Resin particles and method for producing same, and method for controlling particle size of resin particles

A technology of resin particles and manufacturing methods, which is applied in the field of particle size and particle size adjustment, can solve the problems of tiny particles, processing hindrance, and reaction solution processing problems, and achieve the effect of high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

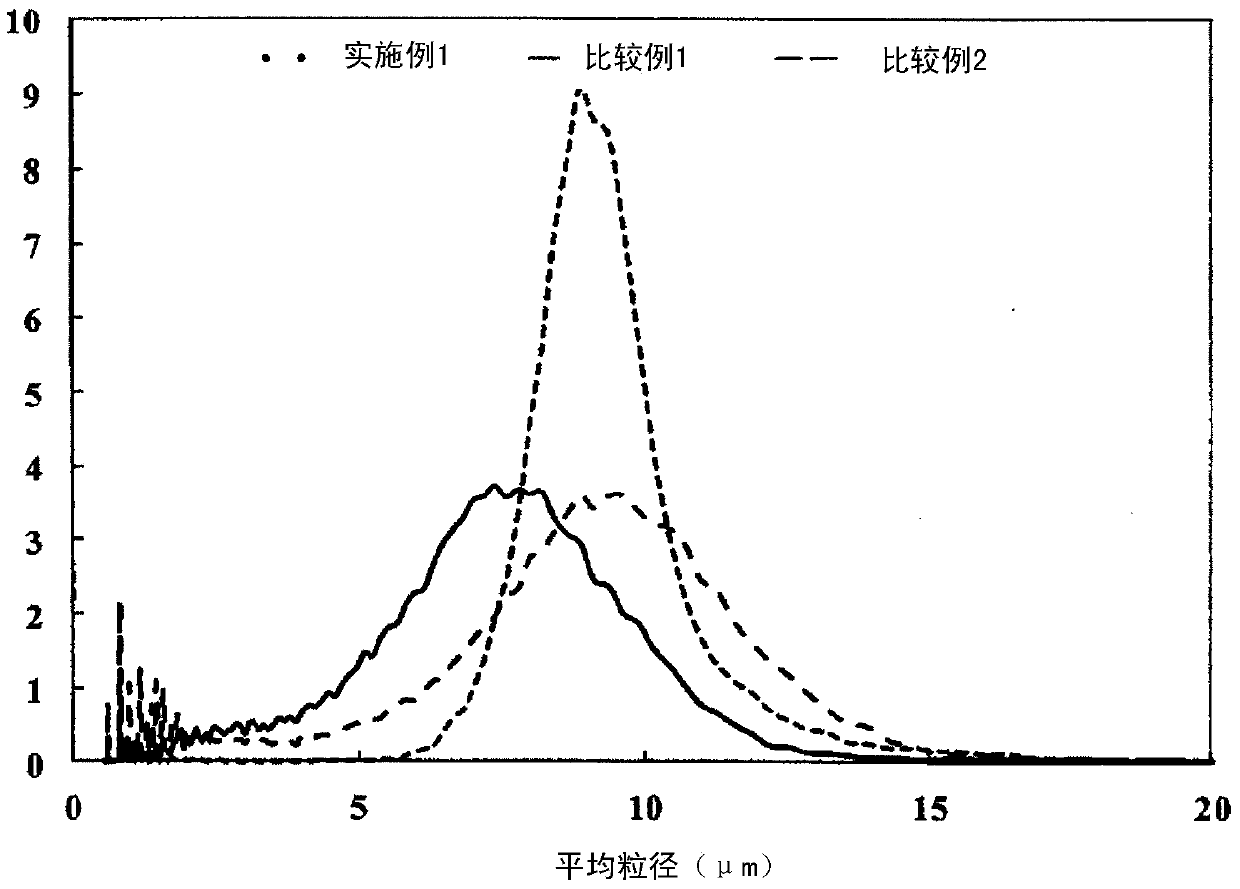

Image

Examples

Embodiment 1

[0125] 70 parts by weight of methyl methacrylate and 30 parts by weight of trimethylolpropane triacrylate were added to a glass flask with a capacity of 1 liter, and mixed well. 0.7 weight part of sorbitan laurate (HLB value: 8.6) was added there, and it stirred and melt|dissolved. Next, 0.5 parts by weight of lauroyl peroxide was added, stirred and dissolved sufficiently, and a polymerizable oily monomer solution was prepared.

[0126] 80 parts by weight of ion-exchanged water was added to the above-mentioned polymerizable oily monomer solution, and the obtained mixed phase was stirred at 13000 rpm (peripheral speed: 19.2 m / sec) for 1 minute with a homomixer to obtain an emulsion. To this emulsion was added an aqueous solution obtained by dissolving 1.0 parts by weight of polyvinyl alcohol (manufactured by Kuraray Co., Ltd.: product name PVA-224) in 180 parts by weight of tap water. °C for 3 hours to obtain a resin particle dispersion.

[0127]After the obtained resin parti...

Embodiment 2

[0129] 70 parts by weight of methyl methacrylate and 30 parts by weight of trimethylolpropane triacrylate were added to a glass flask with a capacity of 1 liter, and mixed well. 0.6 weight part of sorbitan laurate (HLB value: 8.6) was added there, and it stirred and melt|dissolved. Next, 0.5 parts by weight of lauroyl peroxide was added, stirred and dissolved sufficiently, and a polymerizable monomer solution was prepared.

[0130] Add 80 parts by weight of ion-exchanged water, 0.3 parts by weight of colloidal silicon dioxide, and polyvinyl alcohol (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd. (Daiichi Kogyo Pharmaceutical Co., Ltd.): trade name PITZCOL V- 7154) 0.01 part by weight, and the obtained mixed phase was stirred at 13000 rpm (peripheral speed: 19.2 m / sec) for 1 minute with a homomixer to obtain an emulsion. To this emulsion was added an aqueous solution obtained by dissolving 1.0 parts by weight of polyvinyl alcohol (manufactured by Kuraray Co., Ltd.: tra...

Embodiment 3

[0133] 70 parts by weight of methyl methacrylate, 30 parts by weight of trimethylolpropane triacrylate, and 0.3 parts by weight of 4-hydroxybutyl acrylate were added to a glass flask with a capacity of 1 liter, and mixed well. 0.3 weight part of sorbitan laurate (HLB value: 8.6) was added there, and it stirred and melt|dissolved. Next, 0.5 parts by weight of lauroyl peroxide was added, stirred and dissolved sufficiently, and a polymerizable monomer solution was prepared.

[0134] 60 parts by weight of ion-exchanged water, 0.1 part by weight of colloidal silica, and 0.1 part by weight of polyvinyl alcohol (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.: trade name PITZCOL V-7154) were added to the above-mentioned polymerizable monomer solution. The mixed phase was stirred at 8000 rpm (peripheral speed: 11.7 m / sec) for 1 minute with a homomixer to obtain an emulsion. To this emulsion was added an aqueous solution obtained by dissolving 1.0 parts by weight of polyvinyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com