Working platform for high-strength steel welding process research with welding robot

A welding robot, high-strength steel technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing welding quality, easy to cause overheating, difficult to change, etc., to improve work efficiency and alleviate labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

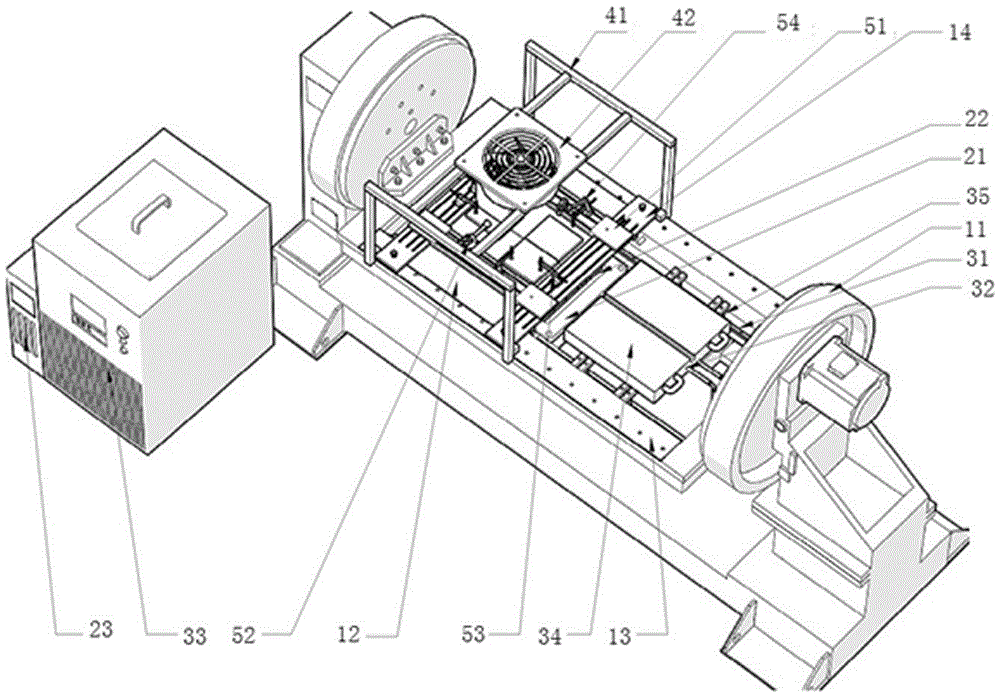

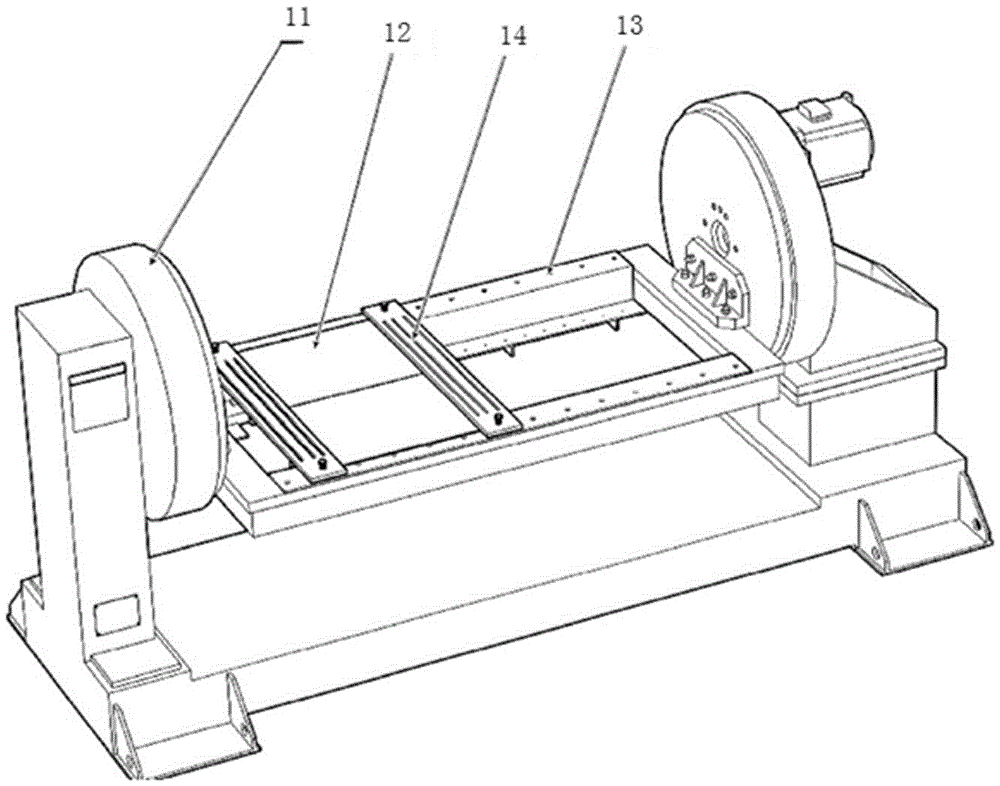

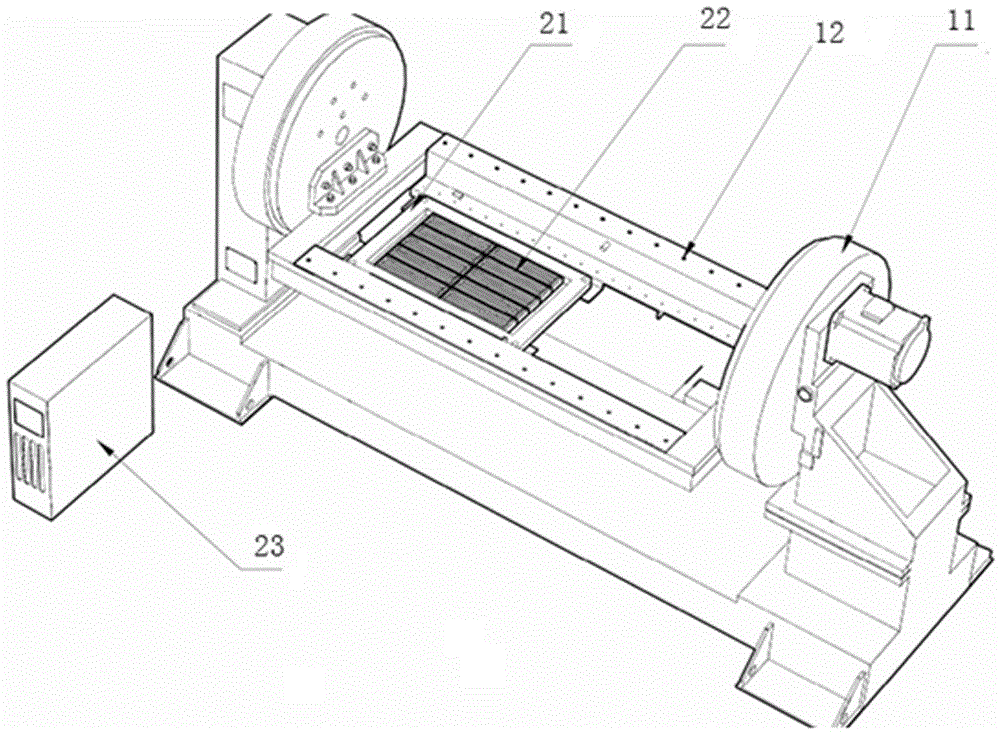

[0058] Such as figure 1 As shown, a working platform that cooperates with a welding robot for high-strength steel welding process research includes: platform components, which include a platform base 11, a platform plate 12 arranged on the platform base 11, and arranged on both sides of the platform plate 12 The guide rail supporting frame 13, and a pair of platform pressing plates 14, wherein one described platform pressing plate 14 is positioned on the guiding rail supporting frame 13, and another platform pressing plate 14 is positioned on the platform plate 12, and platform pressing plate 14 two ends have positioning drilling, The purpose is to connect the guide rail support frame 13, and there are 3 linear notches in the middle position, which are used to install the fixture (see figure 2 ); a heating modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com