A method of making a hydrogen separation composite membrane

A technology for manufacturing gas and separation systems, applied in separation methods, hydrogen separation, diffusion hydrogen separation, etc., can solve problems that cannot meet industrial needs, damage functional manufacturing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

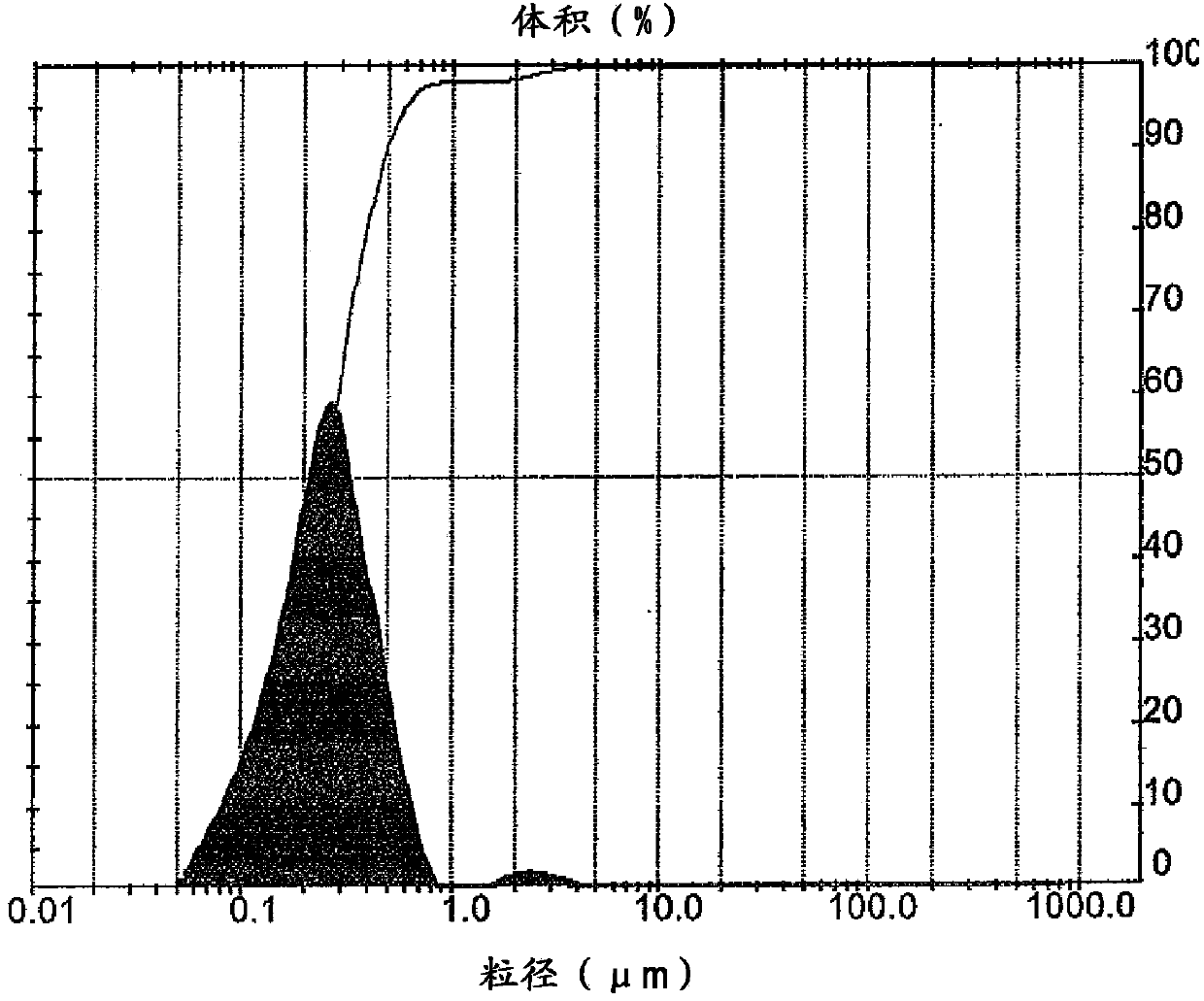

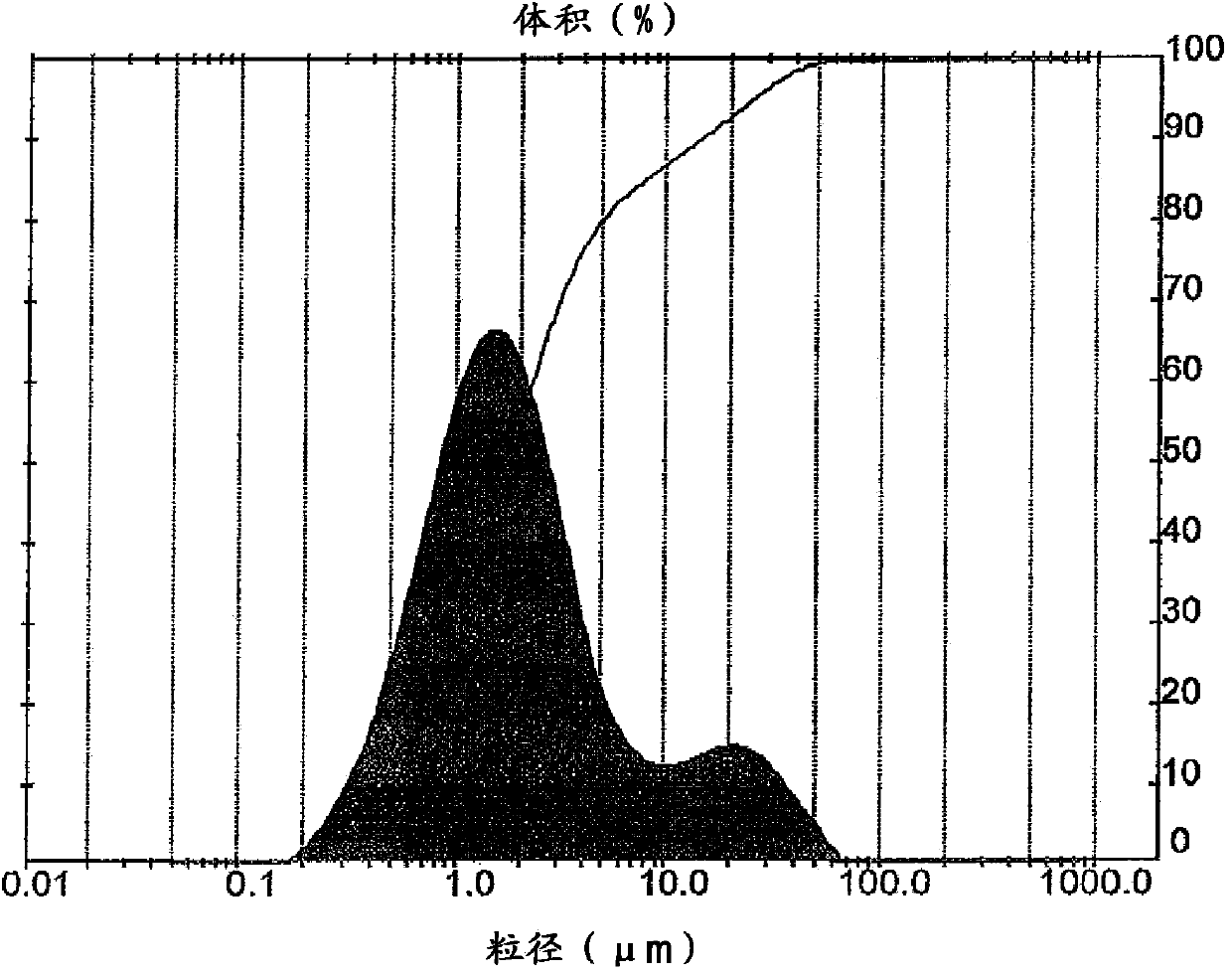

[0127] This example illustrates the reduction in surface roughness obtained by the method of the invention. In this example, an inside-out pressed cylindrical porous support made of 310 stainless steel was obtained from a commercial supplier. The initial surface roughness of the carrier was measured by using ST400 optical profilometer marketed and sold by Nanovea.RTM. Then make the vector with figure 2 The granular materials shown in were contacted using the slurry contact method described above. After removing excess particulate material, use figure 1 The granular material is subjected to a second contacting step. The surface roughness results are shown in Table 1.

[0128] Table 1

[0129]

[0130] After the particulate material contacting step, a thin film of palladium is deposited on the support treated with the sequential electroless plating and polishing steps as described above. The resulting gas separation system was then tested at 15 psi, showing 26m 3 / (...

Embodiment 2

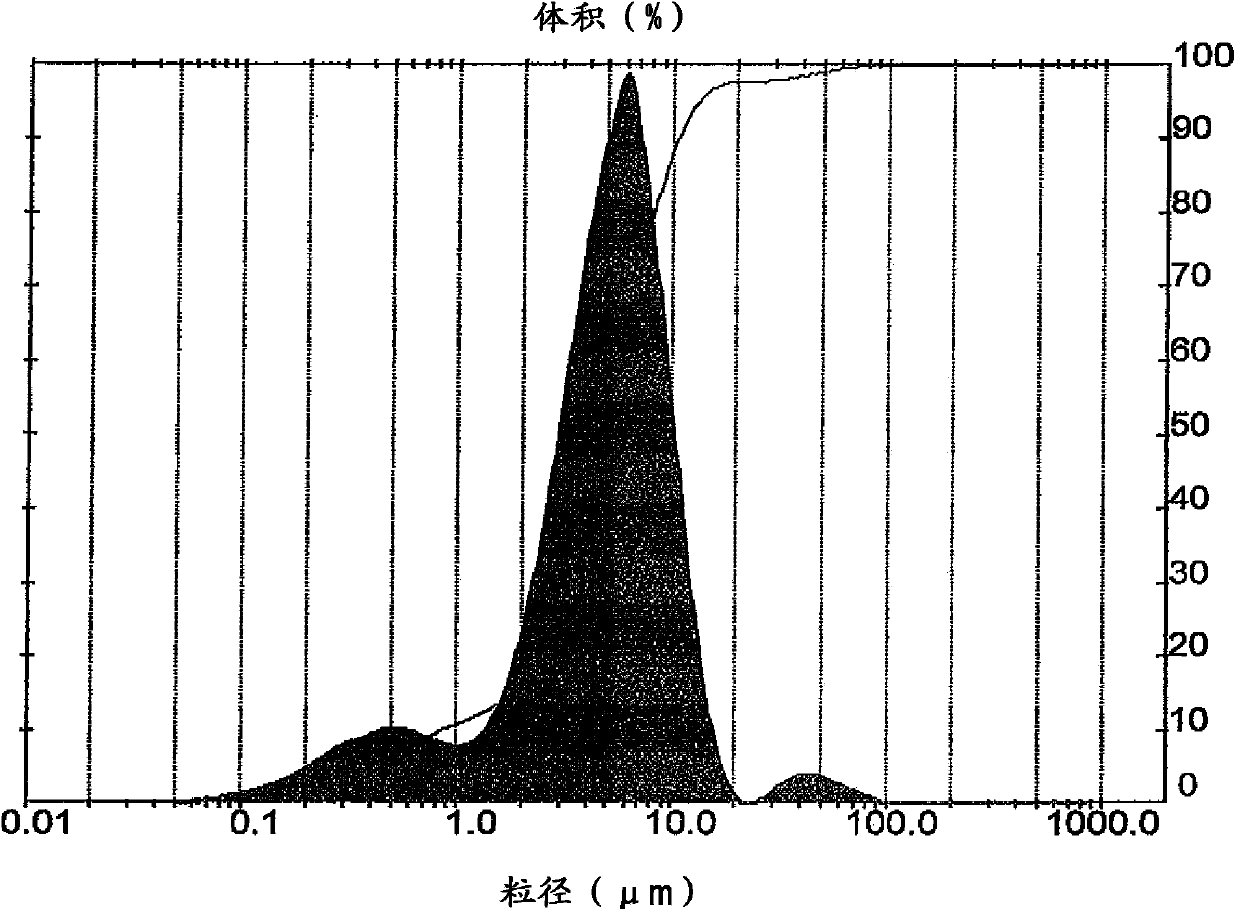

[0132] This example illustrates the reduction in surface roughness obtained by the method of the invention utilizing three contacting steps. In this example, an inside-out pressed cylindrical porous support made of 310 stainless steel was obtained from a commercial supplier. The initial surface roughness of the carrier was measured by using ST400 optical profilometer marketed and sold by Nanovea.RTM. Then make the vector with Figure 4 The granular materials shown in were contacted using the slurry contact method described above. use image 3 and 2 The exposure and associated steps were repeated two more times for the materials shown in . Surface roughness results are shown in Table 2.

[0133] Table 2

[0134]

[0135] After the particulate material contacting step, a thin film of palladium is deposited on the support treated with the sequential electroless plating and polishing steps as described above. The film has a 35.5m 3 / (m 2 hr bar) and did not show any ...

Embodiment 3

[0137] This example illustrates the reduction in surface roughness obtained by the method of the invention using four contacting steps as described above. In this example, an inside-out pressed cylindrical porous support made of 310 stainless steel was obtained from a commercial supplier. The initial surface roughness of the carrier was measured by using ST400 optical profilometer marketed and sold by Nanovea.RTM. Then make the vector with Figure 4 The granular materials shown in were contacted using the slurry contact method described above. use image 3 , 2 The exposure and associated steps were repeated three more times with the materials shown in 1. Surface roughness results are shown in Table 3.

[0138] table 3

[0139]

[0140] After the particulate material contacting step, a thin film of palladium is deposited on the support treated with the sequential electroless plating and polishing steps as described above. The membrane showed no leaks when pressurize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com