under protection to volatilize the solvent, and silver nanowires are compounded in the current spreading layer of carbon nanotubes. The square resistance of the carbon nanotube composite silver nanowire composite film is 50Ω / sq, and the light transmittance is 80%;

[0042] 5. Use photoresist as a mask, make electrode patterns with photoresist on the...

specific Embodiment approach 2

[0047] 1. First, an n-type current confinement layer 106, an active region 105, a p-type current confinement layer 104 and a window layer 103 are sequentially grown on a substrate by a metal organic chemical vapor deposition method;

[0048] 2. Laying carbon nanotubes on the window layer 103 by machine stretching; the resulting carbon nanotube layer has a thickness of 80 nm and a light transmittance of 90%.

[0049] 3. The silver nanowires are suspended in isopropanol with a mass fraction of 2mg / mL, and are evenly covered on the surface of the carbon nanotube film by suspension coating;

[0050] 4. Then heat to 70°C under vacuum to volatilize the solvent to obtain silver nanowires composited in the current spreading layer of carbon nanotubes. The square resistance of the carbon nanotube composite silver nanowire composite film is 50Ω / sq, and the light transmittance is 80%;

[0051] 5. Sputter or evaporate Ti / Au on the window layer 103, with a thickness of 15nm / 300nm, protect the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com