Silicon-based group III-V nanotubes and micro-tubes as well as preparation method thereof

A III-V and microtube technology, applied in the field of nanotube and microtube materials and their preparation, can solve the problems of tube structure defects, high control cost, uncontrollable and other problems, achieve controllable number of tube wall circles, and improve luminous quality , The effect of fast tube making speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

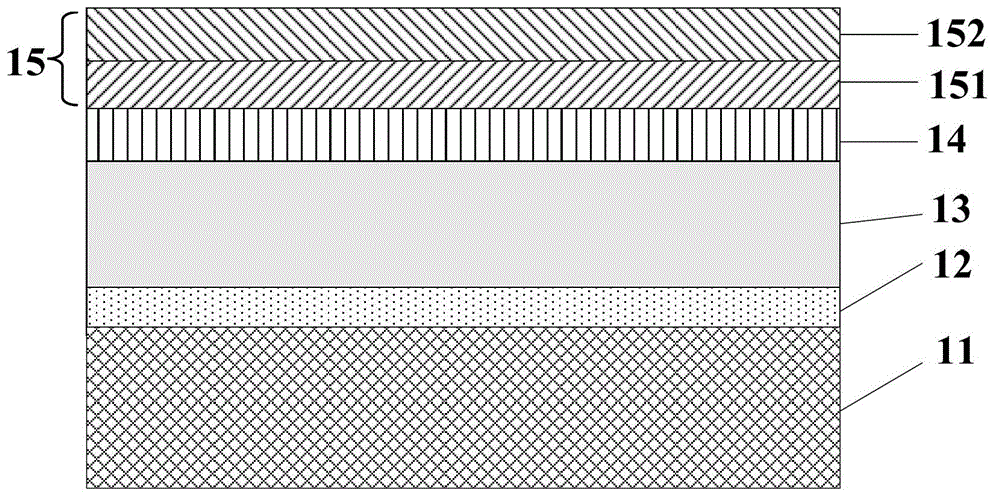

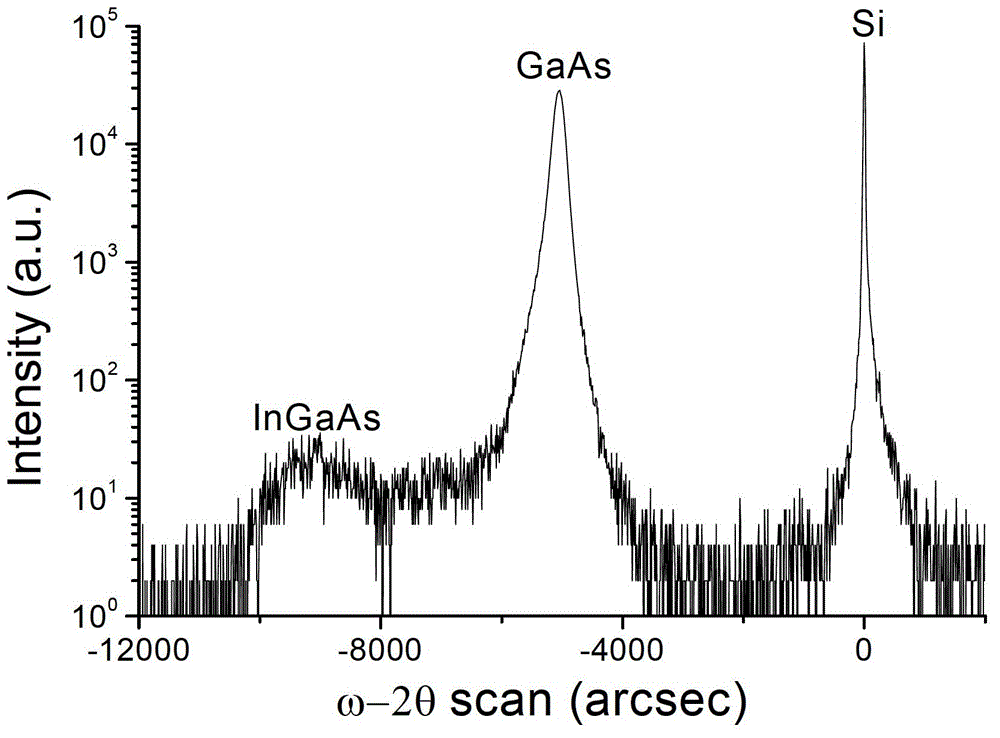

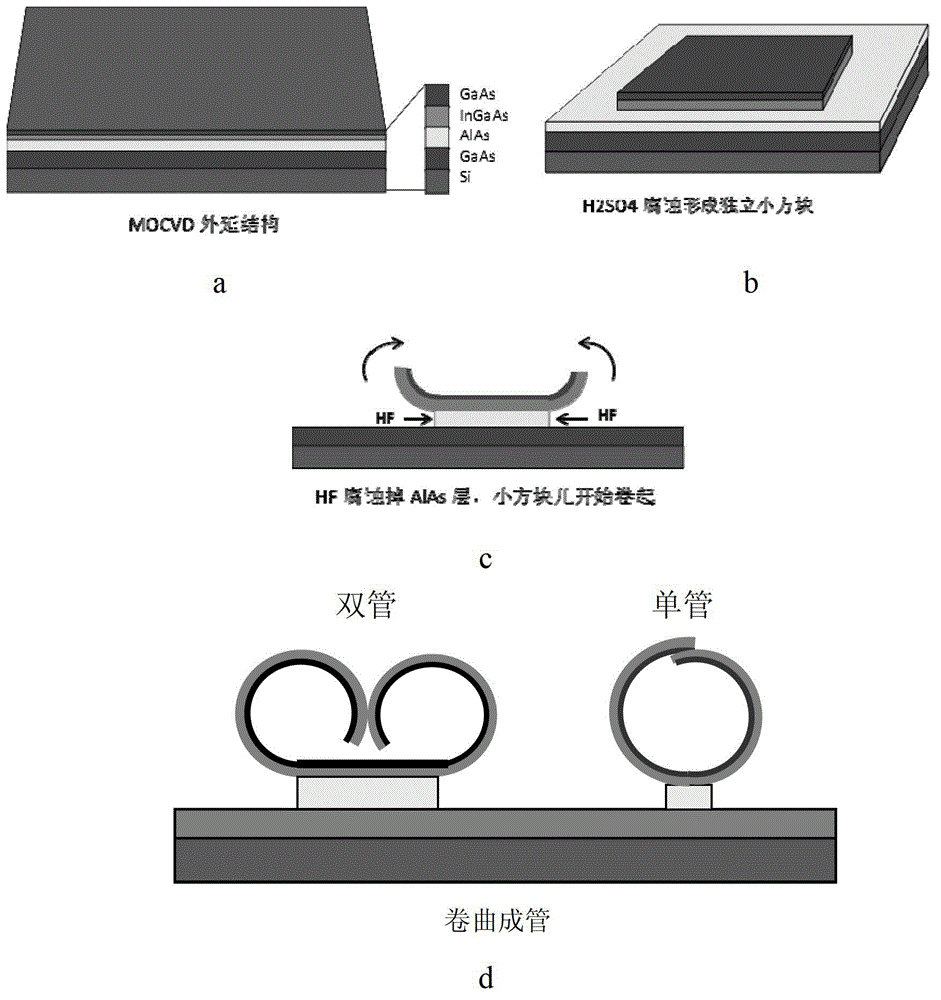

[0053]Embodiment 1: Preparation of III-V group InGaAs / GaAs microtubes on Si(100) substrate

[0054] S1: Clean the single crystal Si substrate and remove the oxide layer on the Si surface, and then epitaxially grow the abnormal buffer layer on the single crystal Si substrate;

[0055] RCA cleaning is performed on the Si sheet, and the oxide layer on the surface of the Si(100) substrate is removed by hydrofluoric acid (HF). Finally, the Si substrate is placed in the MOCVD reaction chamber after cleaning with deionized water and drying.

[0056] Warming up to 750°C, under H 2 Bake the Si sheet under the atmosphere for 30 minutes, and then pass the AsH at the same temperature 3 Passivate for 30 minutes.

[0057] Cool down to 420°C, using trimethyl (TMGa), arsine (AsH 3 ) to grow a low temperature GaAs nucleation layer (Low temperature GaAs nucleation layer), with a thickness of 70nm and a V / III ratio controlled at 250.

[0058] Heating up to 630°C, using TMGa, AsH 3 Grow an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com